Omnibearing dynamic deformation test monitoring device

A dynamic deformation and monitoring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to obtain the overall deformation information of components, low measurement accuracy and repeatability, and inability to measure the overall components, etc., to reduce Effects of installation time and labor costs, avoiding inaccurate measurement of deformation data, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

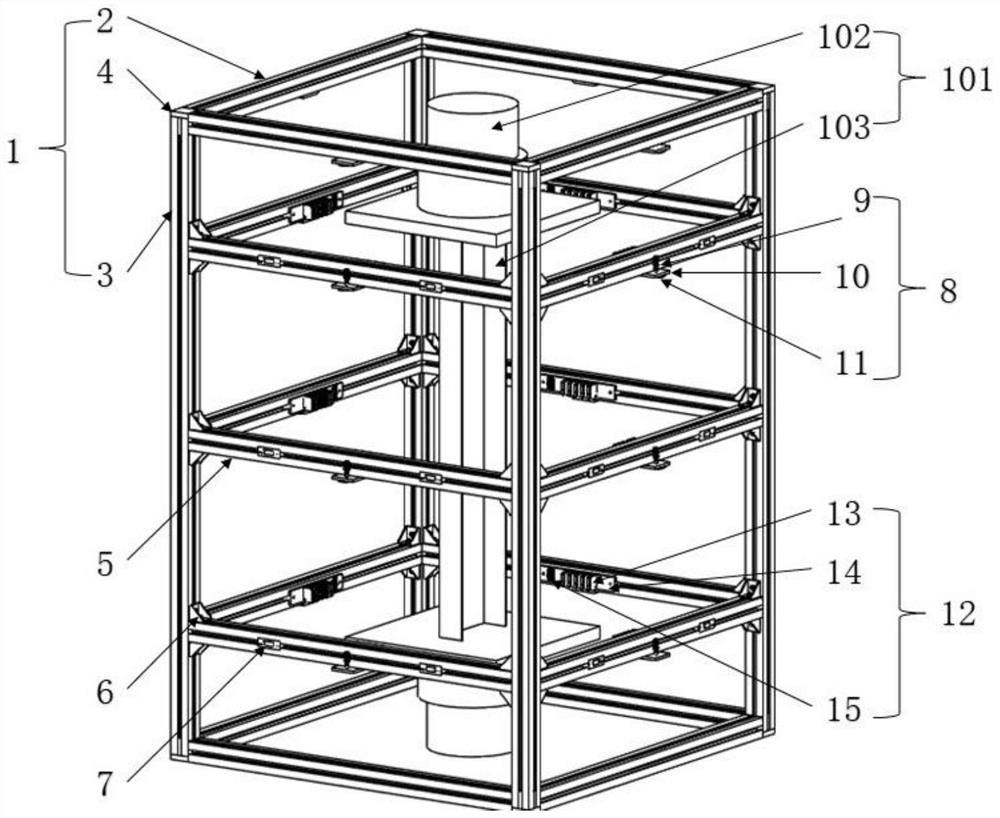

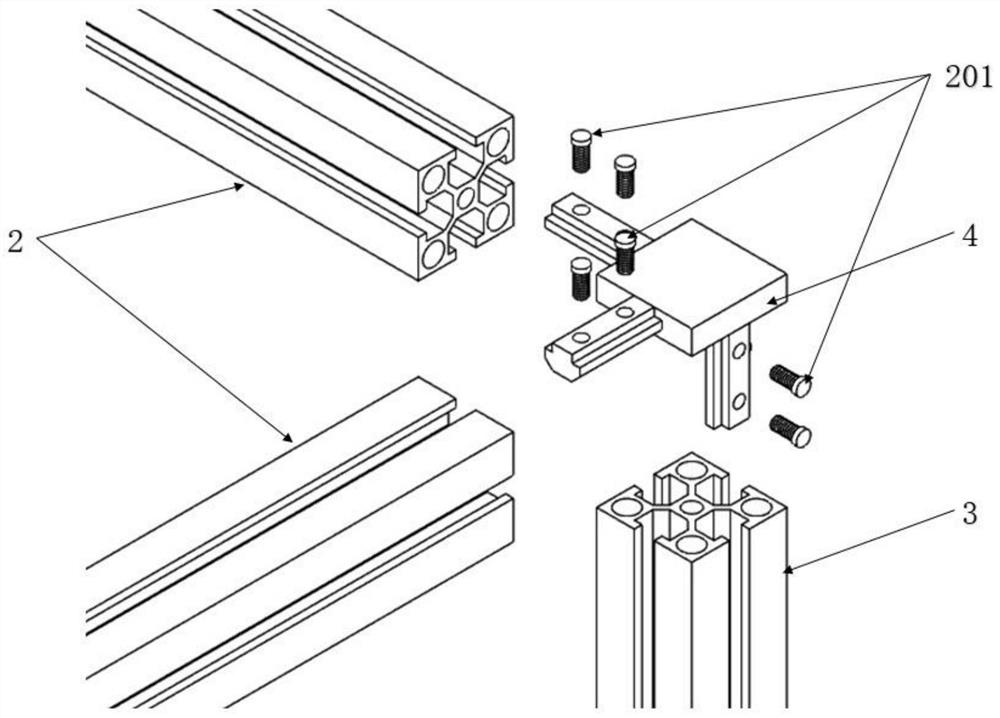

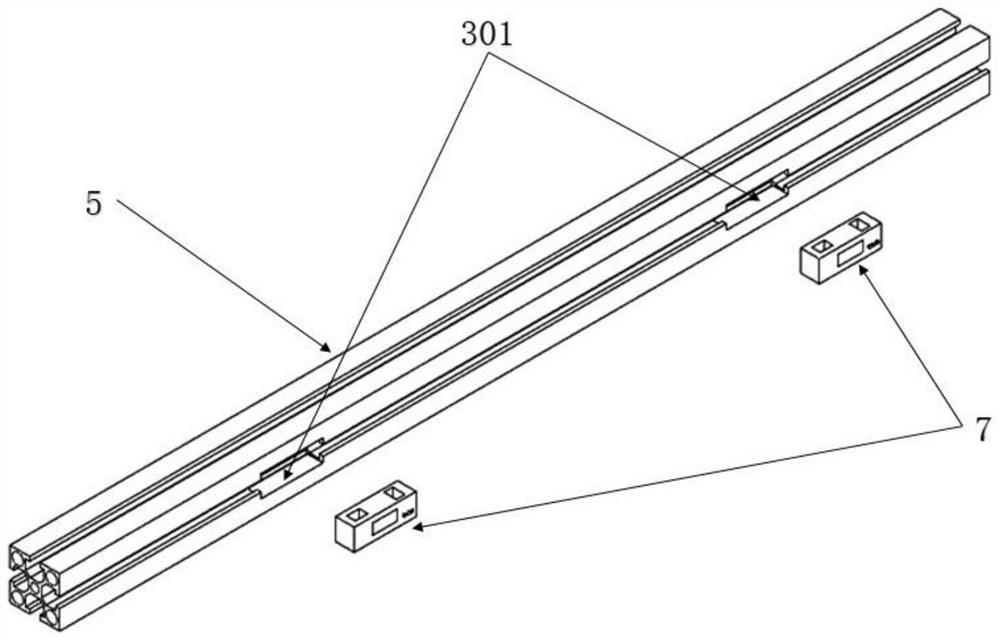

[0037] like Figure 1 to Figure 5 As shown, the present invention provides a kind of all-round dynamic deformation test monitoring device, comprises frame beam 2, frame column 3, frame connector 4 to form fixed frame 1, can assemble measuring arm 5 and be installed on the fixed frame through measuring arm connector 6 1, the electronic level 7 is used to ensure the level of the assembling measuring arm 5, the acoustic wave distance measuring sensor 9, the sound wave device fixing plate 10, and the sound wave reflecting plate 11 together form the acoustic wave positioning mechanism 8, the laser distance measuring sensor 13, and the laser device fixing plate 14. The data acquisition board 15 togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com