High-pressure main steam combined valve capable of locally reducing stress and stress analysis method

A technology of stress analysis and combined valves, which is applied in the direction of steam traps, valve details, valve devices, etc., can solve the problems that cracks around the drain holes cannot be prevented, and achieve the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

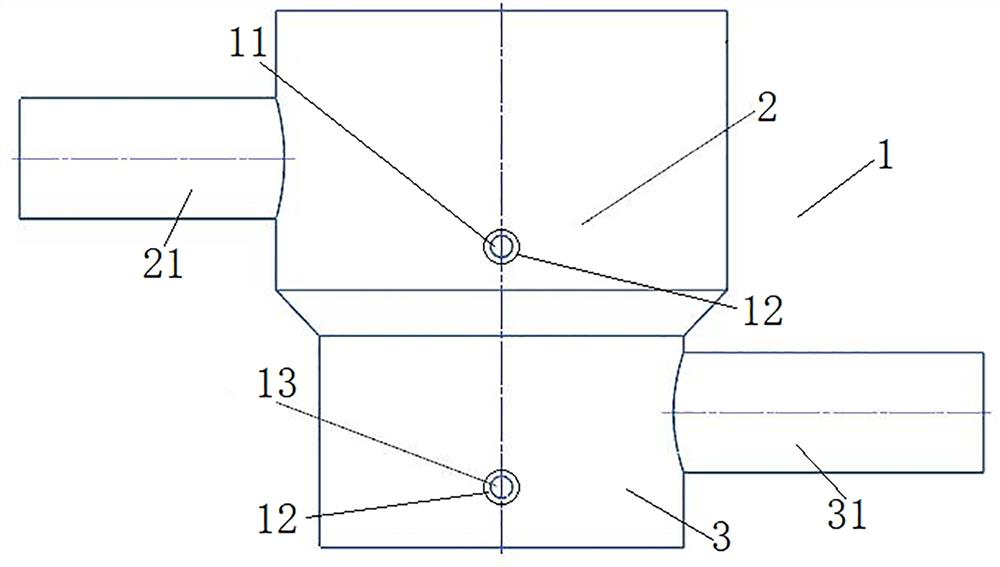

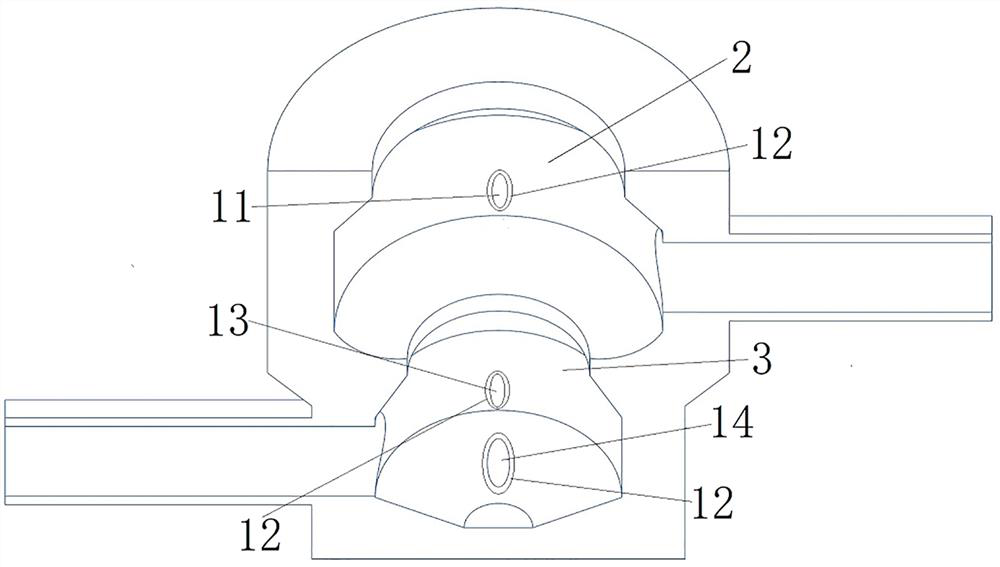

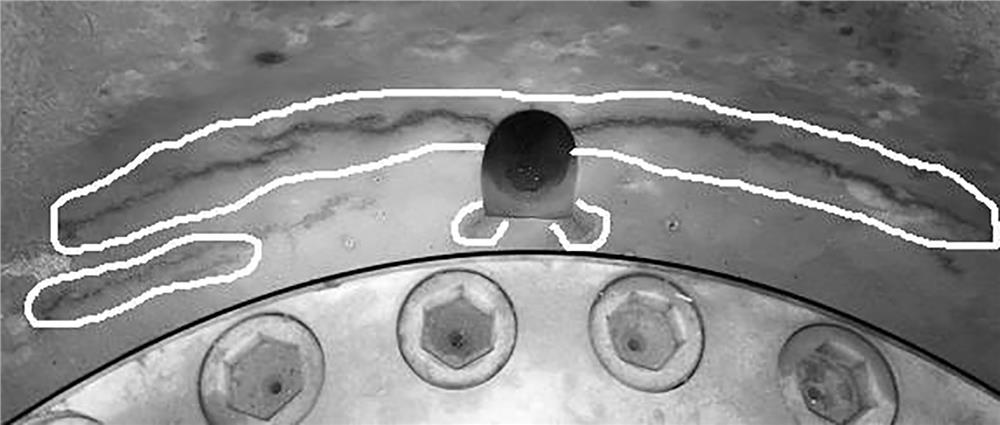

[0057] Embodiment 1. In this embodiment, if Figure 1 to Figure 2As shown, a high-pressure main steam combined valve for locally reducing stress includes: a valve body 1, and at least one pre-valve drain hole 11 is opened on the valve body 1, and the pre-valve drain hole 11 and the valve body 1 pass through the transition Round edges 12 are connected.

[0058] The present invention is further set as: the valve body 1 is integrally formed, the valve body 1 includes a regulating valve body 2 and a main steam valve body 3 communicating with the regulating valve body, the regulating valve body 2 is connected with the regulating valve body The sides of the main steam valve body 3 are respectively connected with a steam inlet pipe 21 and a steam outlet pipe 31, and the drain hole 11 before the valve is opened on the side wall of the regulating valve body 2; the valve body 1 is also provided with at least A steam trap 13 after the valve and at least one steam leakage trap 14 for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com