Skin material for electric heating anti-icing and deicing of airplane, and preparation method thereof

A kind of skin material and electric heating technology, applied in the direction of chemical instruments and methods, lamination, layered products, etc., can solve the problems of uneven and uneven distribution of fracture temperature, flexibility and heating temperature of metal components, so as to improve toughness, The deicing effect remains unchanged and the fluidity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The disclosed embodiments of the present invention propose a method for preparing a skin material for electrothermal anti-icing of aircraft, including:

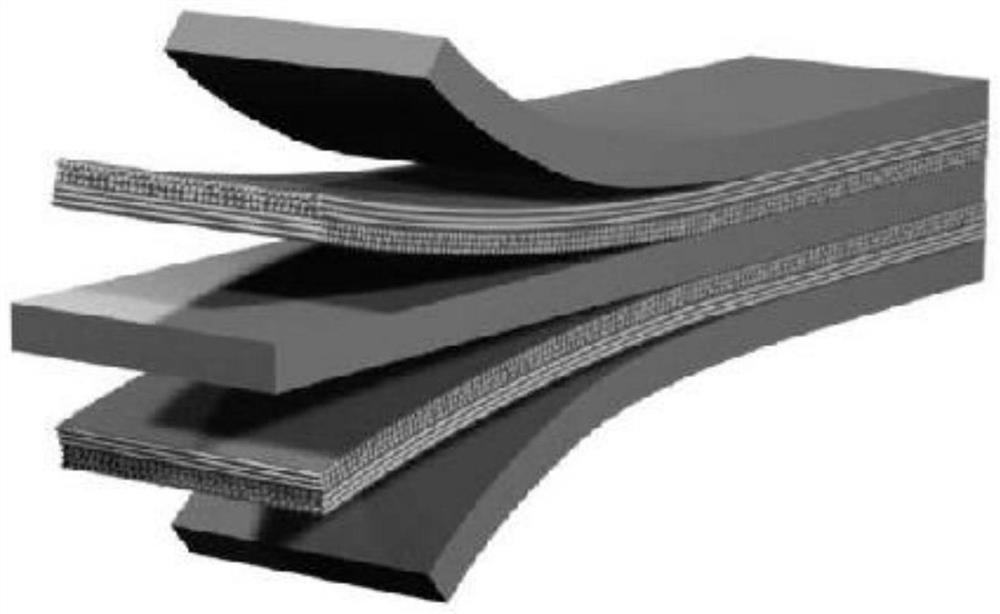

[0042] Step 2. Use reduced graphene oxide (RGO) to modify epoxy resin to obtain modified carbon fiber reinforced resin composite material (R@CFRP), and on this basis, compound with titanium alloy plate to prepare modified titanium plate / carbon fiber Reinforced resin composites (R@Ti / CFRP).

[0043] Preferably, in described step 1, prepare reduced graphene oxide (RGO) based on flake graphite material, comprising:

[0044] Low-temperature reaction: combining flake graphite and NaNO 3 Put it into a 1L beaker, add 150mL concentrated sulfuric acid under ice bath conditions, stir and react for 15min, weigh the KMnO 4 , added to the flask in batches under the condition of constant stirring, and controlled the reaction temperature at 5°C;

[0045] Medium temperature reaction: to be KMnO 4 After adding everything, react for...

Embodiment 1

[0071] (1) Preparation of reduced graphene oxide (RGO)

[0072] Low temperature reaction: 6g flake graphite and 3g NaNO 3 Put it into a 1L beaker, add 150mL concentrated sulfuric acid under ice bath conditions, stir and react for 15min, weigh 18gKMnO 4 , added to the flask in batches (once every 15 minutes) under the condition of constant stirring, and controlled the temperature at about 5°C.

[0073] Medium temperature reaction: to be KMnO 4 After adding everything, react for 120 minutes, then transfer the beaker to a water bath at 35°C and continue stirring. When the liquid becomes viscous (about 120 minutes), add 200 mL of deionized water into the beaker; keep the temperature at this stage and continue the reaction for 120 minutes.

[0074] High temperature reaction: heat up to 98°C; then add 400mL deionized water to dilute, cool down and add 30% hydrogen peroxide to reduce excess potassium permanganate until no bubbles are generated and the solution is bright yellow. Wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com