Automobile covering part storage equipment

A technology for automobile covers and equipment, which is applied to vehicle parts, wheels, internal accessories, etc., can solve the problems of humidity changes in indoor space, inconvenient moving and handling, and rusting of cover parts due to moisture, so as to facilitate fixed transportation and easy placement. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

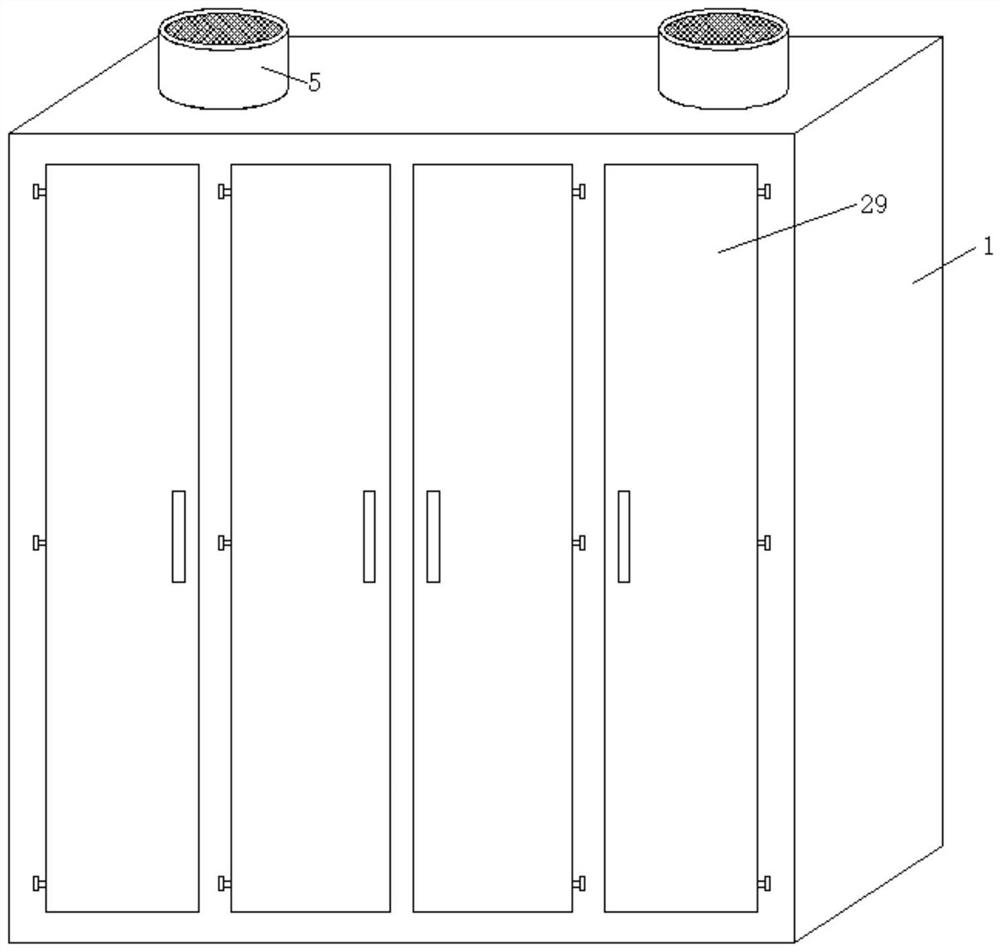

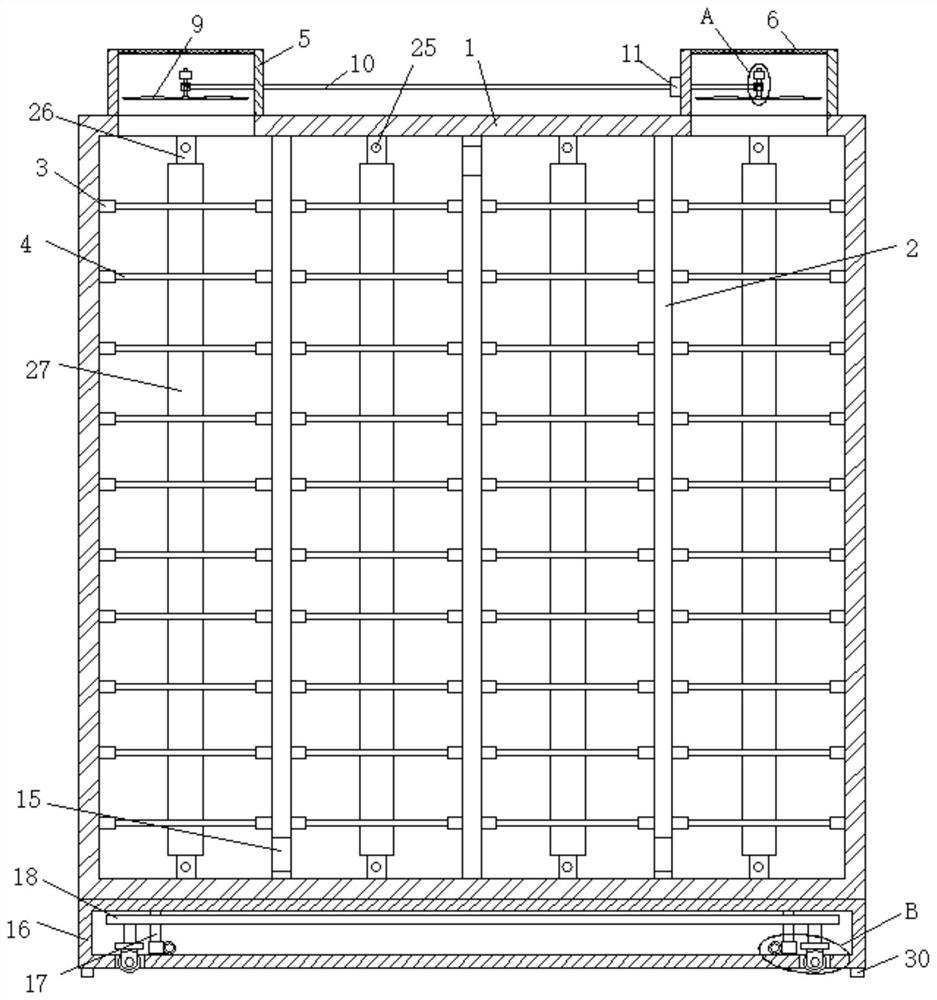

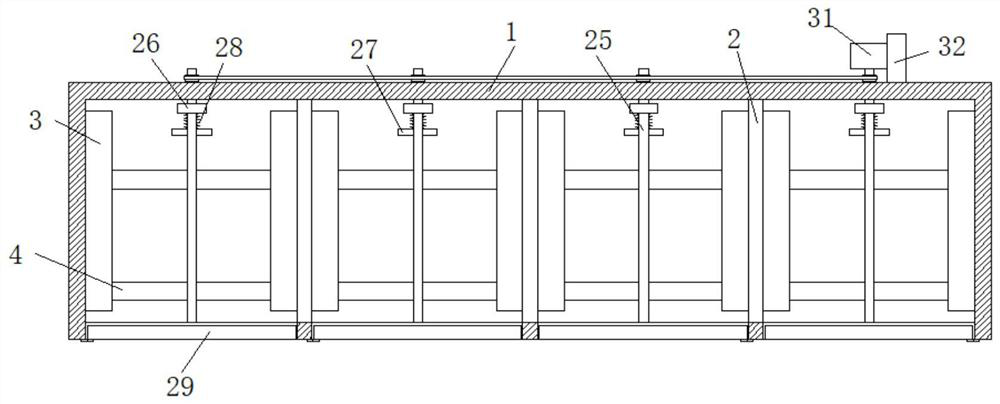

[0023] refer to Figure 1-5 , a kind of automobile cover storage equipment, comprises a cabinet body 1, three partitions 2 equally divided are fixedly installed on the inner wall of the cabinet body 1, and a plurality of Positioning plate 3, two connecting rods 4 are fixedly installed between the corresponding two positioning plates 3, and two symmetrical fixed boxes 5 are fixedly installed on the top of the cabinet body 1, and the fixed box 5 is provided with an air guide mechanism, which is fixed One side of the box 5 is fixedly equipped with a biaxial motor 11, and the output shaft of the biaxial motor 11 is fixedly equipped with a transmission rod 10. The transmission rod 10 is rotatably connected with the two fixed boxes 5, and the transmission rod 10 is connected with the air guiding mechanism. A through hole 15 is provided on the partition 2, a housing 16 is fixedly installed on the bottom of the cabinet body 1, and four symmetrically arranged backing plates 30 are fixe...

Embodiment 2

[0029] refer to Figure 1-5 , a kind of automobile cover storage equipment, comprises a cabinet body 1, three partitions 2 equally divided are fixedly installed on the inner wall of the cabinet body 1, and a plurality of Positioning plate 3, two connecting rods 4 are fixedly installed between the corresponding two positioning plates 3, and two symmetrical fixed boxes 5 are fixedly installed on the top of the cabinet body 1, and the fixed box 5 is provided with an air guide mechanism, which is fixed One side of the box 5 is fixedly equipped with a biaxial motor 11, and the output shaft of the biaxial motor 11 is fixedly equipped with a transmission rod 10. The transmission rod 10 is rotatably connected with the two fixed boxes 5, and the transmission rod 10 is connected with the air guiding mechanism. A through hole 15 is provided on the partition 2, a housing 16 is fixedly installed on the bottom of the cabinet body 1, and four symmetrically arranged backing plates 30 are fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com