Automatic ton bag opening machine

A technology for unpacking machines and ton-bags, which is applied in the field of automatic ton-bag unpacking machines, which can solve problems such as low efficiency, human damage, and high labor intensity, so as to improve efficiency and safety, reduce dust generation, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

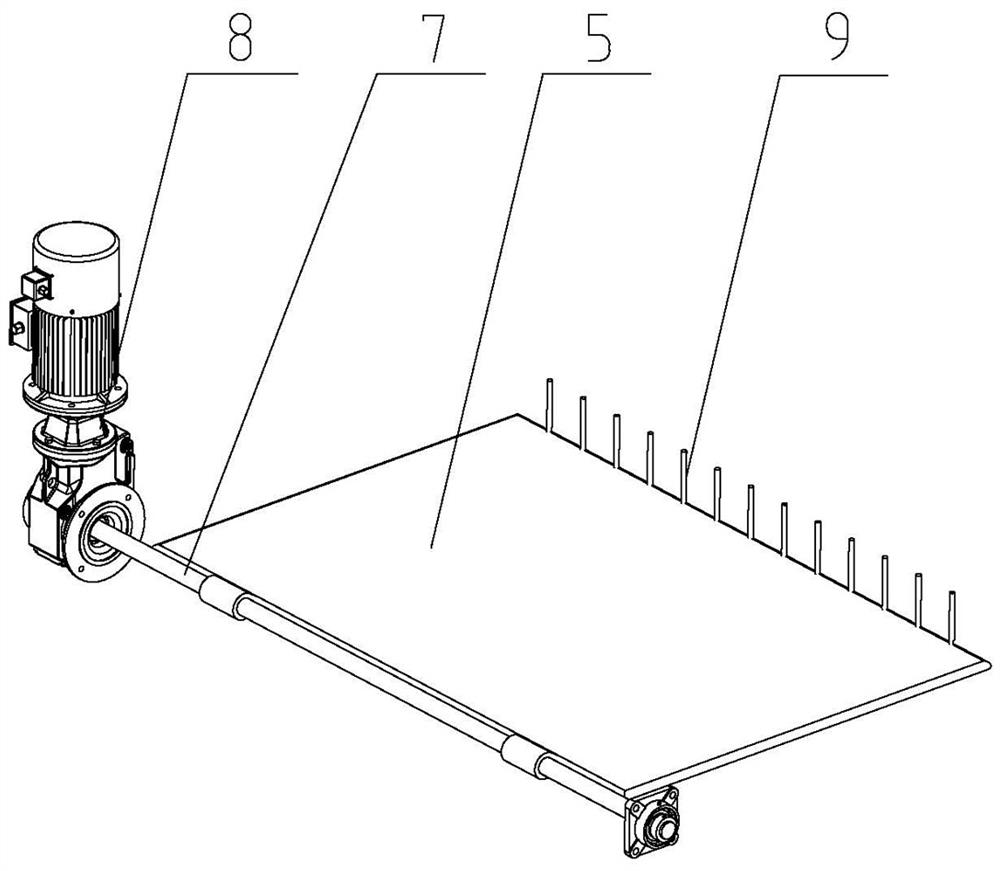

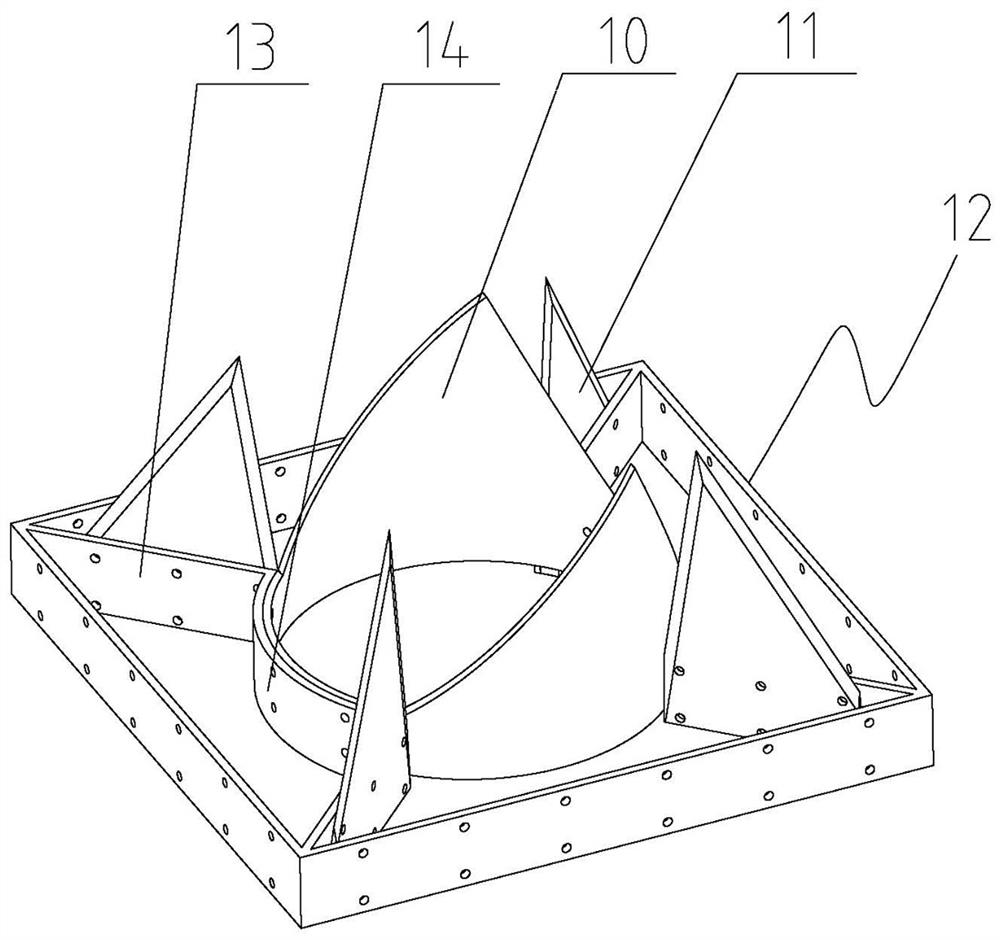

[0018] See Figure 1 to Figure 6 As shown, an automatic bag opening machine for ton bags includes a bag opening bin 1, a bag collecting bin 2, and a hanger 17 for suspending ton bags 16. The bag opening bin 1 and bag collecting bin 2 are generally arranged side by side and integrated into a Integrated to reduce the space occupied by the workshop and the generation of dust. The bag breaking tool 3 is installed in the bag opening bin 2, the bottom of the bag opening bin 1 is connected to the discharge bin 4, and the reversible pressure plate 5 is installed in the bag collecting bin 2. The bag collecting bin 2. A waste bag collection mechanism 6 is provided at the bottom. In order to improve automation efficiency, the waste bag collection mechanism 6 includes a waste collection frame and communicates with the AGV trolley through a wireless communication module.

[0019] One end of the pressing plate 5 is connected to the driving motor 8 through the rotating shaft 7, and a row of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com