Industrial robot moving platform for explosion-proof environment

A technology for industrial robots and mobile platforms, applied in the field of robots, can solve the problems of reduced cylinder life and vibration of mobile platforms, and achieve the effects of safe driving, stable and accurate working positions, and safe and reliable platforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

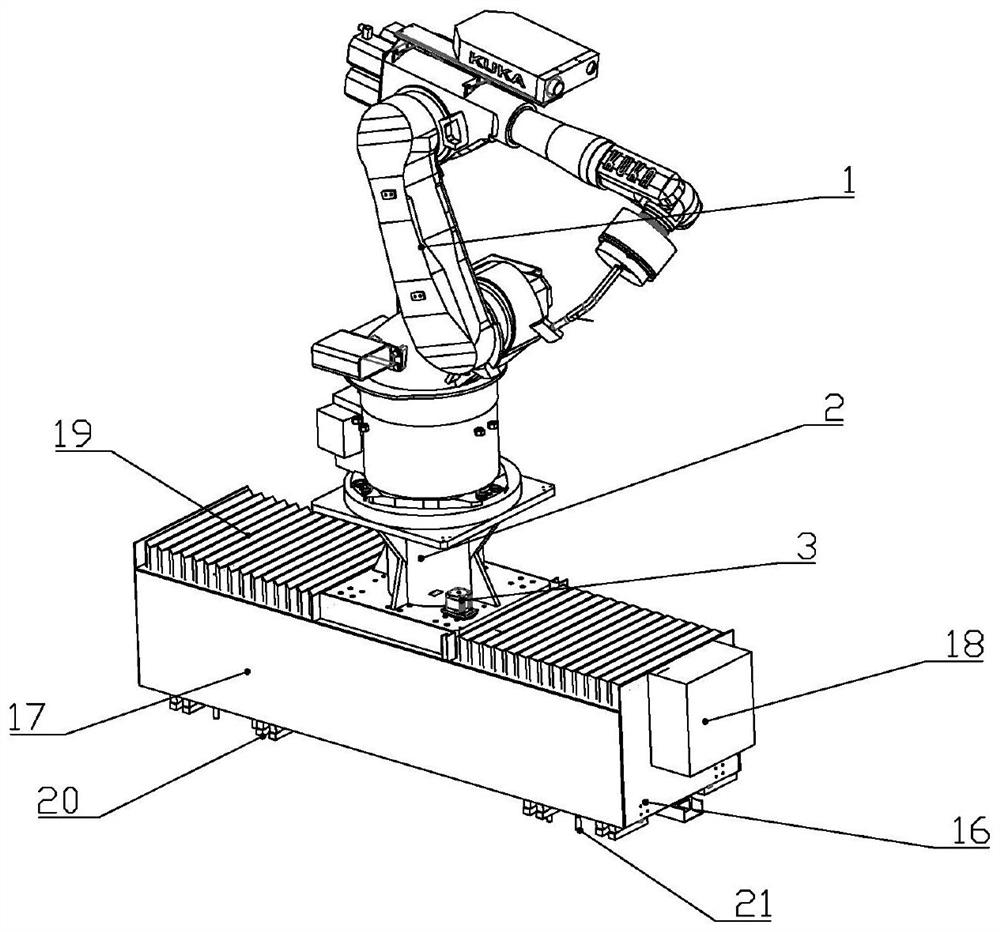

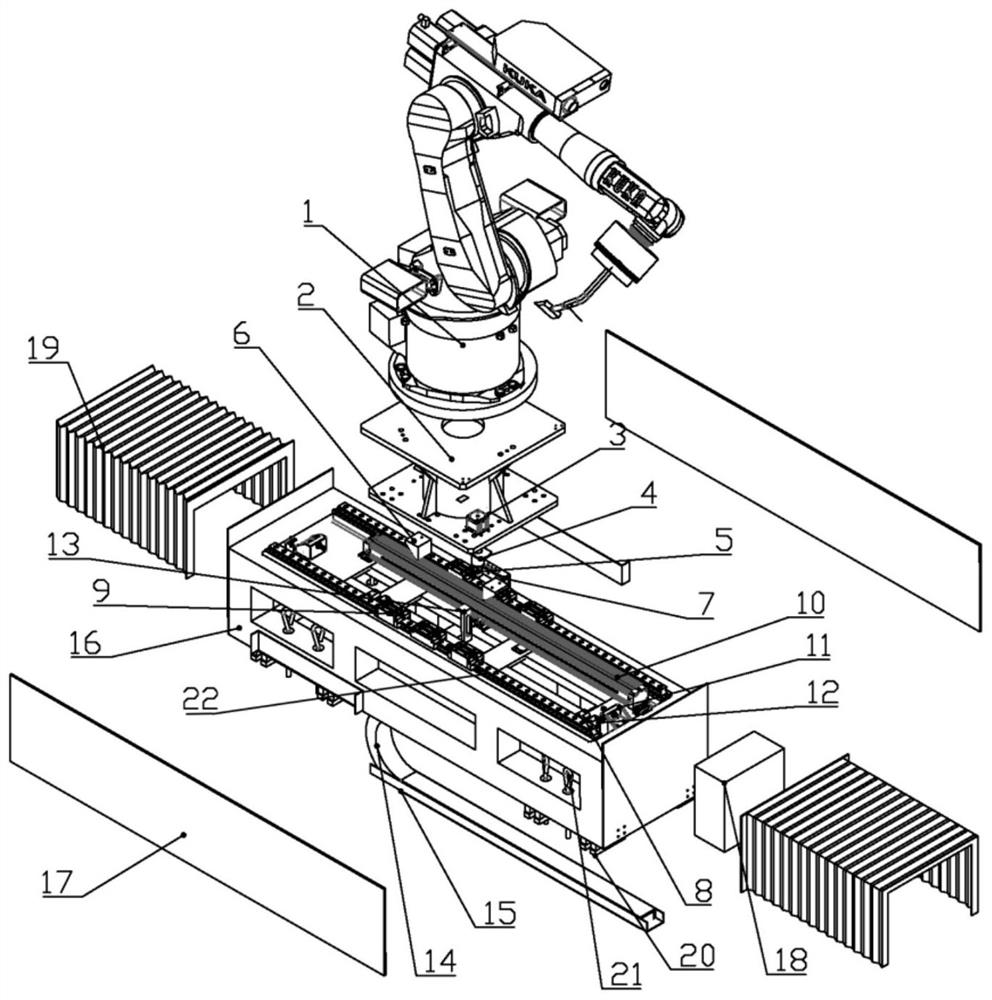

[0036] Such as figure 1 and figure 2 As shown in the figure, an industrial robot mobile platform in an explosion-proof environment includes safety protection components, mobile positioning components, robot mounting base 2 and support components; the walking, positioning and locking of industrial robots are realized through cylinder drive, and the support structure is reasonably structured The design enables industrial robots to work at high positions, and is equipped with safety protection devices to ensure system safety.

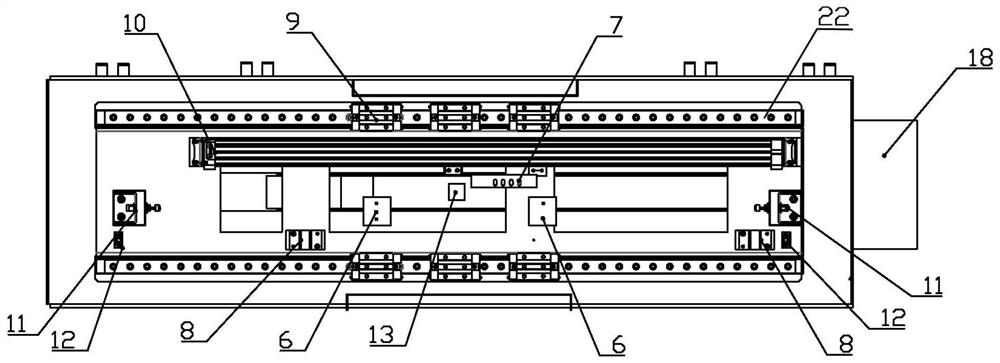

[0037] Such as image 3 As shown, the safety protection assembly includes a steel frame 16, a steel frame protective cover 17, an organ cover 19 and a positive pressure explosion-proof box 18; the steel frame 16 is formed by welding and reinforcing a plurality of square tubes, and is fixed on the On the ground, the steel frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com