Anti-sintering nano AlFx catalyst prepared from porous material precursor containing PO4 tetrahedron, preparation method and application thereof

A porous material and catalyst technology, applied in the field of sintering-resistant nano-AlFx catalyst and its preparation, can solve problems such as catalyst deactivation, and achieve the effects of simple preparation method, high catalytic activity and stability, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using molecular sieve APO-5 as the precursor, put 5.904g of APO-5 into the atmosphere tube furnace, and feed the gaseous fluorine source CHFCl at 300°C 2 , the gas-phase fluorine source flow rate is 10mL / min fluorination for 3h, and then wait until the gas-phase fluorination is completed, the atmosphere in the tube furnace is switched to N 2 Until the temperature is naturally lowered to room temperature, a stable nano-AlFx catalyst is obtained. The prepared nano-AlFx catalyst was characterized by XRD, and calculated by the Scherrer formula, the particle size of the nano-AlFx catalyst was 32.55nm. The obtained catalyst sample is pressed into tablets under 10-20 MPa, crushed, sieved with a 20-40 mesh sieve, and used for the following catalytic reaction.

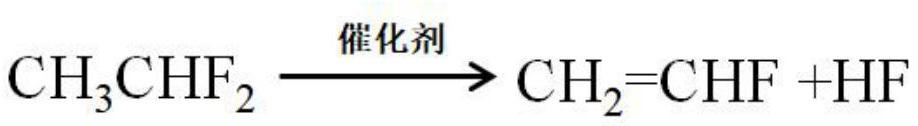

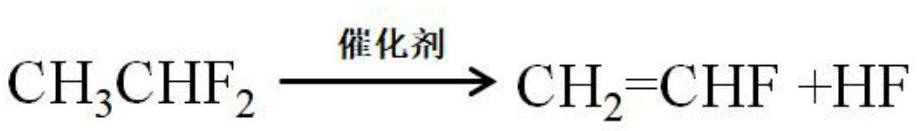

[0022] The nano-AlFx catalyst prepared above is used to catalyze 1,1-difluoroethane (HFC-152a) cracking to prepare vinyl fluoride, and the reaction formula is as follows:

[0023]

[0024] The reaction conditions ar...

Embodiment 2

[0026] Using molecular sieve APO-18 as the precursor, put 6.03g of APO-18 into the atmosphere tube furnace, and feed the gas phase fluorine source CHF at 300°C 3 , the gas-phase fluorine source flow rate is 20mL / min fluorination for 1.5h, and then wait until the gas-phase fluorination is completed, the atmosphere in the tube furnace is switched to N 2Until the temperature is naturally lowered to room temperature, a stable nano-AlFx catalyst is obtained. The prepared nano-AlFx catalyst was characterized by XRD, and calculated by Scherrer's formula, the particle size of the nano-AlFx catalyst was 33.10nm. The obtained catalyst sample is pressed into tablets under 10-20 MPa, crushed, sieved with a 20-40 mesh sieve, and used for the following catalytic reaction.

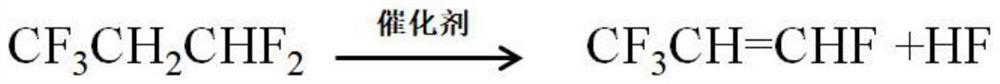

[0027] The nano-AlFx catalyst prepared above is used to catalyze the cracking of 1,1,1,3,3-pentafluoropropane (HFC-245fa) to prepare 1,3,3,3-tetrafluoropropene (HFO-1234ze), the reaction formula as follows:

[0028] ...

Embodiment 3

[0031] Using molecular sieve SAPO-5 as the precursor, put 7.43g of SAPO-5 into the atmosphere tube furnace, and feed the gas phase fluorine source CHF at 300°C 3 , the gas-phase fluorine source flow rate is 10mL / min fluorination for 3h, and then wait until the gas-phase fluorination is completed, the atmosphere in the tube furnace is switched to N 2 Until the temperature is naturally lowered to room temperature, a stable nano-AlFx catalyst is obtained. The prepared nano-AlFx catalyst was characterized by XRD, and calculated by the Scherrer formula, the particle size of the nano-AlFx catalyst was 33.09nm. The obtained catalyst sample is pressed into tablets under 10-20 MPa, crushed, sieved with a 20-40 mesh sieve, and used for the following catalytic reaction.

[0032] The nano-AlFx catalyst prepared above is used to catalyze the cracking of 1,1-difluoroethane (HFC-152a) to prepare vinyl fluoride, and the reaction formula is as follows:

[0033]

[0034] The reaction condi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com