Shell, preparation method thereof and electronic equipment

A shell and body technology, applied in the field of electronics, can solve the problem of insufficient appearance expression, and achieve the effects of strong designability, good appearance expression and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] See Figure 5 , the embodiment of the present application also provides a method for preparing the casing 100, which includes:

[0088] S201, providing the housing body 10;

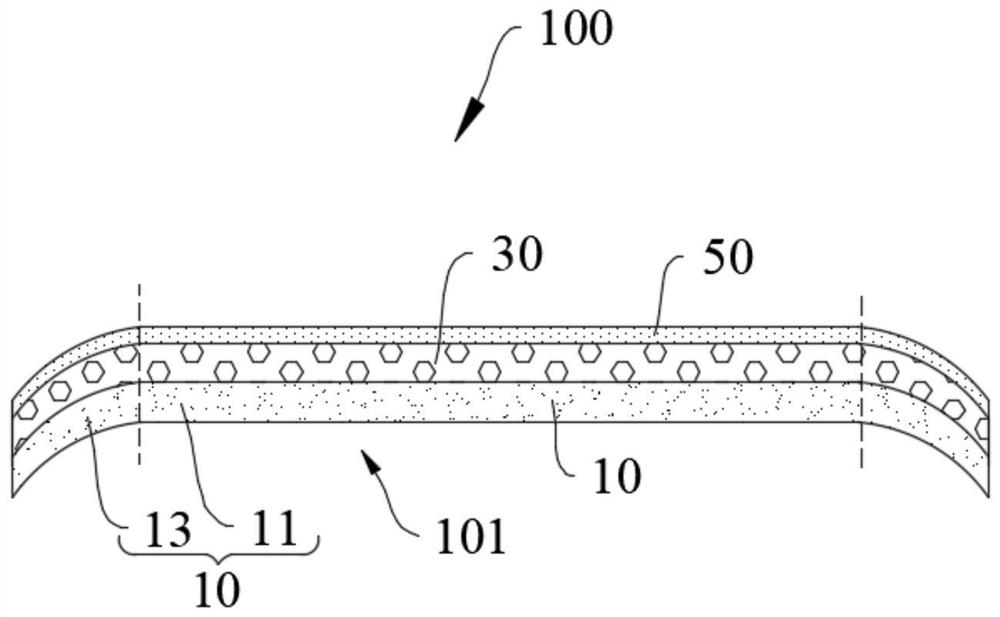

[0089] Optionally, the housing body 10 can be a transparent substrate or an opaque substrate. Optionally, the housing body 10 can be a transparent substrate 10 or an opaque substrate 10 . The transparent substrate can be but not limited to polycarbonate (Polycarbonate, PC) substrate, polyethylene terephthalate (Polyethylene terephthalate, PET) substrate, PC / PMMA composite board, PET / PMMA composite board, PC / PET composite board, PC / PET / PMMA composite board, etc. For the parts that are the same as those in the foregoing embodiments, please refer to the description of the corresponding parts in the foregoing embodiments, and details are not repeated here.

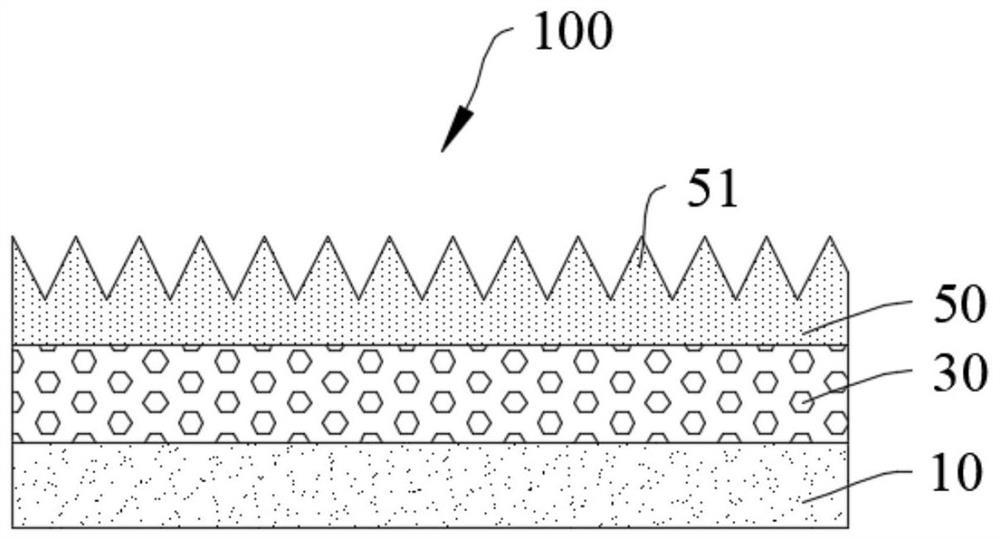

[0090] S202, forming a hardened layer 30 on the surface of the housing body 10;

[0091] Optionally, mix the raw material components of the h...

Embodiment 1、 Embodiment 2 and comparative example 1

[0149] The shells 100 of the present embodiment and the comparative example are prepared by the following steps (the following fractions are all weight fractions):

[0150] 1) Provide a housing body 10, the housing body 10 is a PC / PMMA composite board, and the thickness of the composite board is 0.64mm, wherein the thickness of the PC layer is 0.59mm, and the thickness of the PMMA layer is 0.05mm;

[0151] 2) Apply a hardening liquid on the PMMA surface of the shell body 10 and bake at 70° C. for 5 minutes to form a hardened adhesive layer; wherein, the hardening liquid in Example 1 includes 35% urethane acrylate, 2.5% TPO and acetic acid ethyl ester; the curing liquid of Example 2 includes 35% urethane acrylate, 7% epoxy acrylate, 2.5% TPO and ethyl acetate; the curing liquid of Comparative Example 1 includes 35% urethane acrylate, 14% epoxy acrylic acid Ester, 2.5% TPO and ethyl acetate;

[0152] 3) When the curing energy is 200mj / cm 2 up to 1000mj / cm 2 Under the mercury ...

Embodiment 3 to Embodiment 5、 comparative example 2 to comparative example 4

[0155] The shells 100 of the present embodiment and the comparative example are prepared by the following steps (the following fractions are all weight fractions):

[0156] 1) Provide a housing body 10, the housing body 10 is a PC / PMMA composite board, and the thickness of the composite board is 0.64mm, wherein the thickness of the PC layer is 0.59mm, and the thickness of the PMMA layer is 0.05mm;

[0157] 2) Apply a hardening liquid on the PMMA surface of the shell body 10 and bake it at 70°C for 5 minutes to form a hardened adhesive layer; wherein, the hardening liquid includes 35% urethane acrylate, 7% epoxy acrylate, 2.5% TPO and ethyl acetate;

[0158] 3) When the curing energy is 200mj / cm 2 up to 1000mj / cm 2 Under the mercury lamp, the hardened adhesive layer is cured to form a hardened layer 30;

[0159] 4) Using ink to print an ink glue layer on the surface of the hardened layer 30 away from the housing body 10 ; wherein, the total weight of the urethane acrylate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com