High-performance composite rubber floor and processing technology thereof

A composite rubber and processing technology, which is applied in the field of rubber flooring, can solve problems such as easy wear, impact on rubber floor performance, and difficulty in cleaning, and achieve the effects of not being easily deformed and broken, reducing the amount of cutting residue, and ensuring beautiful flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

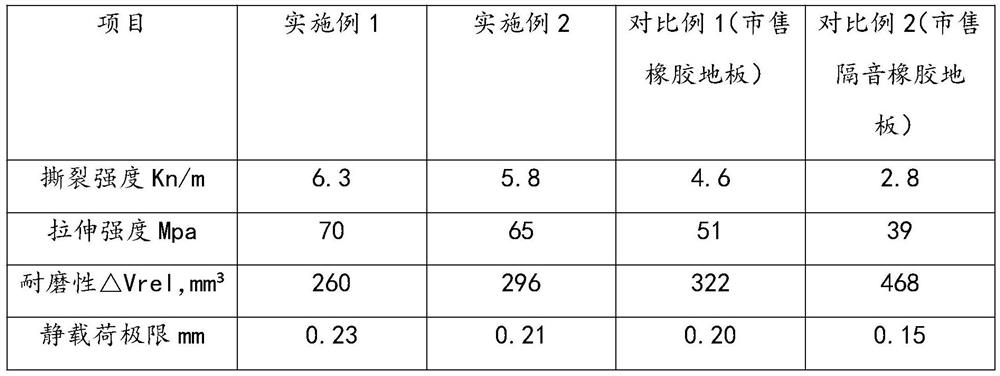

Embodiment 1

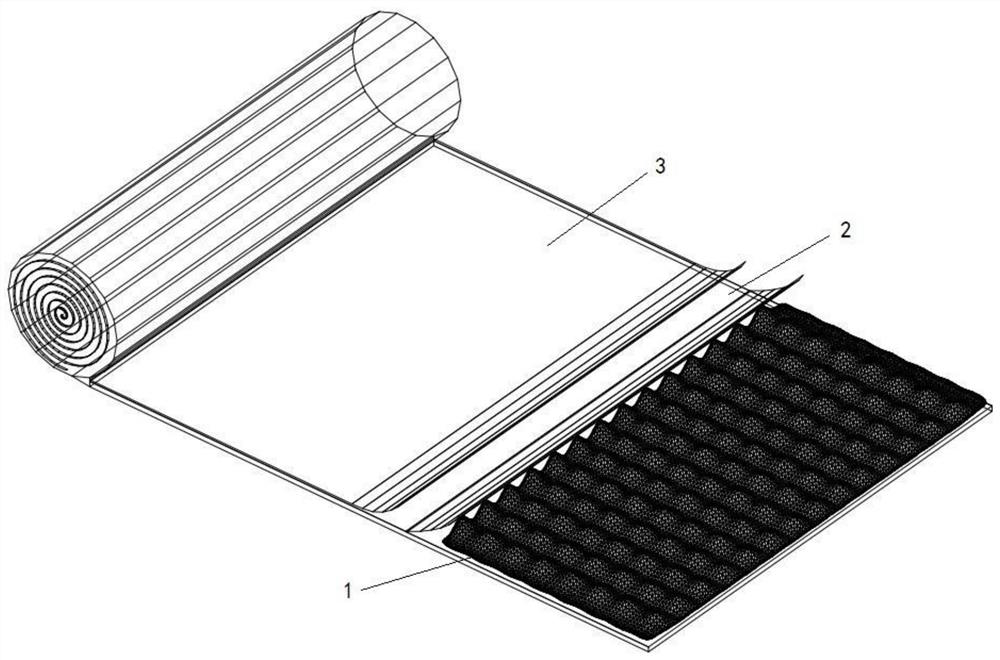

[0053] A process for producing high-performance composite rubber floor steps of:

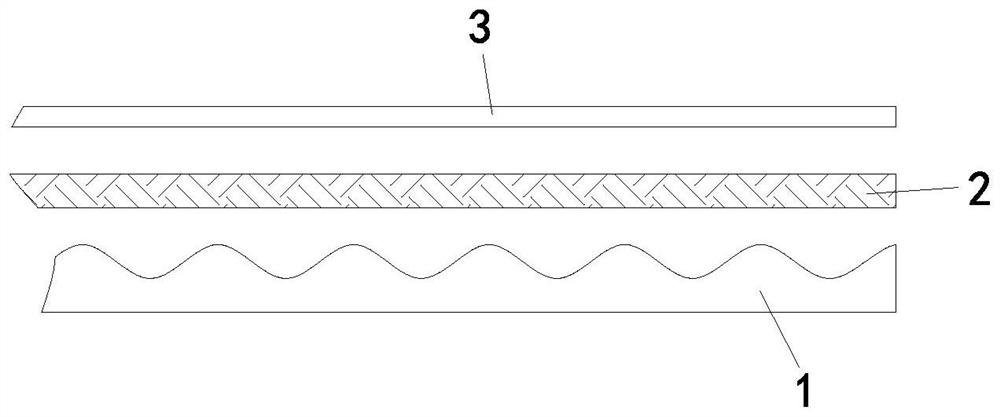

[0054] 1, making up the elastic layer is 1: A SBR adhesive rubber particles uniformly mixed and poured into a mold, preformed egg tray type, to give an elastic layer (having a thickness of 5mm);

[0055] 2, the reinforcing layer 2 made of: silicon PU preformed sheet type, the reinforcing layer to obtain 2 (thickness 2mm);

[0056] 3, the reinforcing layer can be colored 2: according to customer needs, on the reinforcing layer 2 forming a printed pattern;

[0057] 4, pretreatment of the reinforcing layer 2: reinforcing rubber coating layer 2 and lower surfaces activator (titanate coupling agent GR330), through heat curing in hot air, a temperature of 88 deg.] C, time 8min;

[0058] 5, post-processing and production of abrasion resistant layer 3: 2 in the preprocessed front reinforcing layer coating liquid rubber (rubber accounting for milk 10 to 12%, accounting for 3% of liquid silicone rubber and po...

Embodiment 2

[0066] A process for producing high-performance composite rubber flooring is as follows:

[0067] 1, the elastomeric layer 1: the foam rubber particles, cork particles and an adhesive poured into a mold after mixing uniformly, a preformed egg tray type, to give an elastic layer (thickness 8mm);

[0068] 2, the reinforcing layer 2 made of: silicon PU preformed sheet type, the reinforcing layer to obtain 2 (thickness of 0.8mm);

[0069] 3, the reinforcing layer can be colored 2: according to customer needs, on the reinforcing layer 2 forming a printed pattern;

[0070] 4, pretreatment of the reinforcing layer 2: reinforcing rubber coating layer 2 and lower surfaces activator (titanate coupling agent GR330), through heat curing in hot air, a temperature of 85 ℃, time 6min;

[0071] 5, post-processing and production of abrasion resistant layer 3: 2 in the preprocessed front reinforcing layer coating liquid rubber (rubber accounting for milk 10 to 12%, accounting for 3% of liquid silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com