Processing detection system and manufacturing method of off-axis aspheric element

An off-axis aspheric surface and detection system technology is applied in the field of processing and testing systems for off-axis aspheric components, and can solve problems affecting the processing and detection efficiency of large-diameter off-axis aspheric components, affecting off-axis parameter control accuracy and detection efficiency, and non- Due to the large weight of spherical components, the effect of reducing the time of repeated clamping and alignment, improving the processing accuracy and processing efficiency, and improving the clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

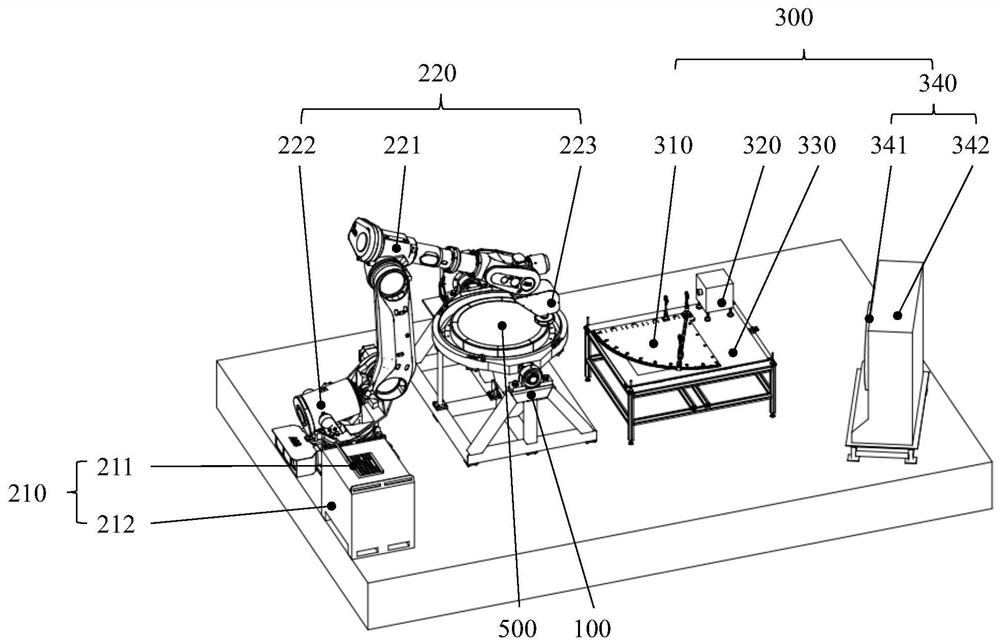

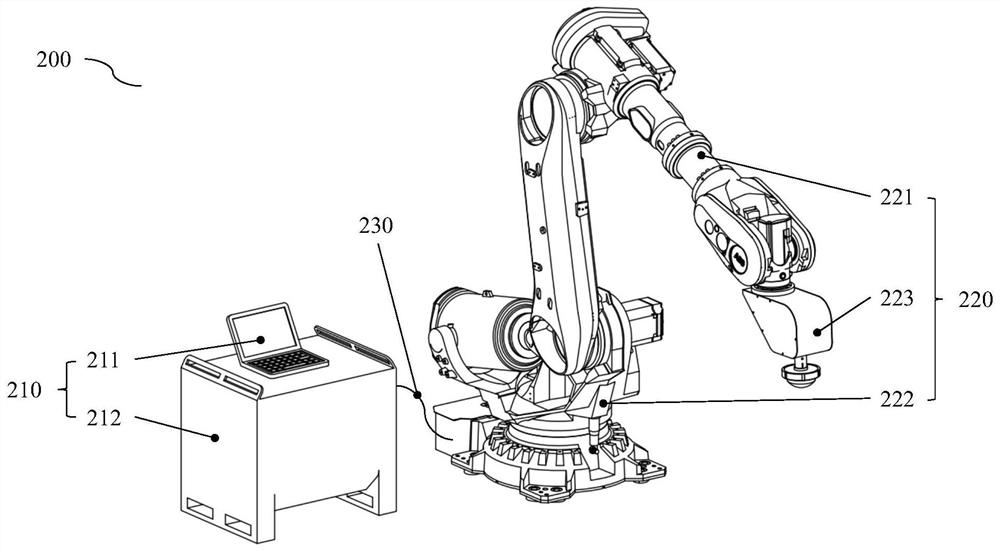

[0050] Such as figure 1 , figure 2 As shown, Embodiment 1 of the present invention provides a processing and detection system for off-axis aspheric components, including a turning device 100, a processing device 200 and a detection device 300:

[0051] The inversion device 100 is located between the processing device 200 and the detection device 300, and the inversion axis of the inversion device 100 intersects the output optical path of the detection device 300;

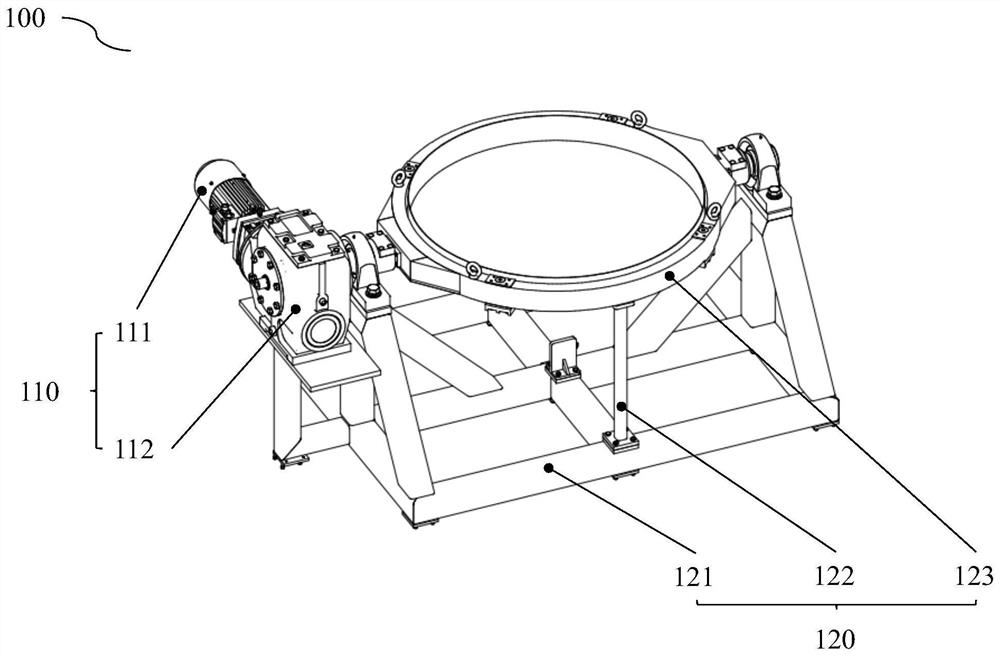

[0052] The turning device 100 includes a driving mechanism 110 and a supporting mechanism 120 , and the driving mechanism 110 is connected with the supporting mechanism 120 .

[0053] By setting the turning device 100 between the processing device 200 and the detection device 300, and realizing the support of the off-axis aspheric element 500 through the support mechanism 120 on the turning device 100, the off-axis aspheric element 500 is supported through the driving mechanism 110 on the turning device 100. The ...

Embodiment 2

[0073] Embodiment 2 of the present invention provides a method for manufacturing an off-axis aspheric element, including the following steps:

[0074] Step S10: setting up the processing and detection system of the off-axis aspheric element, processing the off-axis aspheric element 500, and detecting the off-axis aspheric element 500;

[0075] Step S20: If the surface shape error of the off-axis aspheric element 500 is not less than the preset error threshold, control the support mechanism 120 to be at the processing position through the driving mechanism 110, and continue to step S10; if the surface shape error of the off-axis aspheric element 500 is If the error is smaller than the preset error threshold, the desired off-axis aspheric element is obtained.

[0076] By judging whether the surface shape error of the off-axis aspheric element 500 is less than the preset error threshold, it is determined whether to continue processing and testing until the surface shape error of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com