Clamping and pressing connector

A technology for crimping joints and connecting parts, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, non-detachable pipe connections, etc. It can solve the problems of insufficient reliability in use, achieve reliability, improve reliability, and reduce stamping The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

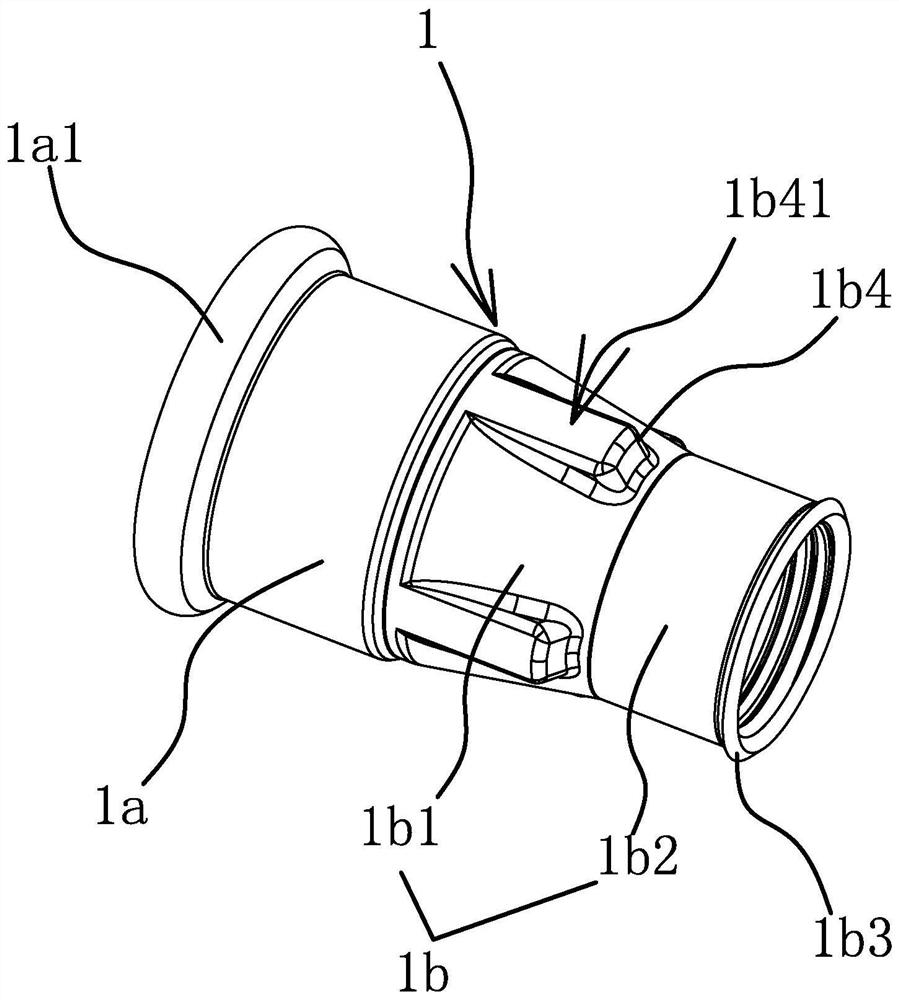

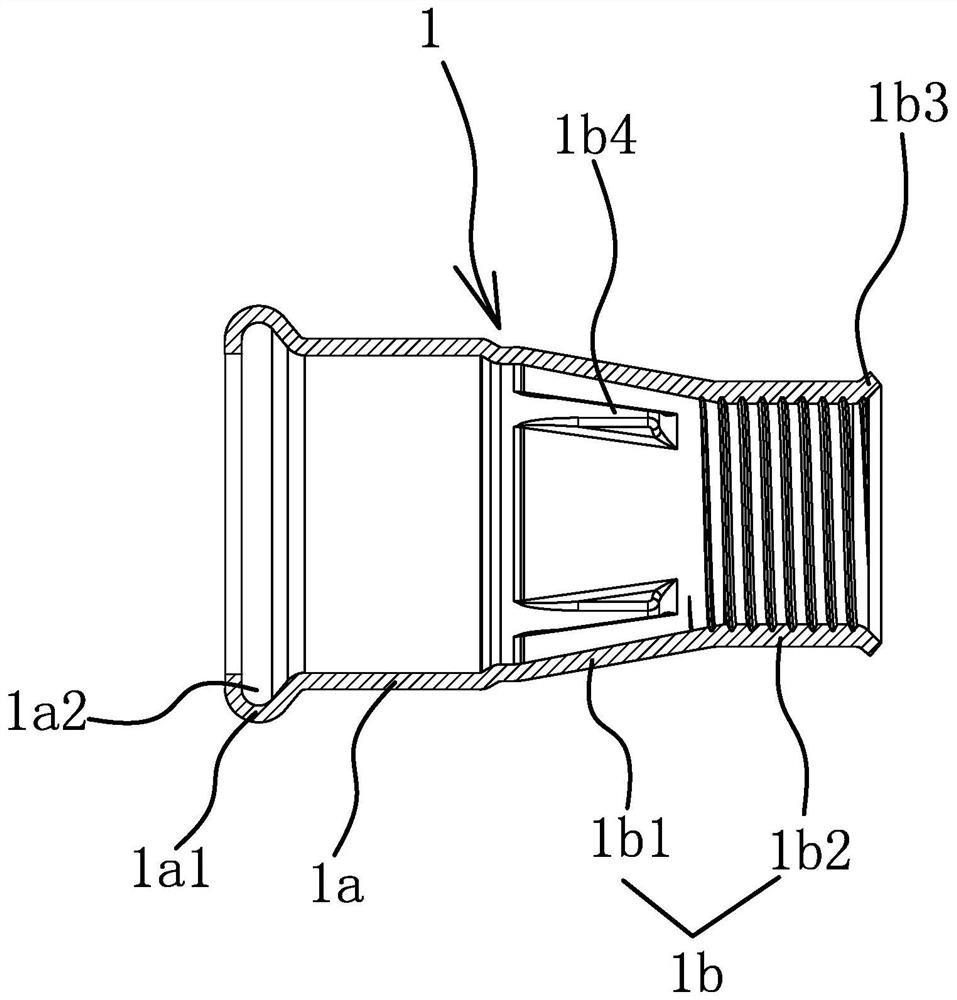

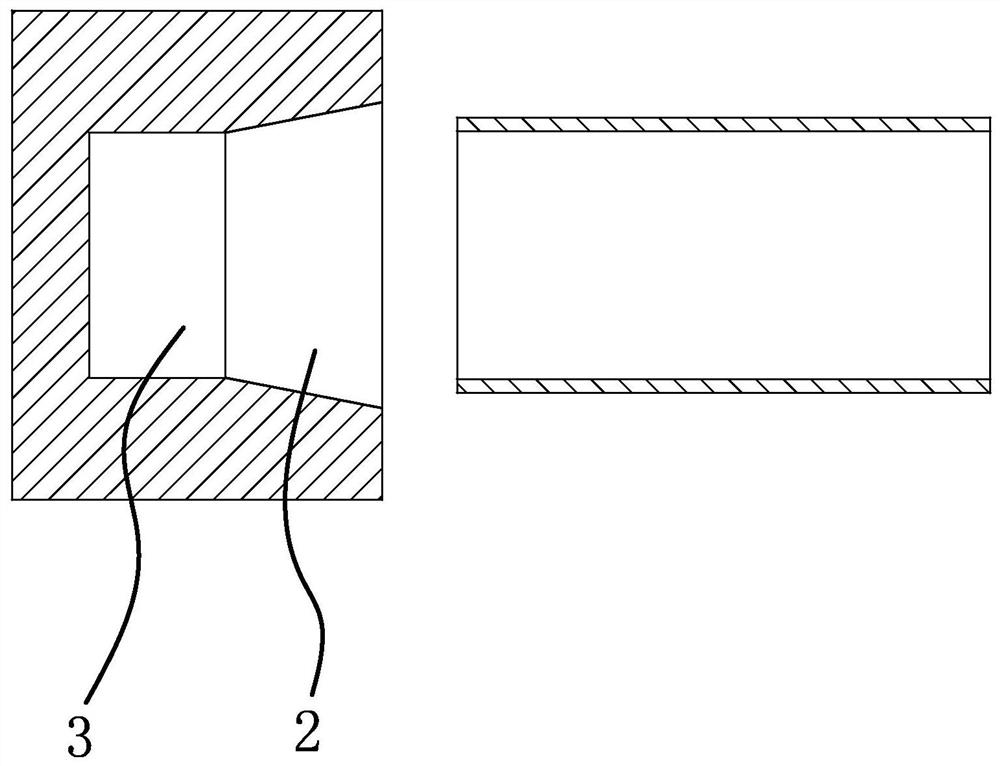

[0028] like figure 1 and figure 2 As shown, the crimping joint includes a straight-through joint body 1 made of pipe material (specifically, carbon steel pipe). The connecting section 1b of the connecting section 1a has a protruding ring 1a1 at the end of the crimping section 1a, and a groove 1a2 is provided on the inner side of the crimping section 1a corresponding to the position of the protruding ring 1a1, and the groove 1a2 is used to place a sealing ring. Insert the thin-walled stainless steel pipe to be connected into the crimping section 1a, the sealing ring and the outer wall of the thin-walled stainless steel tube are pressed against to form a seal, and then clamped on the outside of the crimping section 1a with a crimping tool, so that the crimping section 1a and The thin-walled stainless steel tubes are simultaneously deformed inwards to hold them together. Further, the connecting section 1b includes a transition part 1b1 and a connecting part 1b2 sequentially al...

Embodiment 2

[0034] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the end of the connecting portion 1b2 is a constricted portion that shrinks inward to form a tapered portion, and the thread is arranged on the outside of the connecting portion 1b2 That is the external thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com