Goaf deep pile forming device

A goaf and pile-forming technology, applied in mining equipment, shaft equipment, earthwork drilling, etc., can solve the problems of difficulty in engineering construction, waste of a lot of materials, delay in construction period, etc., to achieve short construction work cycle, avoid slurry waste, less damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

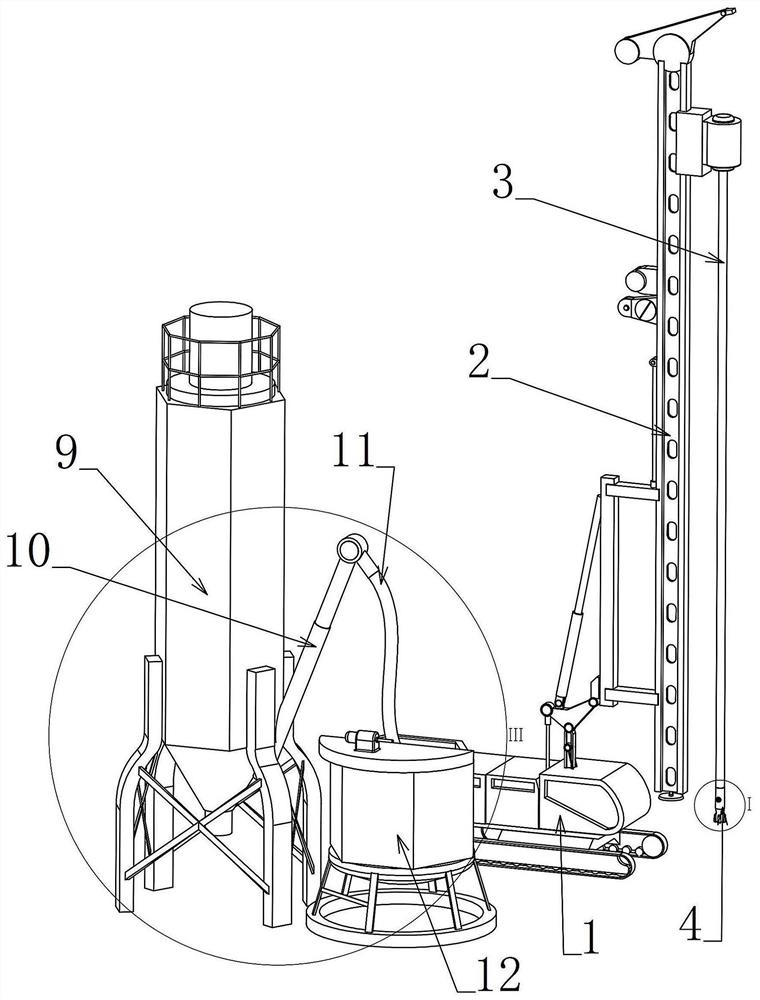

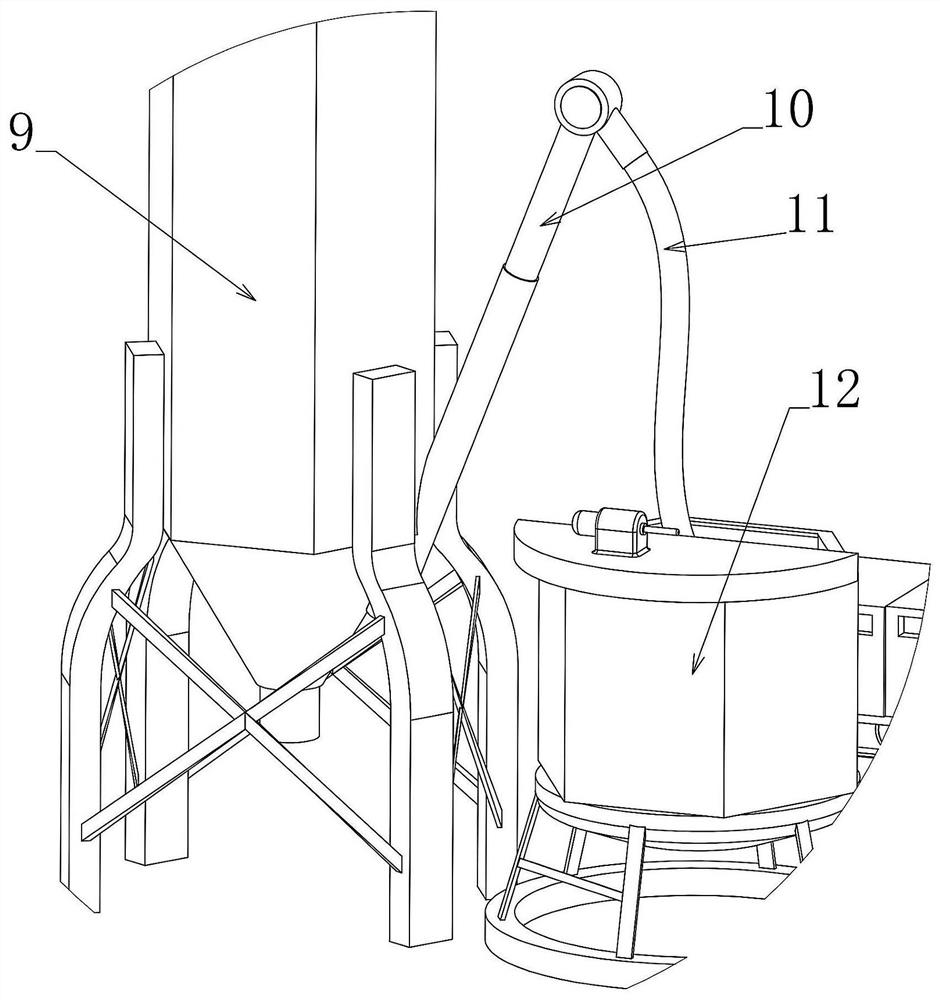

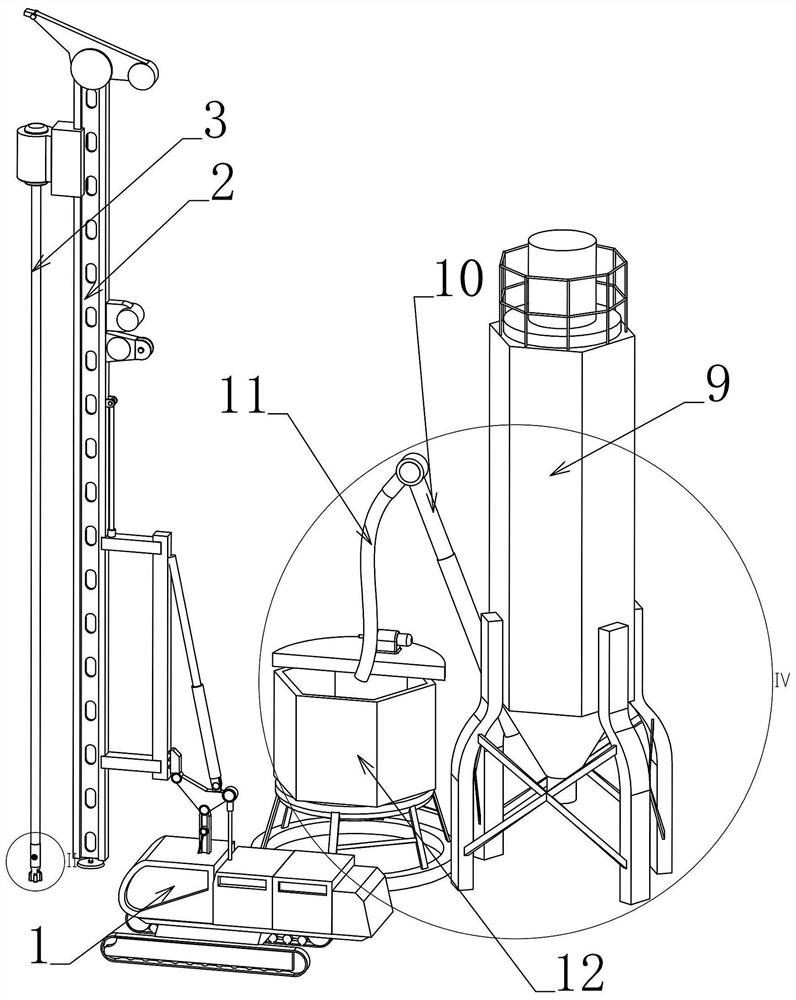

[0025] The following is attached Figure 1-6 The specific implementation manners of the present invention are further described in detail.

[0026] When this embodiment is in use, the required materials are first prepared in the pressure feeder, and the various components in the pressure feeder work together to store the required materials in the stocker, and the stocker When various materials are used, the set ratio of materials is transported to the mixing device 12, and the various materials are uniformly mixed in the mixing device 12. The mixed materials need to meet the following conditions and can be carried out in the underground space. Solidification, after solidification, the required strength can be achieved, and solidification can be carried out in an oxygen-free environment, and then the mixed materials are placed in the mixing device 12 until used, and at the same time, the carrier vehicle 1 is driven to the designated place, and the upper end of the carrier vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com