Overwater landscape plank road combining prefabricated square piles and cast-in-place concrete members

A technology of concrete and prefabricated squares, applied to roads, roads, sheet pile walls, etc., can solve the problems of high temporary cost of construction measures, easy damage to the water environment, and difficulty in guaranteeing construction quality, so as to improve economic benefits and time benefits, which is important Engineering practicability and safety, and the effect of reducing the cost of temporary construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

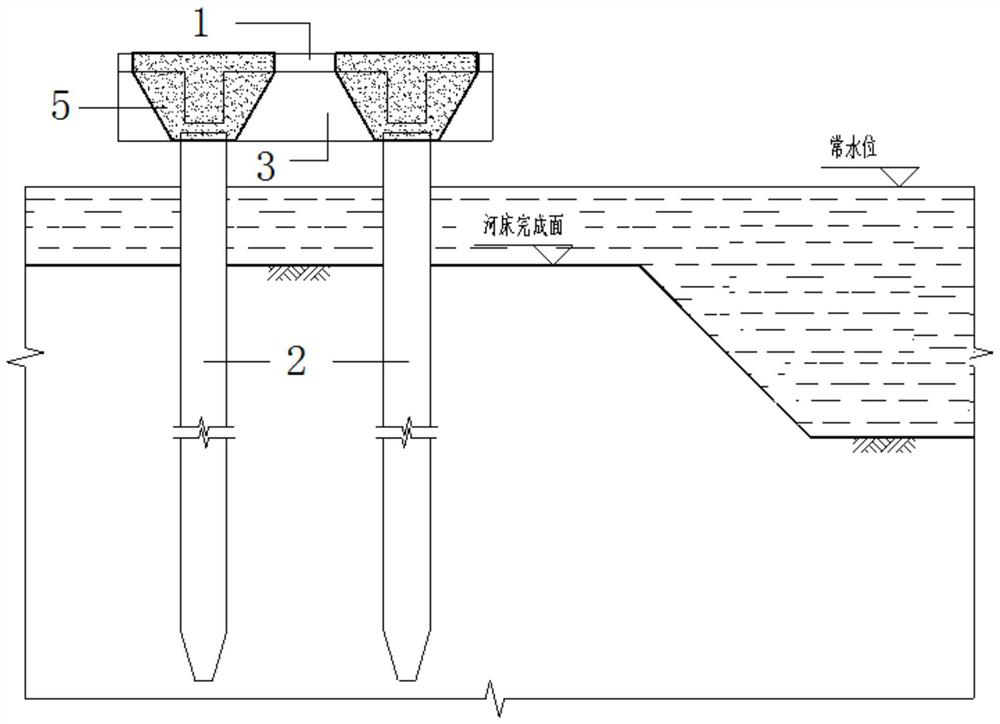

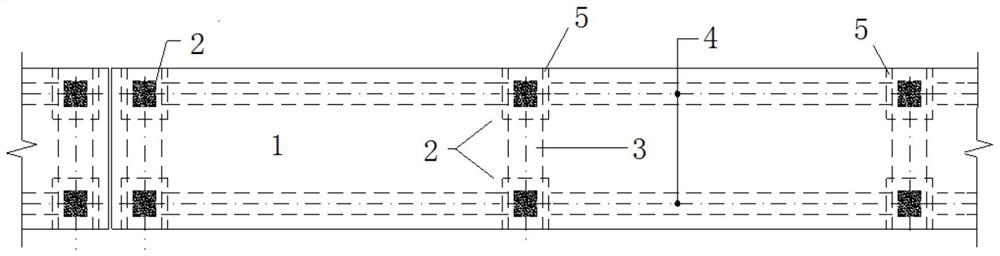

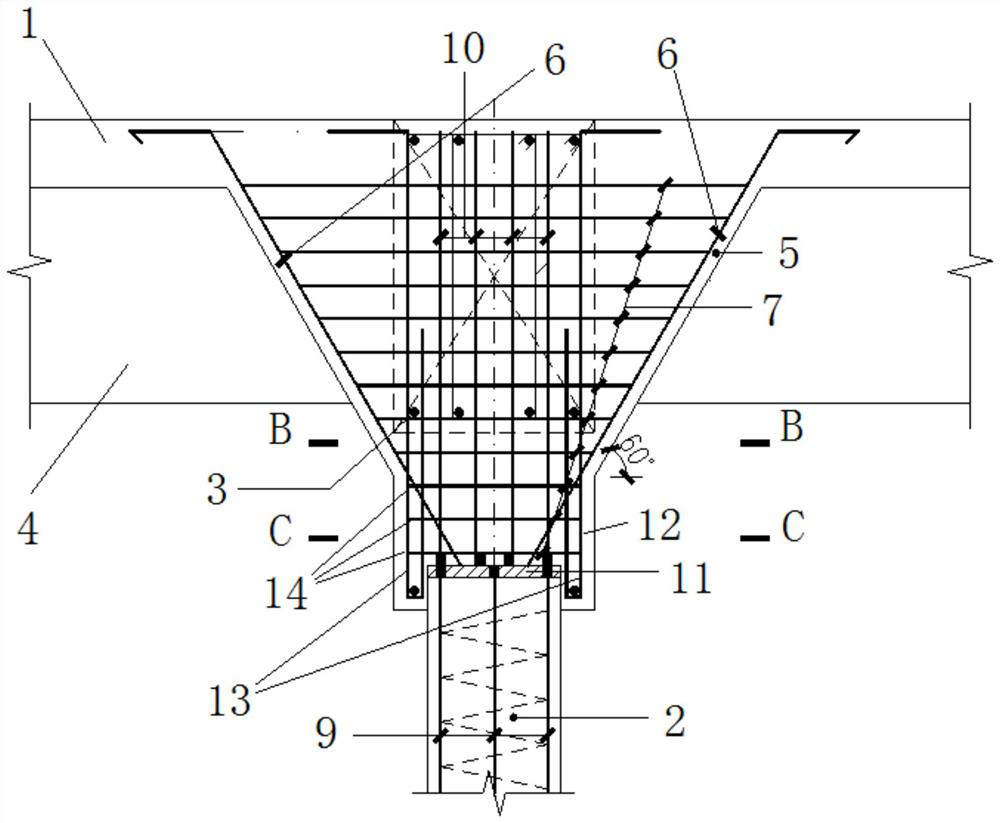

[0054] Such as Figure 1 to Figure 5 As shown, the water landscape plank road combined with prefabricated square piles and cast-in-place concrete components includes a plank road platform whose elevation is above the water surface; it is characterized in that the plank road platform includes several cast-in-place concrete beams and slabs 1; All are provided with several prefabricated square piles 2, and are fixed with the underwater foundation through several prefabricated square piles 2;

[0055] Each cast-in-place concrete beam slab 1 is provided with a plurality of short concrete cast-in-place beams 3 uniformly distributed along the length direction and more than two long concrete cast-in-place beams 4 uniformly distributed along the width direction as frame beams;

[0056] Every short concrete cast-in-place beam 3 and the frame-beam crossing position of any corresponding long concrete cast-in-place beam 4 intersect are all fixed by the upper end of pile cap 5 and prefabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com