Preparation method of iron tailing reinforced rubber functional filler

A technology of functional filler and reinforced rubber, which is applied in the field of comprehensive utilization of solid waste and the preparation of new composite materials, and can solve problems such as lack of technical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

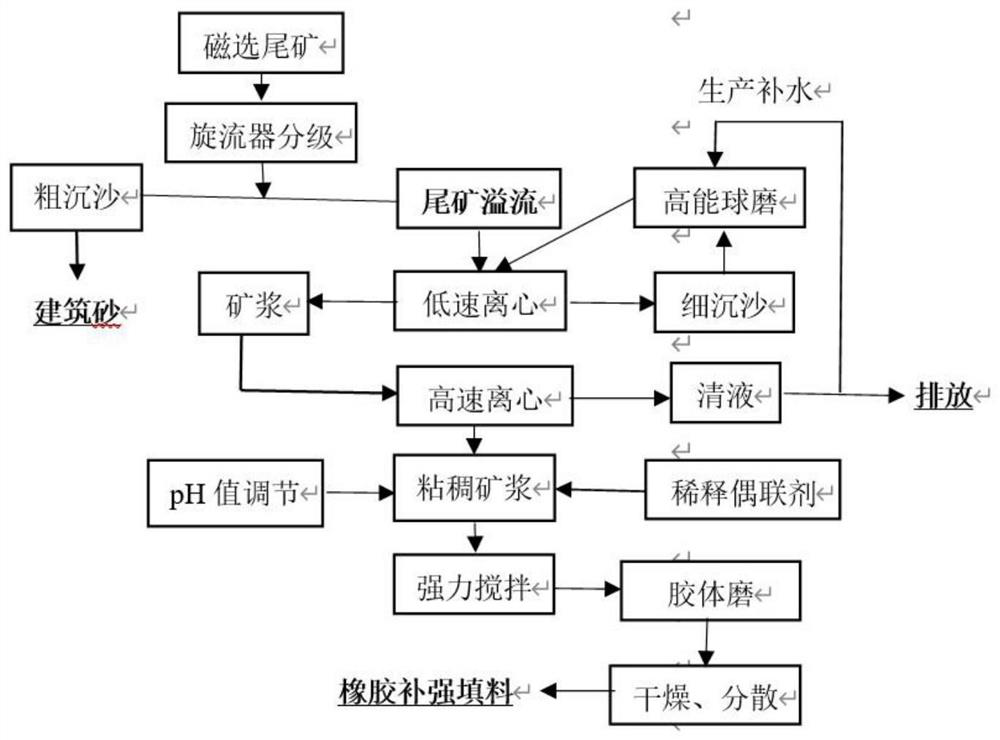

Method used

Image

Examples

Embodiment 1

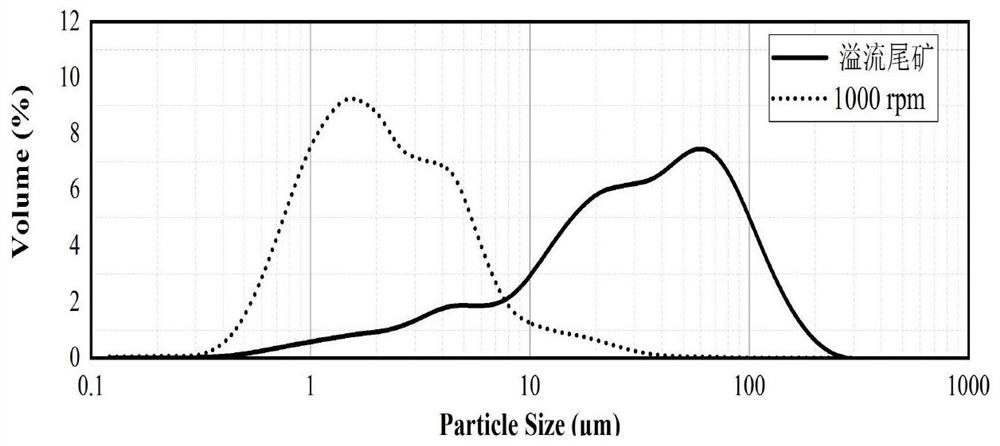

[0032] The fine-grained iron tailings slurry overflowing from the cyclone classification of the mine concentrator is sent to a 1000rpm low-speed centrifuge for separation, and the ultra-fine iron tailings suspension slurry with a particle size of less than 5 microns is obtained from the discharge port, and the fine-grained iron tailings slurry is obtained from the sand discharge port. Particles with a diameter greater than 5 microns (that is, grit); the grit is added to the planetary high-energy ball mill, and the grinding speed is 1000rpm, the material-to-ball ratio is 1:4, and the solid-liquid ratio is 1:4, and the grinding is carried out for 240 minutes. into a low-speed centrifuge, and sorted again at a speed of 1000rpm to obtain ultra-fine iron tailings suspension slurry with a particle size of less than 5 microns and particles with a particle size greater than 5 microns (the particles are partially discarded or continue high-energy ball milling); the slurry Partially use ...

Embodiment 2

[0036] The overflow from the cyclone classification of the mine concentrator is sent to a 400rpm centrifuge for separation, and the sand is added to a planetary high-energy ball mill. Under the conditions of a rotation speed of 1500rpm, a material-to-ball ratio of 1:4, and a solid-to-liquid ratio of 1:4, it is ground for 30 minutes. After ball milling The ore pulp is sent to the low-speed centrifuge again, and is sorted again at a speed of 400rpm. The pulp part is dehydrated at a high speed by a horizontal centrifuge at a speed of 2800rpm. 0.1M NaOH to adjust the pH value to 7.5, add KH-570 diluted with 10 times of industrial ethanol, the amount of KH-570 added is 1% of the mass of solid particles in the thick ore slime, stir at 800rpm for 30min, and introduce into the plane shear after the combination of rotor and stator A high-shear colloid mill with a crushing distance of 0.05 mm and a rotor speed of 2900 rpm, and finally disperse for 30 minutes. Then dry at 105°C, disperse...

Embodiment 3

[0039] The overflow from the cyclone classification of the mine concentrator is sent to the 800rpm centrifuge for separation, and the sand is added to the planetary high-energy ball mill. At the speed of 1200rpm, the ratio of material to ball is 1:4, and the ratio of solid to liquid is 1:4. Grinding for 60 minutes, after ball milling The ore pulp is sent to the low-speed centrifuge again, and is sorted again at a speed of 800rpm. The pulp part is dehydrated at a high speed by a horizontal centrifuge at a speed of 2500rpm. 0.1MH 2 SO 4 Adjust the pH value to 6.5, add titanate diluted with 5 times industrial ethanol, the amount of titanate added is 2.5% of the mass of solid particles in the thick ore slime, stir at 700rpm for 60min, and then import into the plane shear crushing after the combination of rotor and stator A high-shear colloid mill with a distance of 0.10mm and a rotor speed of 2900rpm, and finally disperse for 30min. Then dry at 105°C, disperse in a 500rpm ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com