Anionic Zn (II)-MOF for one-step purification of ethylene

An anionic and ionic technology, applied in the direction of adsorption purification/separation, organic chemistry, other chemical processes, etc., can solve cumbersome problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Mix the organic ligand (0.025mmol ATZ and 0.0125mmol iPA-OH) and zinc nitrate hexahydrate (0.03mmol) in 4.0mL of N,N-dimethylformamide, add 0.14mL of tetrafluoroboric acid, seal in a vial middle. Crystals of the metal-organic framework were obtained via thermal reaction at 135° C. for 72 hours.

Embodiment 2

[0023] Mix the organic ligand (0.025mmol ATZ and 0.0125mmol iPA-OH) with anhydrous zinc acetate (0.03mmol) in 4.0mL of N,N-dimethylformamide, add 0.12mL of tetrafluoroboric acid, seal in a vial middle. Crystals of the metal-organic framework were obtained via thermal reaction at 150° C. for 48 hours.

[0024] The test result of the product of above-mentioned embodiment gained is identical, specifically sees following:

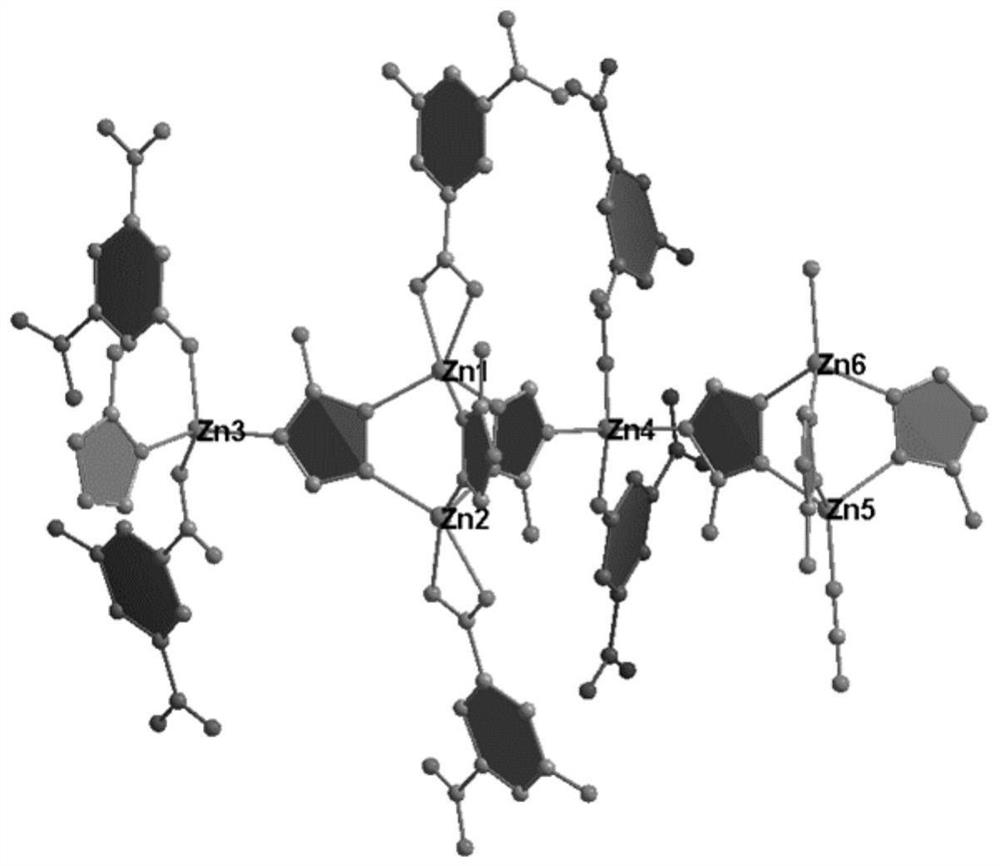

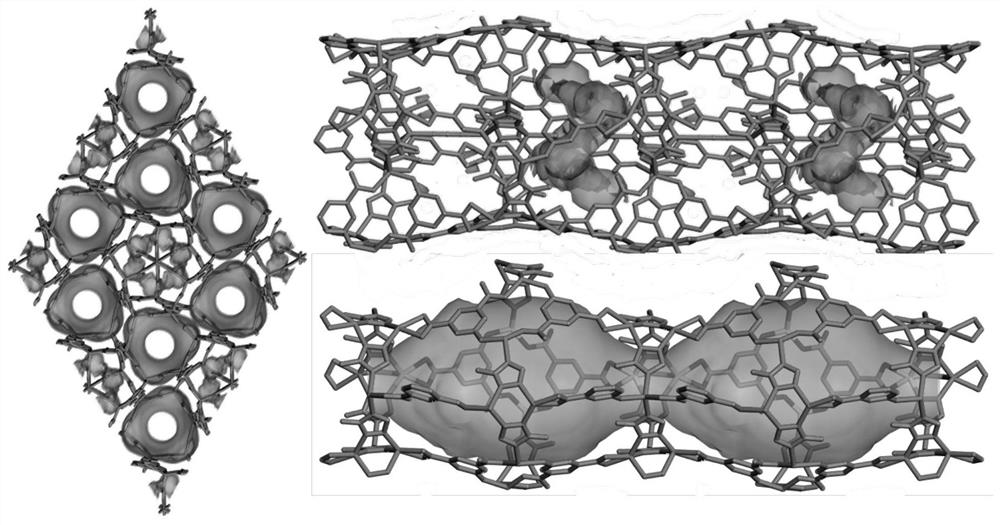

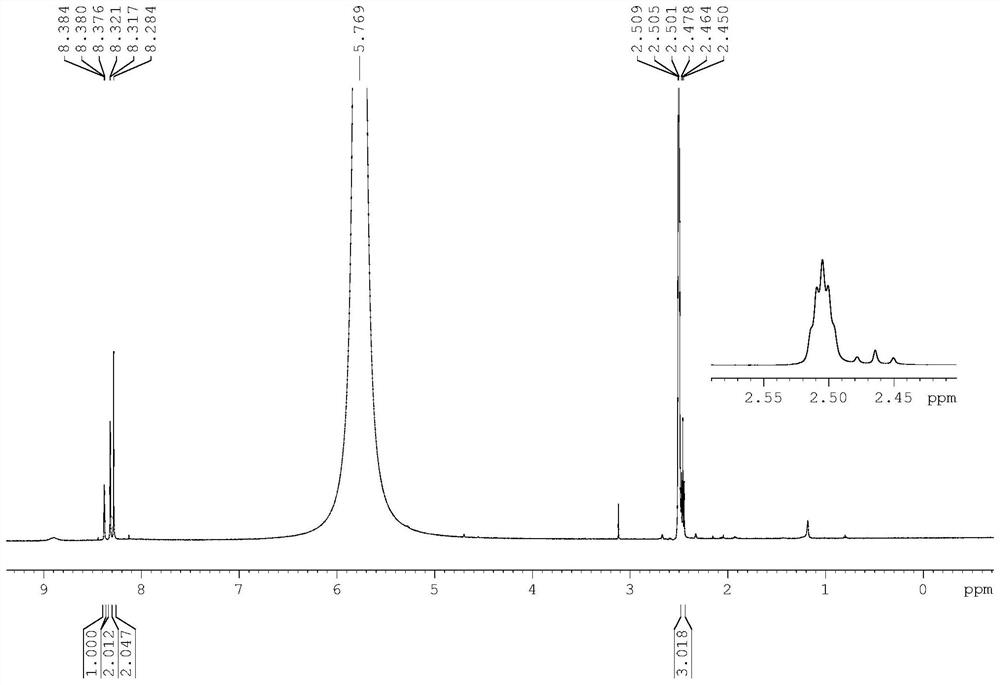

[0025] (1) Determination of crystal structure:

[0026] Select crystals with regular shape, smooth surface and appropriate size, and use graphite monochromatic enhanced Cu-Kα radiation source at room temperature The crystal data were collected on a Rigaku Supernova CCD diffractometer, and then the crystal structure was analyzed and refined. See the structure diagram Figure 1 to Figure 2 . The crystallographic data are listed in Table 1.

[0027] Table 1 Crystallographic data of MOFs

[0028]

[0029]

[0030] figure 1 The structure diagram shows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com