Preparation of high-salt-resistant self-elasticity-increasing type hydrophobic association polymer and application of high-salt-resistant self-elasticity-increasing type hydrophobic association polymer in fracturing fluid

A hydrophobic association and polymer technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low viscosity retention rate and large viscosity reduction, and achieve convenient operation, increased elasticity and high solution cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

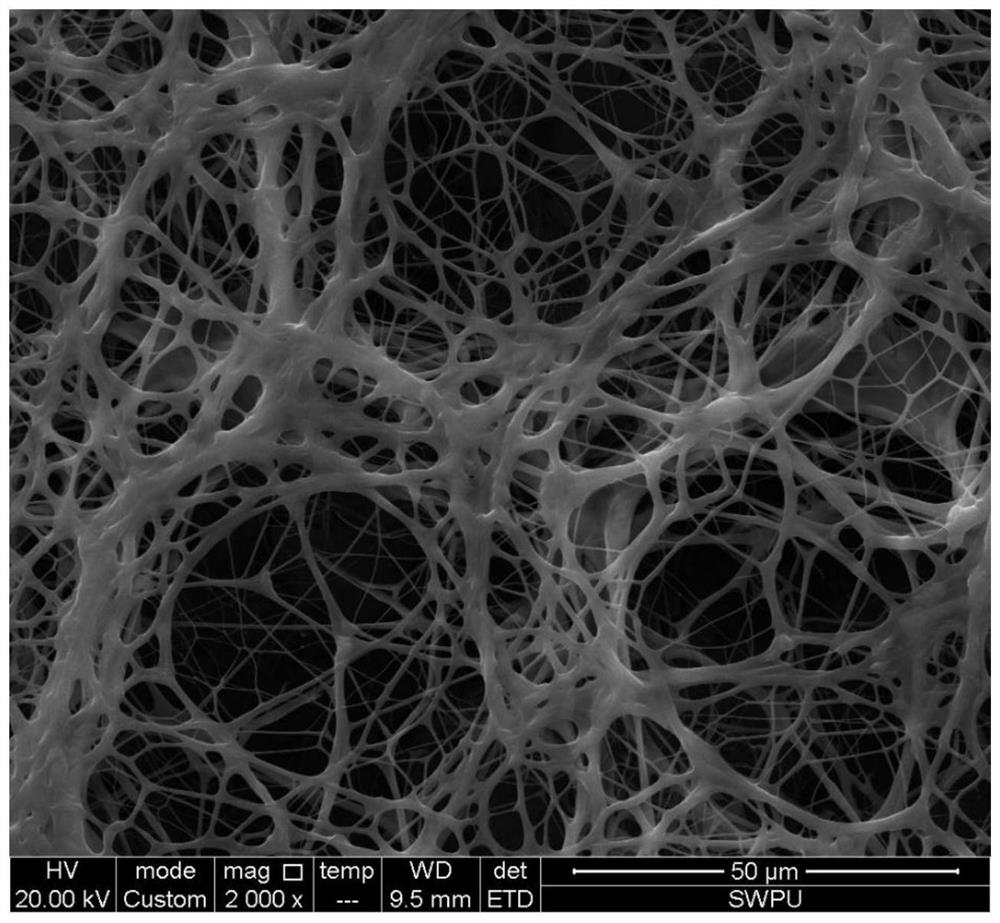

Image

Examples

Embodiment 1

[0043] Synthesis of Hydrophobic Monomers Containing Polyethers

[0044] (1) Dissolve oleic acid in dichloromethane, slowly add thionyl chloride solution dropwise at a molar ratio of 1:1.15, reflux reaction under ice bath conditions for 8 hours, pass the generated tail gas into NaOH solution for processing, and react After cooling, the organic solvent dichloromethane was removed by rotary evaporation with a rotary evaporator, and a light yellow solid was obtained by suction filtration, and vacuum-dried to constant weight to finally obtain the intermediate oleic acid chloride;

[0045](2) The intermediate oleic acid chloride obtained in the first step reaction and allyl polyethylene glycol-1000 (APEG-1000) are reacted at a molar ratio of 1:1.1 to 1.2 to obtain a polyether monomer; first, the APEG -1000 was added to a three-neck round bottom flask, and anhydrous ethanol solution was added to dissolve it. After it was completely dissolved, it was transferred to an ice bath, and a ...

Embodiment 2

[0047] Synthesis of Hydrophobic Monomers Containing Polyethers

[0048] (1) Dissolve erucic acid in dichloromethane, slowly add thionyl chloride solution dropwise at a molar ratio of 1:1.15, reflux reaction for 8 hours under ice-bath conditions, pass the generated tail gas into NaOH solution for processing, and react After cooling, use a rotary evaporator to remove the organic solvent dichloromethane, filter with suction to obtain a light yellow solid, dry it in vacuum to constant weight, and finally obtain the intermediate erucic acid chloride;

[0049] (2) The intermediate erucic acid chloride obtained in the first step reaction and allyl polyethylene glycol-1000 (APEG-1000) are reacted at a molar ratio of 1:1.1 to 1.2 to obtain a polyether monomer; first, the APEG -1000 into a three-neck round bottom flask, add absolute ethanol solution to dissolve, after complete dissolution, transfer to ice bath condition, slowly add the mixed solution of absolute ethanol containing inter...

Embodiment 3

[0051] (1) Add 30g of acrylamide, 4g of acrylic acid, 6g of 2-acrylamido-2-methylpropanesulfonic acid, 2g of N,N-dimethylallyl octadecyl ammonium and 0.5g of polyacrylic acid into a 200ml beaker The ether monomer APOA was made into an aqueous solution with a monomer concentration of 30%, and sodium dodecyl sulfate (SDS) accounting for 1% of the total monomer concentration was added at the same time, and stirred until a clear solution was obtained.

[0052] (2) After the solution is fully mixed, pass nitrogen gas for 30 minutes to remove dissolved oxygen in the water.

[0053] (3) With 2,2-azobisisobutylamidine dihydrochloride (V50) as the initiator, the initiator accounts for 0.2% of the total monomer concentration, and the free radical Aqueous solution polymerization, react for 6 hours to get the required hydrophobic association polymer, finally cut the obtained hydrophobic association polymer into pieces, soak and dry with absolute ethanol, grind into powder, and obtain high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com