Polyhydroxy cage-shaped P-N synergistic flame retardant and synthesis method thereof

A polyhydroxyl cage-like, synergistic flame retardant technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. , The effect of improving mechanical properties and high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

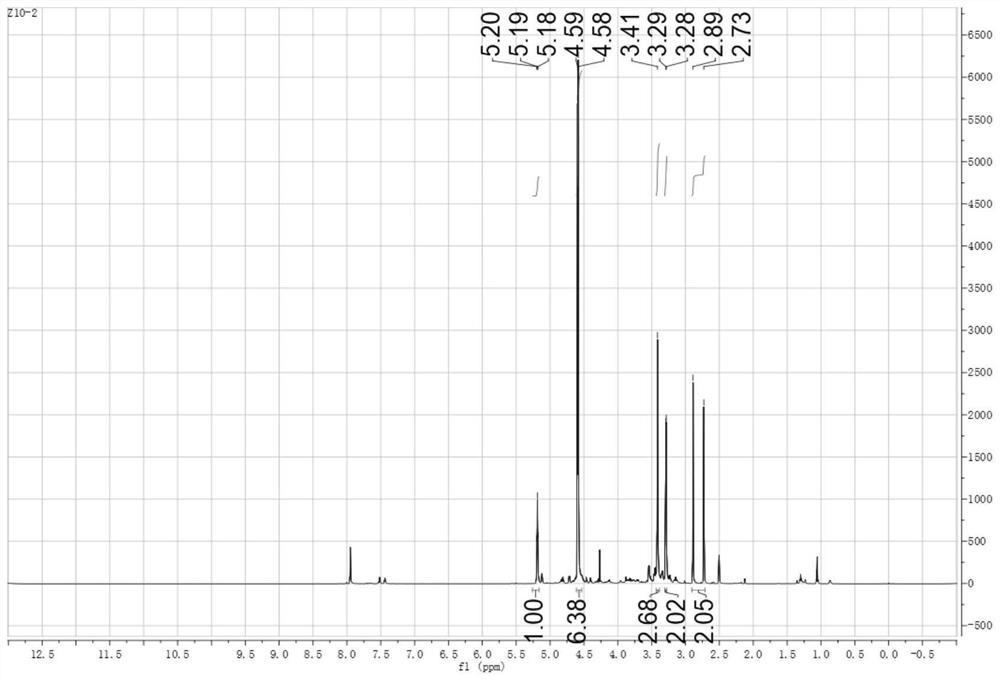

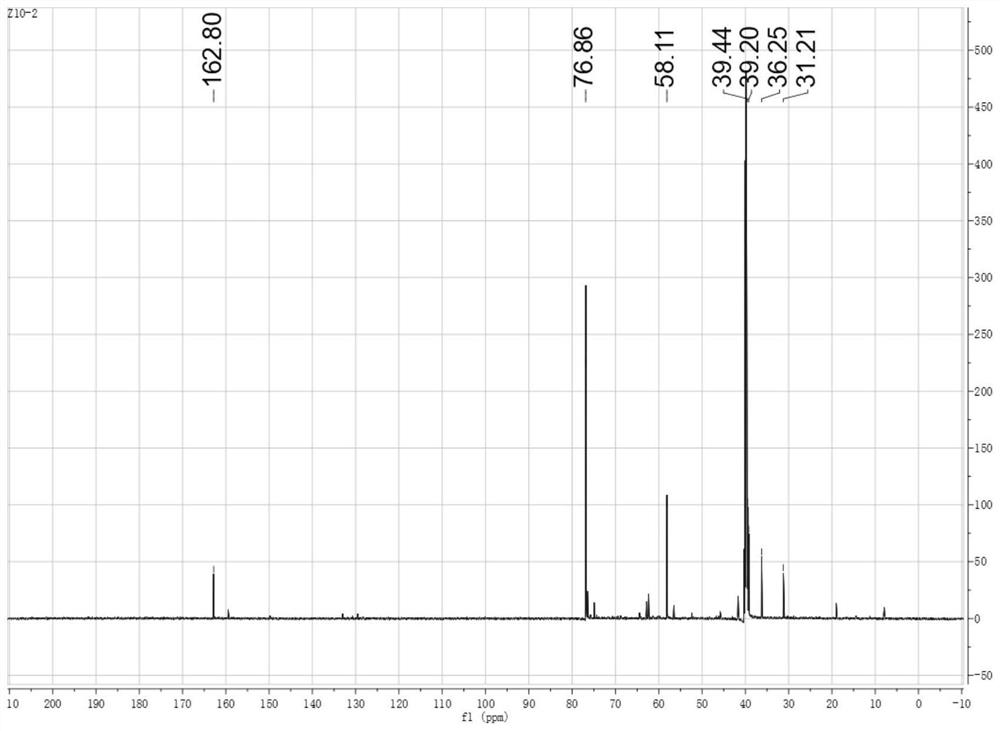

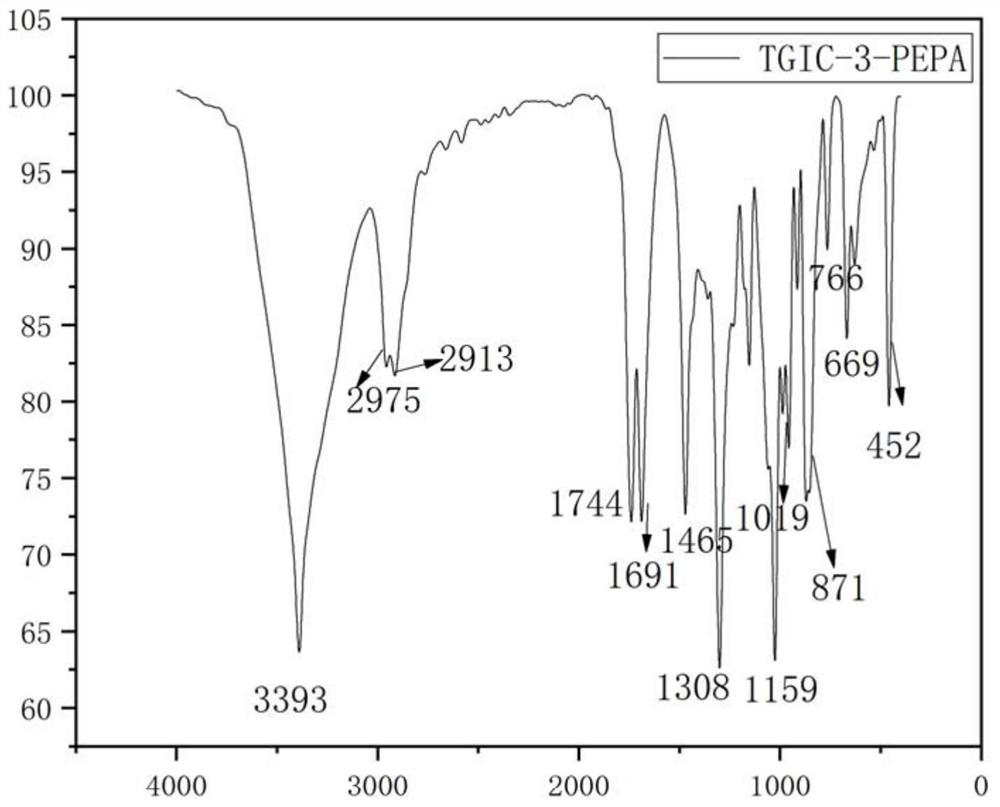

[0031] A kind of synthetic method of polyhydroxyl cage-like P-N synergistic flame retardant, the steps that it comprises are as follows:

[0032] a. Accurately weigh 0.05 mol of TGIC and 0.15 mol of PEPA and dissolve them in 150 mL and 100 mL of N,N-dimethylformamide (DMF), respectively;

[0033] b. After adding the PEPA solution into the reactor, add 0.15g of benzyltriethylammonium chloride;

[0034] c. Adjust the temperature of the oil bath to the condensation reaction temperature of 100°C, and drip the TGIC solution into the reaction kettle, and the dripping time is 20 hours;

[0035] d. Continue to raise the temperature to 100° C., feed nitrogen gas at a rate of 10 mL / min, avoid the influence of moisture in the air on the reaction, and react at a constant temperature for 8 hours.

[0036] e. After the reaction is completed, use a rotary evaporator to spin dry the DMF, extract the reaction product with methanol, and then filter it to leave the part soluble in methanol, and...

Embodiment 2

[0038] A kind of synthetic method of polyhydroxyl cage-like P-N synergistic flame retardant, the steps that it comprises are as follows:

[0039] a. Accurately weigh 0.1mol of TGIC and 0.36mol of PEPA and dissolve them in 300mL and 200mL of DMF respectively;

[0040] B, the PEPA solution is added in the reactor, then add 1g of benzyltriethylammonium chloride;

[0041] c. Adjust the temperature of the oil bath to the condensation reaction temperature of 110°C, and drip the TGIC solution into the reaction kettle with a dripping time of 15 hours;

[0042] d. Continue to raise the temperature to 110° C., feed nitrogen gas at a rate of 15 mL / min, avoid the influence of moisture in the air on the reaction, and react at a constant temperature for 8 hours.

[0043] e. After the reaction is completed, use a rotary evaporator to spin dry the DMF, extract the reaction product with methanol, filter the part soluble in methanol, and spin dry again; use ethanol to extract, take the part so...

Embodiment 3

[0045] A kind of synthetic method of polyhydroxyl cage-like P-N synergistic flame retardant, the steps that it comprises are as follows:

[0046] a. Accurately weigh 0.25mol of TGIC and 1mol of PEPA and dissolve them in 750mL and 500mL of DMF respectively;

[0047] B, the benzyltriethylammonium chloride of 7.4g is added after the PEPA solution is joined in the reactor;

[0048] c. Adjust the temperature of the oil bath to the condensation reaction temperature of 120°C, and drip the TGIC solution into the reaction kettle for 16 hours;

[0049]d. Continue to raise the temperature to 120° C., feed nitrogen gas at a rate of 20 mL / min, avoid the influence of moisture in the air on the reaction, and react at a constant temperature for 11 hours.

[0050] e. After the reaction is completed, use a rotary evaporator to spin dry the DMF, extract the sample with methanol, and then filter with suction to leave the part soluble in methanol, and spin dry again; use ethanol to extract the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com