High-efficiency high-energy-storage sodium niobate-based ceramic material and preparation method thereof

A ceramic material and sodium niobate-based technology, applied in the field of high-efficiency and high-energy-storage sodium niobate-based ceramic materials and their preparation, can solve the problems of low energy storage density, short service life, small discharge current, etc., and achieve high energy storage capacity. The effect of energy density, large output current, and long charge and discharge life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

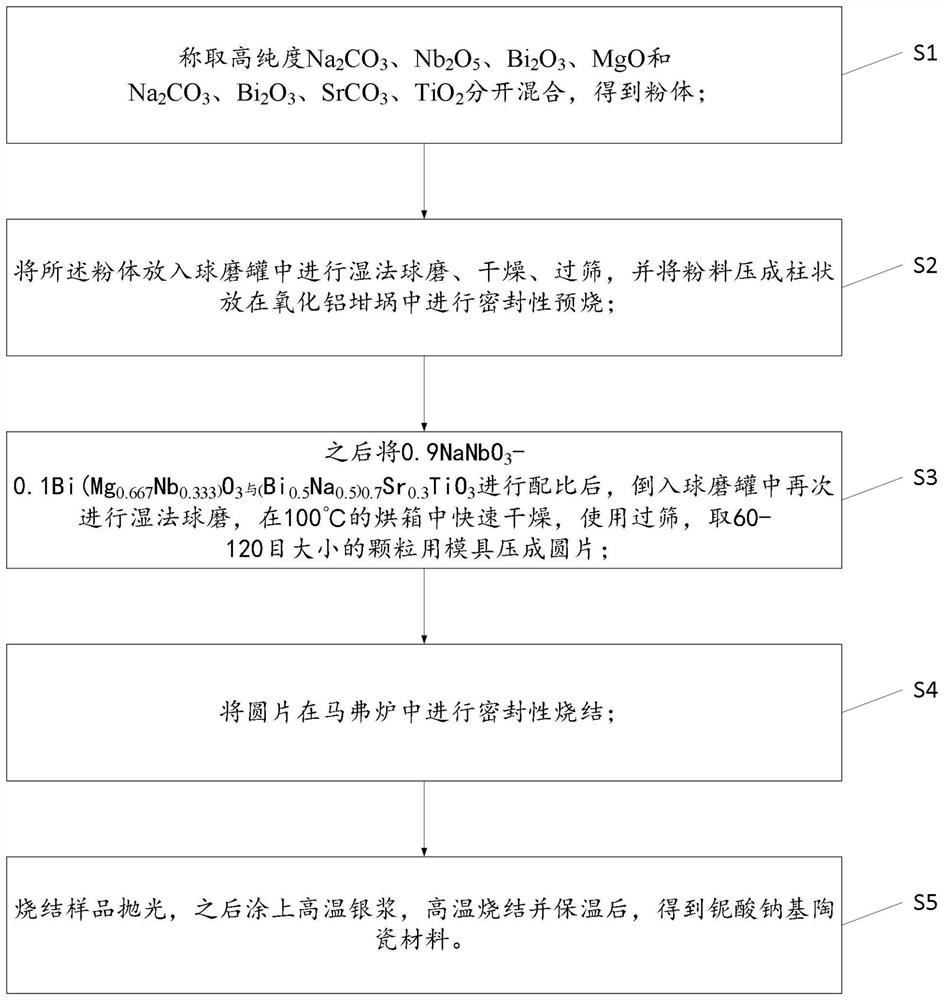

Method used

Image

Examples

Embodiment Construction

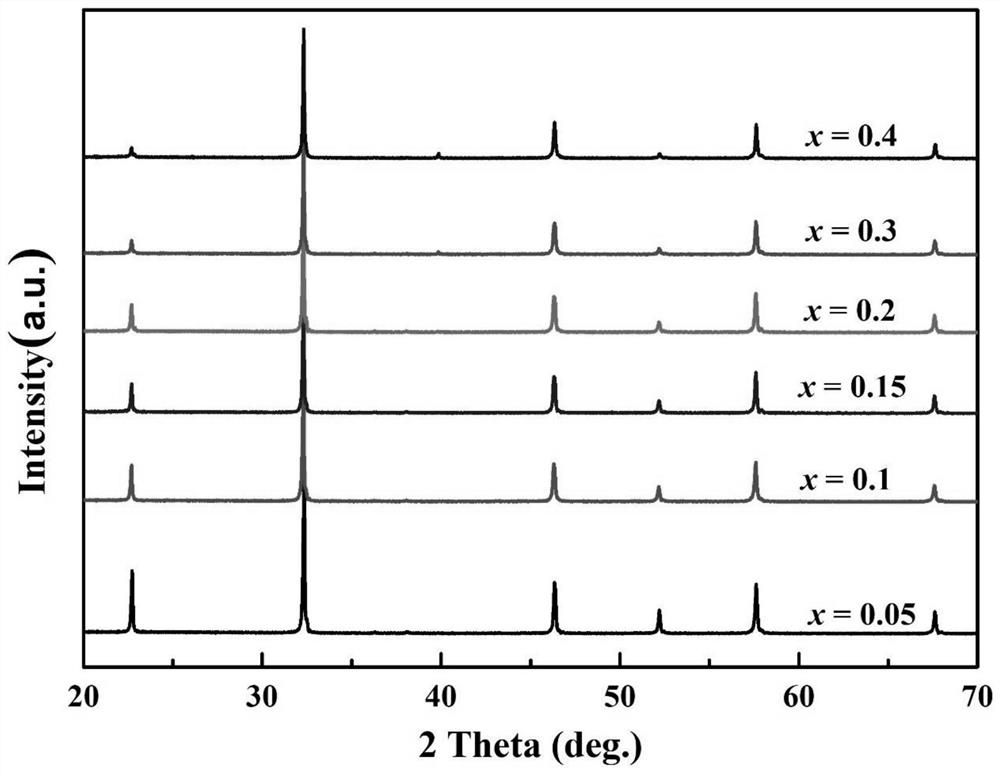

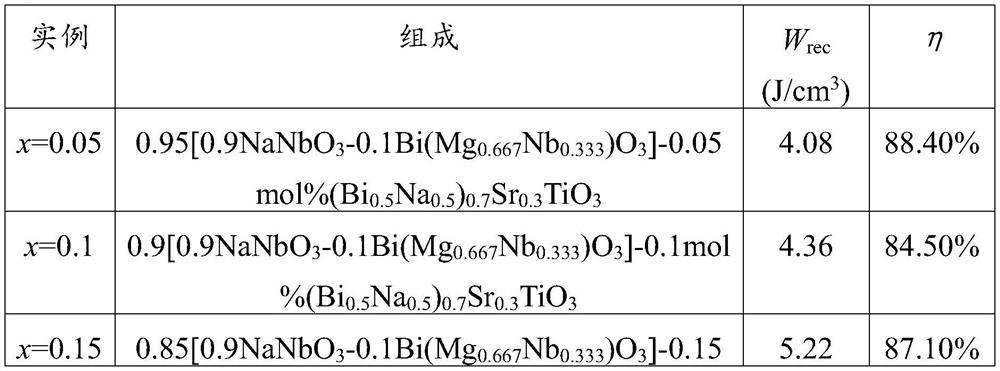

[0026] The present invention introduces (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 with 0.9NaNbO 3 -0.1Bi(Mg 0.667 Nb 0.333 )O 3 A uniform solid solution is formed to increase the maximum polarization strength of the ceramic material, thereby obtaining a dielectric ceramic material with high energy storage density.

[0027] Introduced in the present invention (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 has the following advantages:

[0028] (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 The hybridization of the 6s of Bi and the 2p orbital of O is beneficial to obtain high saturation polarization.

[0029] When introduced (Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 TiO 3 When, [(Bi 0.5 Na 0.5 ) 0.7 Sr 0.3 ] 2+ and Ti 4+ respectively into 0.9NaNbO 3 -0.1Bi(Mg 0.667 Nb 0.333 )O 3 The A-site and B-site of the ceramic further destroy its long-range ferroelectric ordered structure, promote the formation of polar nano-micro-domains, and are beneficial to obtain low remnant polarization.

[0030] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com