Frequency conversion control system of boiler air pre-heater

A frequency conversion control, air preheater technology, applied in the control system, motor control, motor generator control, etc., can solve the problems of air preheater loss of power, reduce the reliability of the air preheater, poor reliability, etc., to improve safety and stability The ability to operate, reduce the risk of boiler shutdown, and ensure the reliable effect of power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

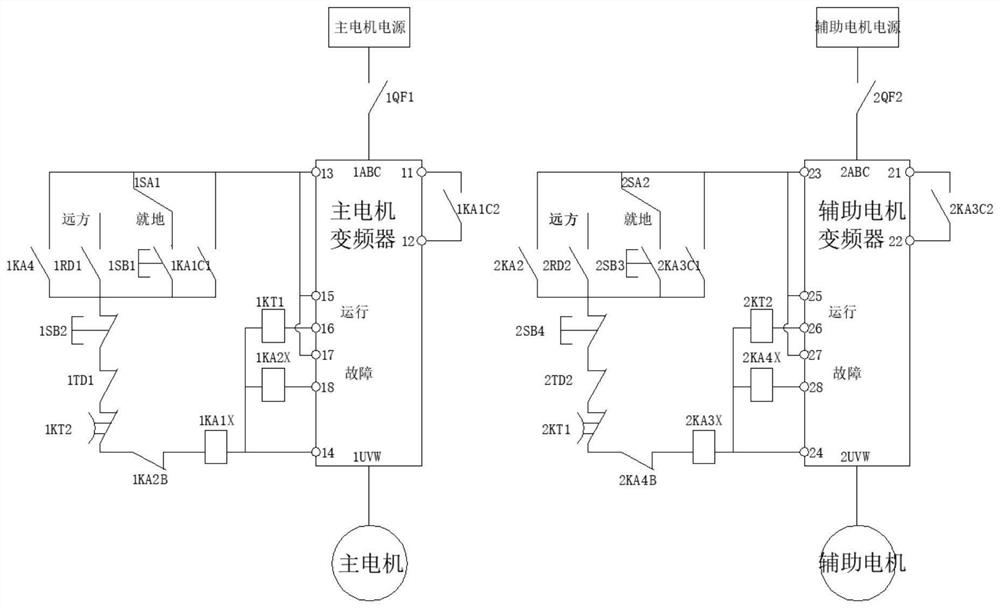

[0049] Main motor starts

[0050] When the frequency converter of the auxiliary motor is in the stopped state and the first remote local transfer switch 1SA1 of the main motor is set at the local position, the first local start button 1SB1 is pressed, or the first remote local transfer switch 1SA1 of the main motor is set at the remote position When the first remote start button 1RD1 is pressed, the first electrified relay coil 1KA1X is energized to act, and the first normally open contact 1KA1C1 of the first electrified relay connected to the No. 13 contact 13 of the main motor inverter is closed to realize the first electrified The live function of the relay coil 1KA1X closes the second normally open contact 1KA1C2 of the first live relay connected to the No. 11 contact 11 of the main motor inverter, and realizes the conduction of the No. 11 contact 11 and No. 12 contact 12 of the main motor inverter. The frequency converter of the main motor starts, and the input terminal 1...

Embodiment 2

[0053] Auxiliary motor start

[0054]When the frequency converter of the main motor is in the stopped state and the second remote local transfer switch 2SA2 of the auxiliary motor is set at the local position, the second local start button 2SB3 is pressed, or the second remote local transfer switch 2SA2 of the auxiliary motor is set at the remote position Press the second remote start button 2RD2, the third electrified relay coil 2KA3X is energized, and the first normally open contact 2KA3C1 of the third electrified relay connected to the auxiliary motor frequency converter No. 23 contact 23 is closed to realize the third electrified relay coil 2KA3X The function of keeping live is to close the second normally open contact 2KA3C2 of the third live relay connected to the 21st contact 21 of the auxiliary motor inverter to realize the conduction of the 21st contact 21 and the 22nd contact 22 of the auxiliary motor inverter, and the auxiliary motor frequency conversion In this pro...

Embodiment 3

[0057] main motor stop

[0058] When the frequency converter of the main motor is in running state, the first remote local transfer switch 1SA1 of the main motor is set at the local position and the first local stop button 1SB2 is pressed, or the first remote local transfer switch 1SA1 of the main motor is set at the remote position Press the first remote stop button 1TD1, at this time the first charged relay coil 1KA1X will be de-energized and return, and the first normally open contact 1KA1C1 of the first charged relay connected to the No. 13 contact point 13 of the main motor inverter will be separated to release the first charged The function of keeping the electrification of the relay coil 1KA1X separates the second normally open contact 1KA1C2 of the first electrified relay connected to the No. 11 contact 11 of the main motor inverter, and releases the conduction between the No. 11 contact 11 and the No. 12 contact 12 of the main motor inverter. The frequency converter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com