Double-runner hydraulic vibration isolation device

A dual-channel, first-channel technology, applied in the direction of shock absorber, shock absorber-spring combination, spring/shock absorber, etc., can solve the problems of poor ride comfort and achieve stable shock absorption and outstanding vibration isolation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

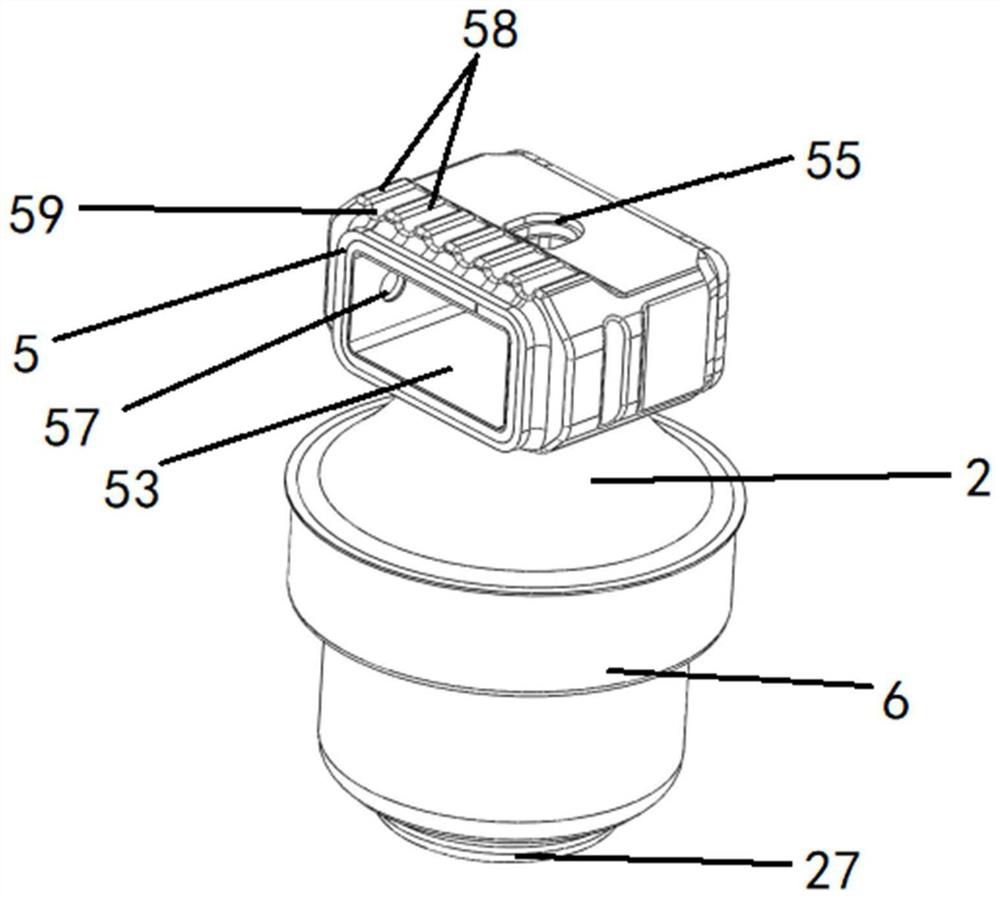

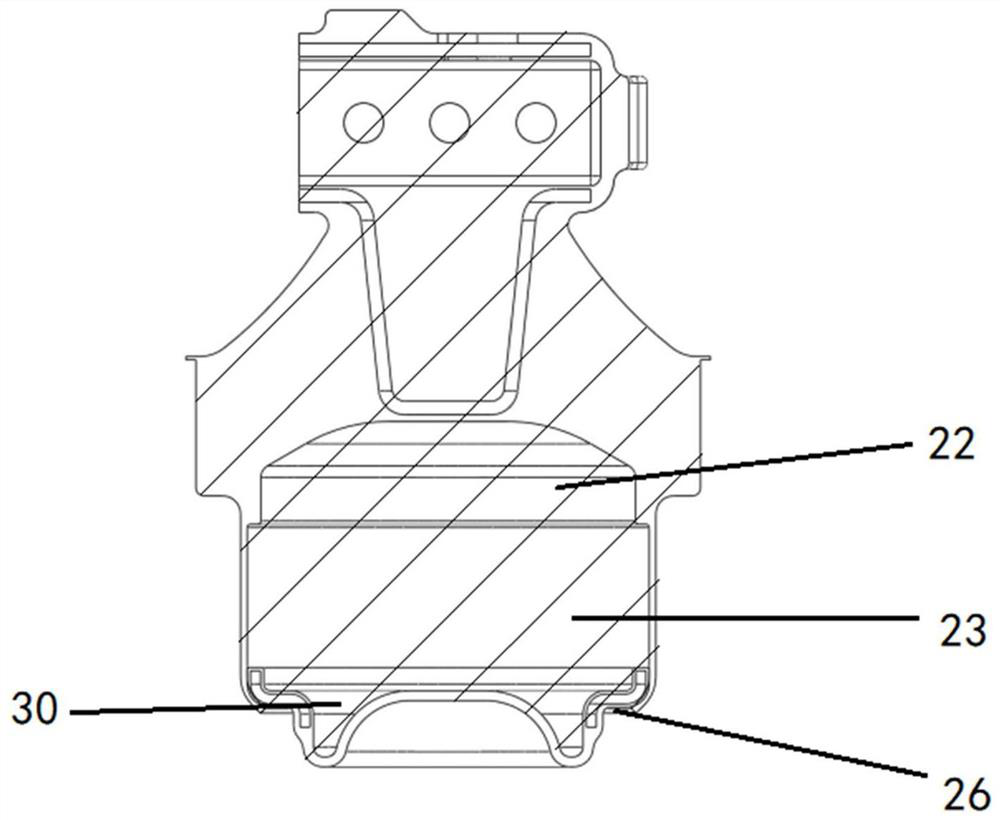

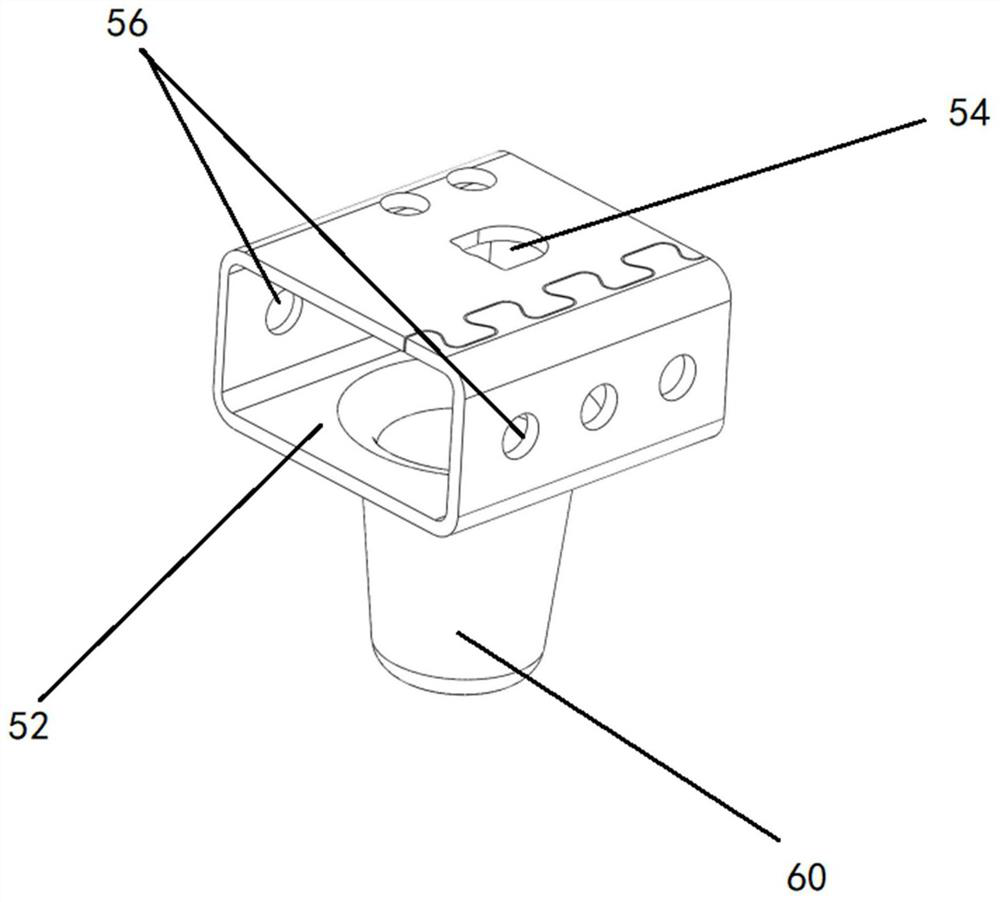

[0042] Such as Figure 1-8As shown, a hydraulic vibration isolation device with double channels 12 includes a valve body 1, and an inner cavity 7 and a flow channel 12 are arranged on the valve body 1. The inner cavity 7 is arranged in the valve body 1, and the flow channel 12 surrounds the valve body. The side of the outer surface of the body 1 is set; the flow channel 12 includes a flow channel inlet 16, a first flow channel outlet 13 and a second flow channel outlet 17, and the flow channel inlet 16 and the second flow channel outlet 17 are arranged on both sides of the flow channel 12 end, the first flow channel outlet 13 is arranged between the flow channel inlet 16 and the second flow channel outlet 17, the first flow channel outlet 13 communicates the flow channel 12 with the inner cavity 7; between the flow channel inlet 16 and the first flow channel outlet 13 It is the first flow channel 14, and the second flow channel 15 is between the first flow channel outlet 13 an...

Embodiment 2

[0059] Such as Figure 11-12 As shown, in this embodiment, a restrictor plate 150 is also provided in the inner cavity, and through holes are distributed on the restrictor plate 150; the decoupling plate covers the upper surface of the restrictor plate 150, and the restrictor plate The horizontal height of 150 is higher than the horizontal height of the outlet of the first flow channel; in this embodiment, the decoupling disc is placed in a position convenient to open through the restrictor plate 150, so that the decoupling disc can be stably opened when the damping fluid moves upward , so as to ensure the shock absorption effect of the present invention, and avoid the decoupling disc from clogging the inner cavity to cause negative pressure in the liquid chamber, thereby causing abnormal cavitation noise, and further improving the riding experience of the vehicle; and the through holes arranged in a distributed manner make The damping fluid is more stable when it passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com