Roof-cutting pressure-relief coal-pillar-free self-roadway-forming mining design and evaluation method

A technology of roof cutting pressure relief and evaluation method, which is applied in mining equipment, ground mining, earthwork drilling and other directions, can solve the problems of frequent safety accidents, time-consuming and labor-intensive, and large amount of roadway excavation, so as to save coal resources and reduce mining costs. The effect of low coal cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

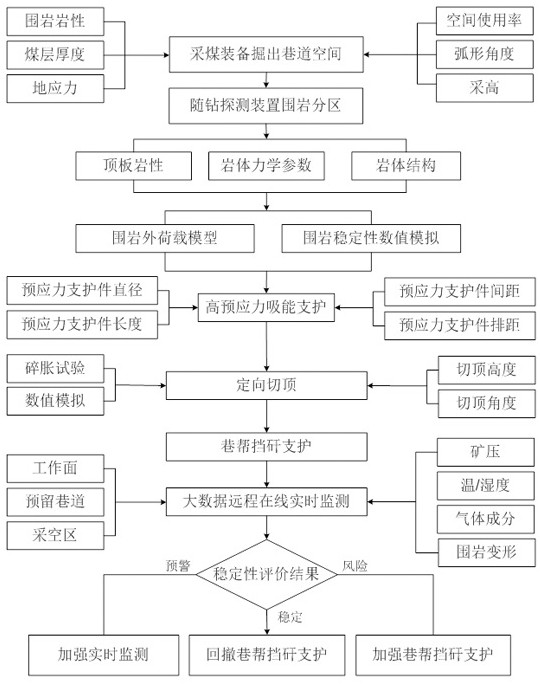

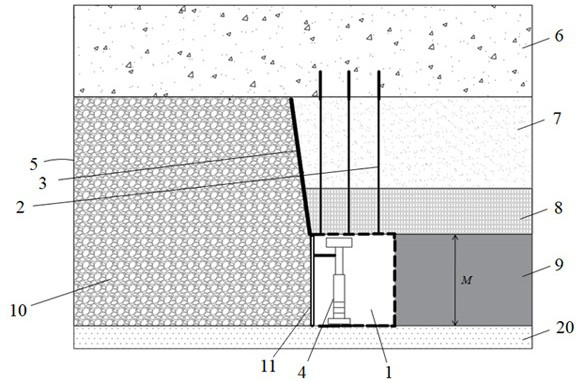

[0019] like Figure 1 to Figure 3 As shown, the mining design and evaluation method of roof cutting and pressure relief without coal pillar self-forming roadway of the present invention includes steps:

[0020] 1) In the process of using coal mining equipment to carry out coal mining operations along the length direction of the working face, excavate the roadway space at the predetermined position of the coal seam 9 at the same time;

[0021] 2) Use the detection-while-drilling device to partition the excavated roadway 1 according to the equivalent rock mass strength, and divide multiple surrounding rock areas;

[0022] 3) Determine the prestressed support parameters and roof cutting parameters of each surrounding rock area according to the results of surrounding rock division, that is, the equivalent rock mass strength of each surrounding rock area;

[0023] 4) According to the determined prestress support parameters, perform high prestress energy-absorbing support on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com