Composite continuous pipe gas production method

A technology for coiled tubing and gas production, applied in drilling pipes, casings, production fluids, etc., can solve problems such as affecting production efficiency, high cost, time-consuming and labor-intensive, etc., to improve production efficiency, prolong life cycle, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This embodiment provides a composite continuous tube gas collection method, including:

[0073] S100, a composite continuous tube having a cross-sectional area adjustable working channel is loaded into a gas receiving well, and the gas passage of the gas well includes the working channel;

[0074] S200, when the liquid height of the gas reaches the preset threshold, the cross-sectional area of the working passage is reduced to improve the flow rate of the inner gas in the well through the gas passage.

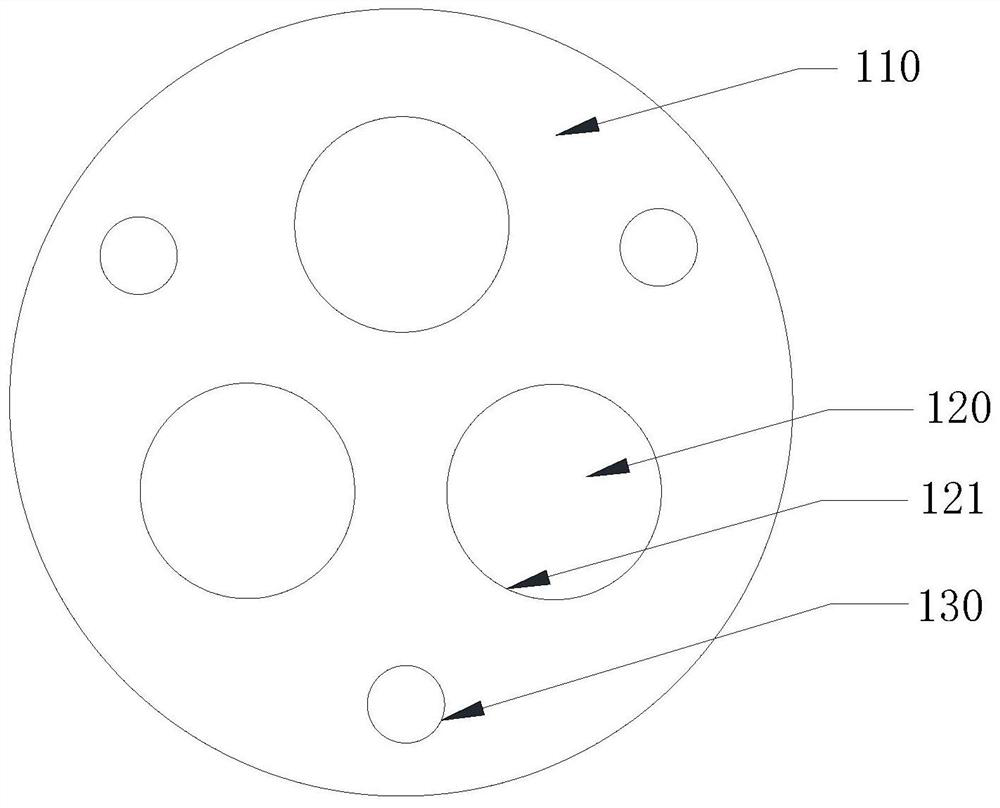

[0075] The working channel consists of three independent channels 120. At the initial stage of the work, the execution unit 500 controls three independent channel 120 simultaneously on, at this time, the gas in the gas is in the maximum gas-free cross-section state.

[0076] When the in-well fluid height reaches the preset threshold, the execution unit 500 controls one of the separate channels 120 to be turned off, at which time the gas well is passed through two separate ...

Embodiment 2

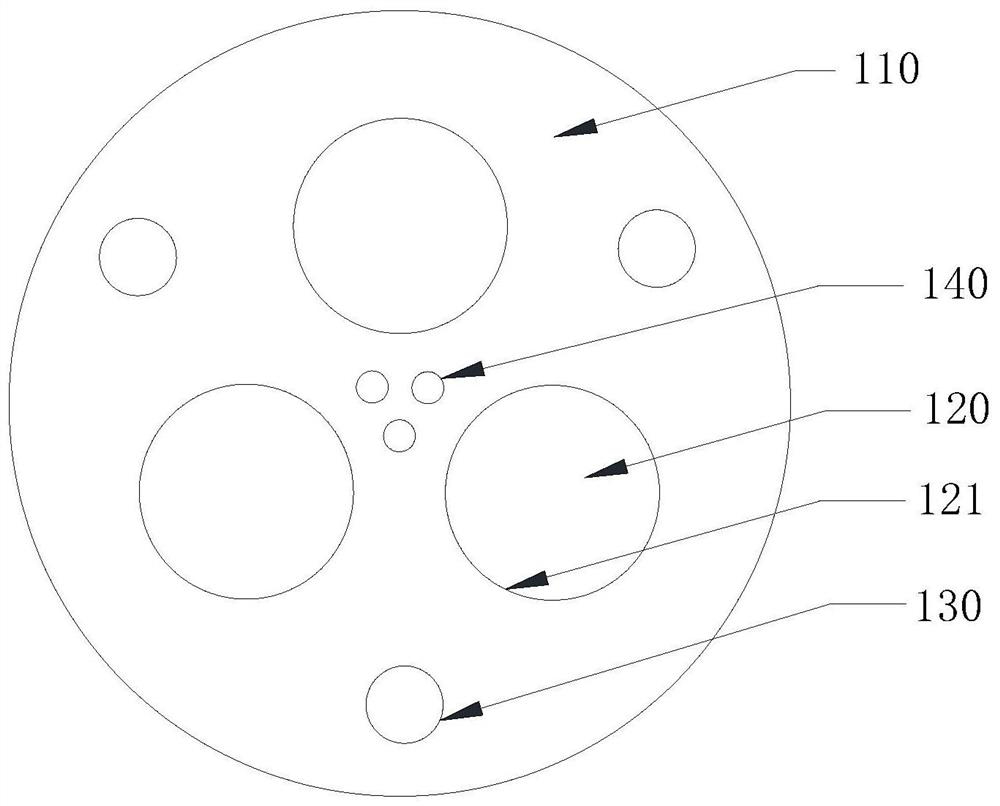

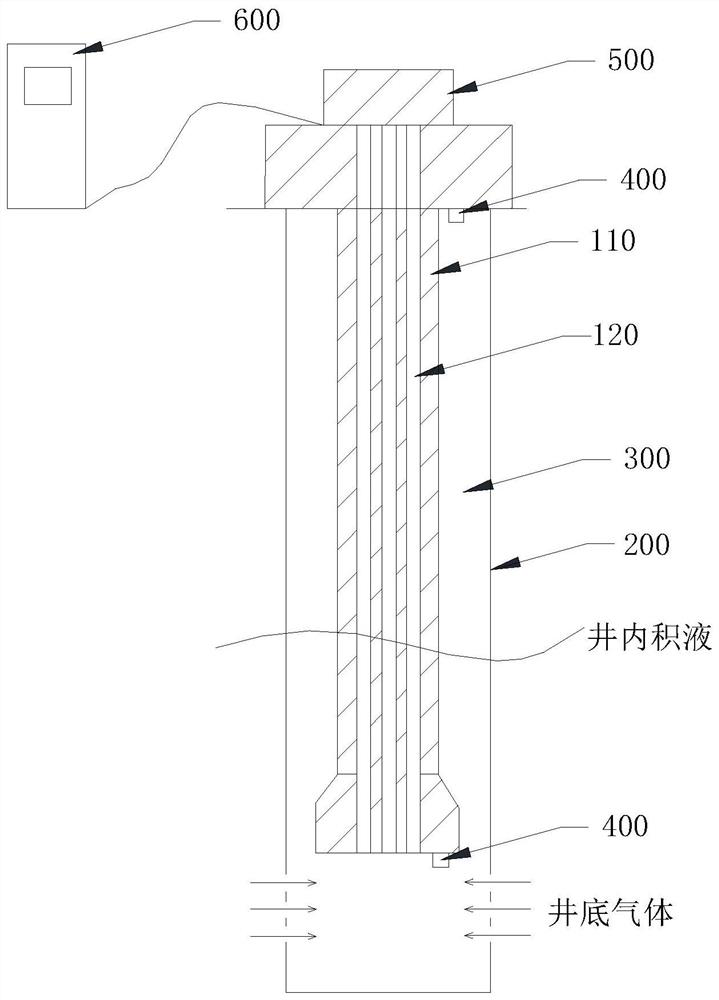

[0080] This embodiment provides a composite continuous pipe gas production method, comprising an adjustable cross-sectional area having a working channel of the tube into a continuous composite gas production well, the working channel 120 comprises three separate channels. Gas production well having within the sleeve 200, the sleeve extends into the composite coiled tubing 200, outer sleeve 200 and the inside of the composite coiled tubing annulus 300 is formed. Gas passage of gas production well comprises three separate annular channels 300 and 120. The environmental gas production well by monitoring the real-time monitoring unit 400.

[0081] In the initial stage of the work, an execution unit 500 controls three separate annular channels 300 and 120 are turned on simultaneously at this time is taken the maximum gas production wells sectional state.

[0082] When the height of the well fluid reaches a predetermined first threshold value, the controller 600 performs the control un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com