Cast-in-place concrete beam slab stair totally-closed formwork reinforcing method

A concrete beam, fully enclosed technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, on-site preparation of building components, etc., can solve the cost of finished product protection and low construction efficiency , poor construction quality and other problems, to achieve the effect of reducing construction efficiency, avoiding unevenness and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

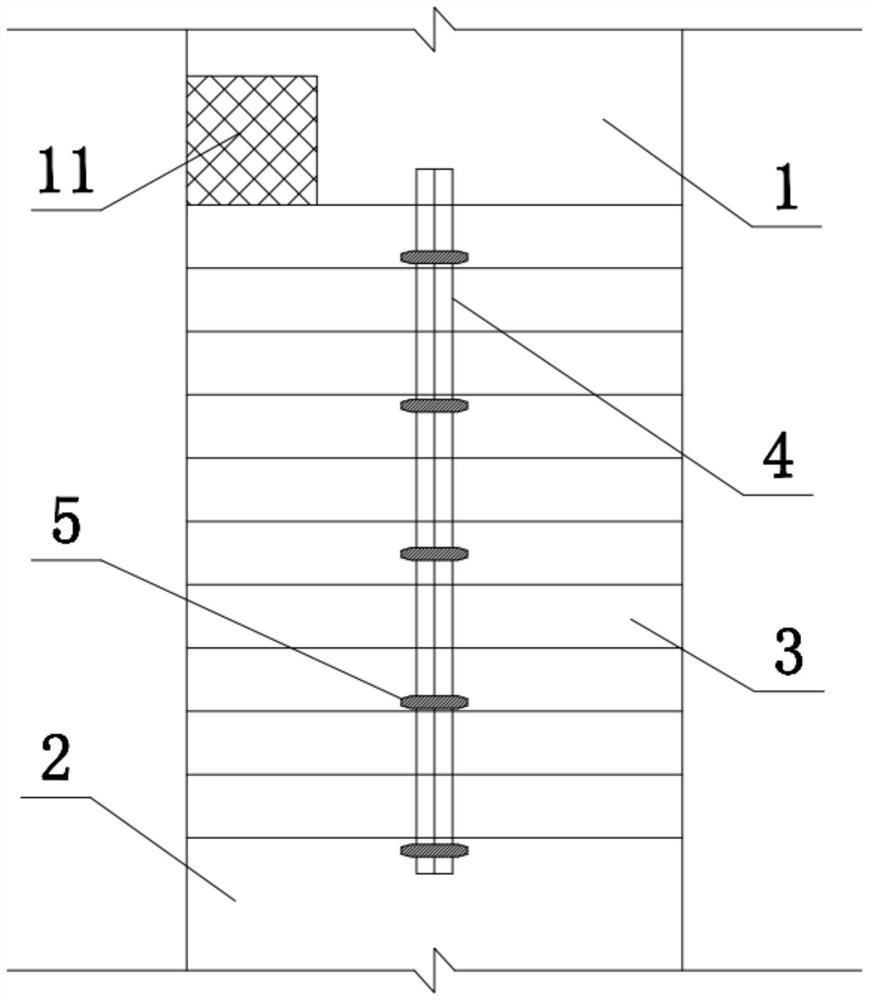

[0042] This embodiment provides a fully enclosed formwork reinforcement method for cast-in-place concrete beam-slab stairs, such as Figure 1-2 , this cast-in-situ concrete beam-slab staircase fully enclosed formwork reinforcement method includes the following steps:

[0043] S1. Erection of stair step formwork 3: The stairwell formwork support system is erected perpendicular to the formwork on the bottom of the steps. The setting of sweeping rods and passages is set up according to the requirements of the formwork construction plan. The horizontal rods of the indoor supporting frame extend to the stairwell and are reliably connected to it , to form a whole, to ensure integrity;

[0044] S2. Installation of the formwork at the bottom of the stair steps: the wood on both sides of the primary and secondary keels is supported by jacking, and the spacing between the square wood of the bottom and secondary keels of the formwork is set;

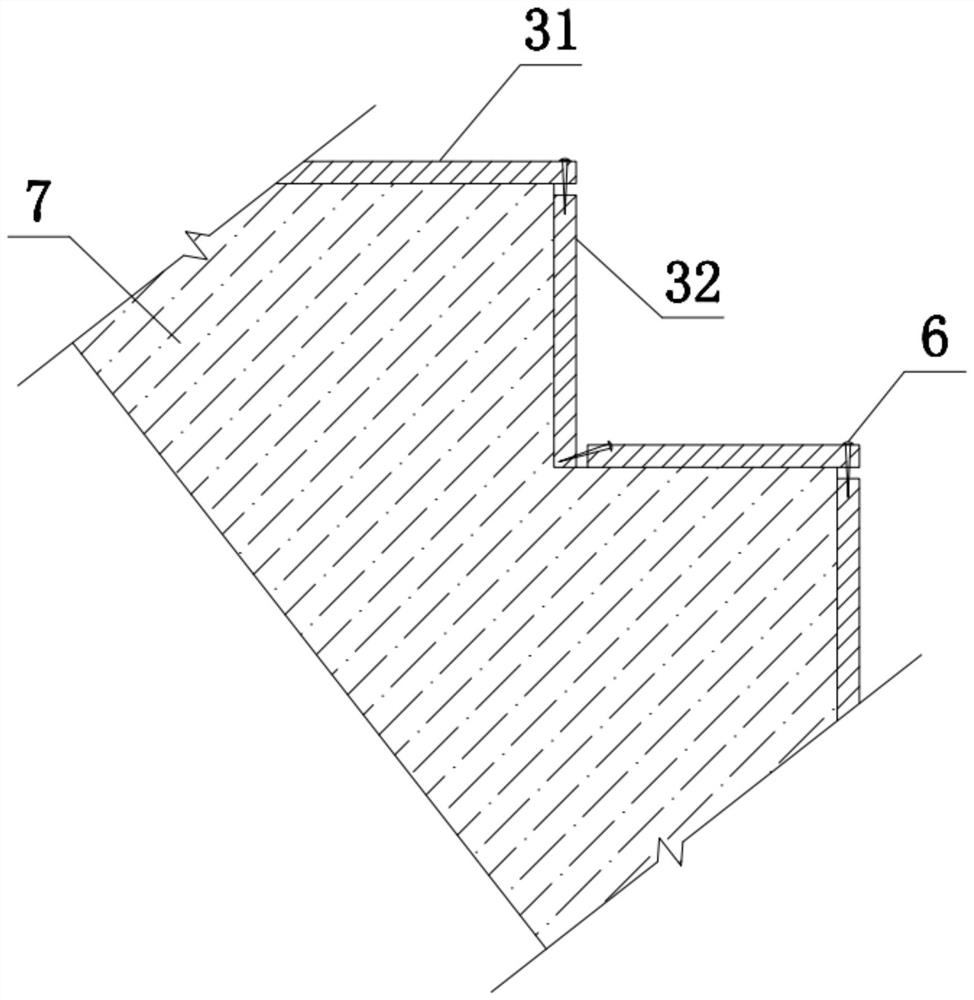

[0045] S3. Binding of steel bars on stair s...

Embodiment 2

[0058] A fully enclosed formwork reinforcement method for cast-in-situ concrete beam-slab stairs includes the following steps:

[0059] S1. Erection of stair step formwork 3: The stairwell formwork support system is erected perpendicular to the formwork on the bottom of the steps. The setting of sweeping rods and passages is set up according to the requirements of the formwork construction plan. The horizontal rods of the indoor supporting frame extend to the stairwell and are reliably connected to it , to form a whole, to ensure integrity;

[0060] S2. Installation of the formwork at the bottom of the stair steps: the wood on both sides of the primary and secondary keels is supported by jacking, and the spacing between the square wood of the bottom and secondary keels of the formwork is set;

[0061] S3. Binding of steel bars on stair steps: The bottom steel bars are bound first, and the upper steel bars are bound when the top surface of the steps and the side formwork 32 are...

Embodiment 3

[0069] A fully enclosed formwork reinforcement method for cast-in-situ concrete beam-slab stairs includes the following steps:

[0070] S1. Erection of stair step formwork 3: The stairwell formwork support system is erected perpendicular to the formwork on the bottom of the steps. The setting of sweeping rods and passages is set up according to the requirements of the formwork construction plan. The horizontal rods of the indoor supporting frame extend to the stairwell and are reliably connected to it , to form a whole, to ensure integrity;

[0071] S2. Installation of the formwork at the bottom of the stair steps: the wood on both sides of the primary and secondary keels is supported by jacking, and the spacing between the square wood of the bottom and secondary keels of the formwork is set;

[0072] S3. Binding of steel bars on stair steps: The bottom steel bars are bound first, and the upper steel bars are bound when the top surface of the steps and the side formwork 32 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com