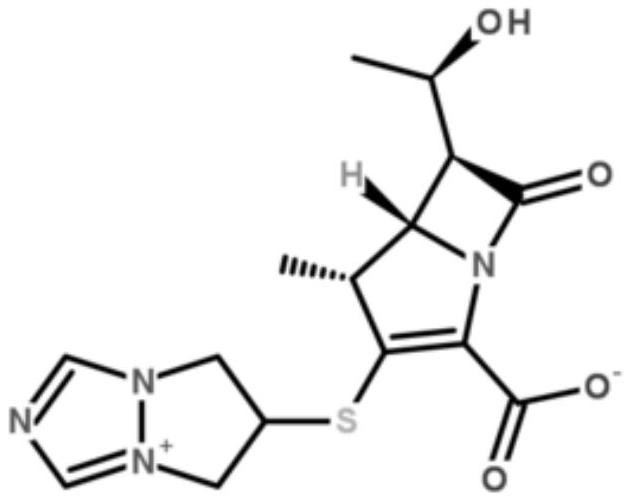

Crystallization method of biapenem

A crystallization technology of biapenem, which is applied in the field of crystallization of biapenem, can solve the problems of large amount of acetone, long crystallization time, low dissolved concentration, etc., and achieve improved yield, good color grade, and reduced material loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 10 g of crude biapenem (purity 98.2%) to 100 ml of water, heat up to 40-50° C. in 10-15 minutes, stir and dissolve until clear and translucent. Add 1.5g of activated carbon and stir for 10 minutes to decolorize, then filter with a 0.45 micron filter membrane to obtain the filtrate; cool down to 10-20°C within 5 minutes to precipitate biapenem crystals, then add 300ml of acetone for further dissolution After crystallization for 2 hours, 9.30 g of biapenem was obtained, with a yield of 93.0%, a purity of 99.4%, and a color grade of 1#.

[0030] Compared with Comparative Example 1, the yield increased by 11%, the purity increased by 0.5%, and the color level decreased from 2# to 1#.

Embodiment 2

[0032] Add 9 g of crude biapenem (purity: 98.2%) into 100 ml of water, heat up to 40-50°C in 10-15 minutes, stir, dissolve and become transparent. Add 1.2g of activated carbon and stir for 10 minutes to decolorize, then filter with a 0.45 micron filter membrane to obtain the filtrate; cool down to 10-20°C within 5 minutes to precipitate biapenem crystals, then add 300ml of acetone for further dissolution Crystallized to obtain 8.01 g of biapenem, with a yield of 89.0%, a purity of 99.5%, and a color grade of 1#. Compared with Comparative Example 1, the yield increased by 9%, the purity increased by 0.8%, and the color level decreased by 1#.

Embodiment 3

[0034] Add 11g of crude biapenem (purity: 98.2%) to 110ml of water, heat up to 40-50°C in 10-15 minutes, stir, dissolve and become transparent. Add 1.5g of activated carbon for decolorization for 10 minutes, then filter with a 0.45 micron filter membrane to obtain the filtrate; rapidly cool down to 10-20°C within 5 minutes to precipitate biapenem crystals, then add 300ml of acetone for further dissolution Crystallized to obtain 10.1 g of biapenem with a yield of 91.9%, a purity of 99.3%, and a color grade of 1#. Compared with Comparative Example 1, the yield increased by 11.9%, the purity increased by 0.6%, and the color level decreased by 1#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com