Lining paper stripping and slitting equipment

A technology of lining paper and lining paper, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of inability to meet demand, slitting and winding, etc., and achieves good winding effect and high degree of automation. , The effect of high surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

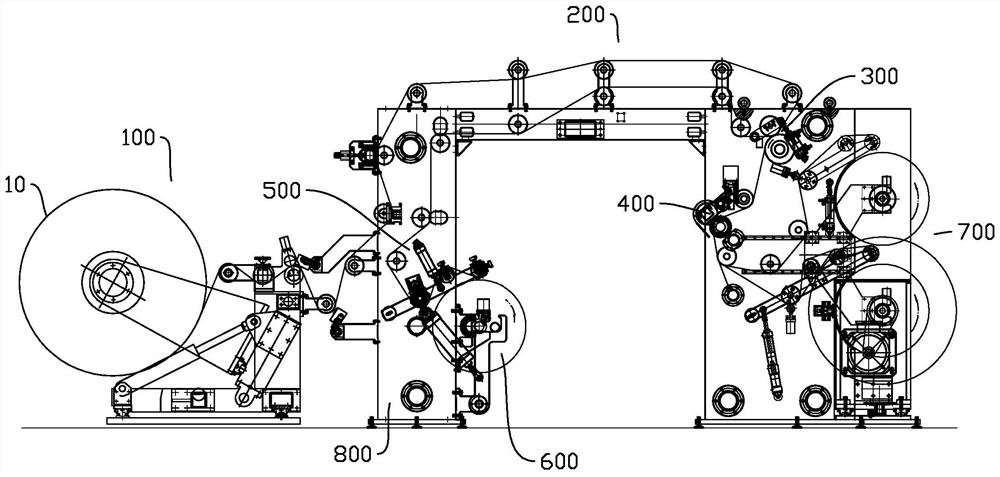

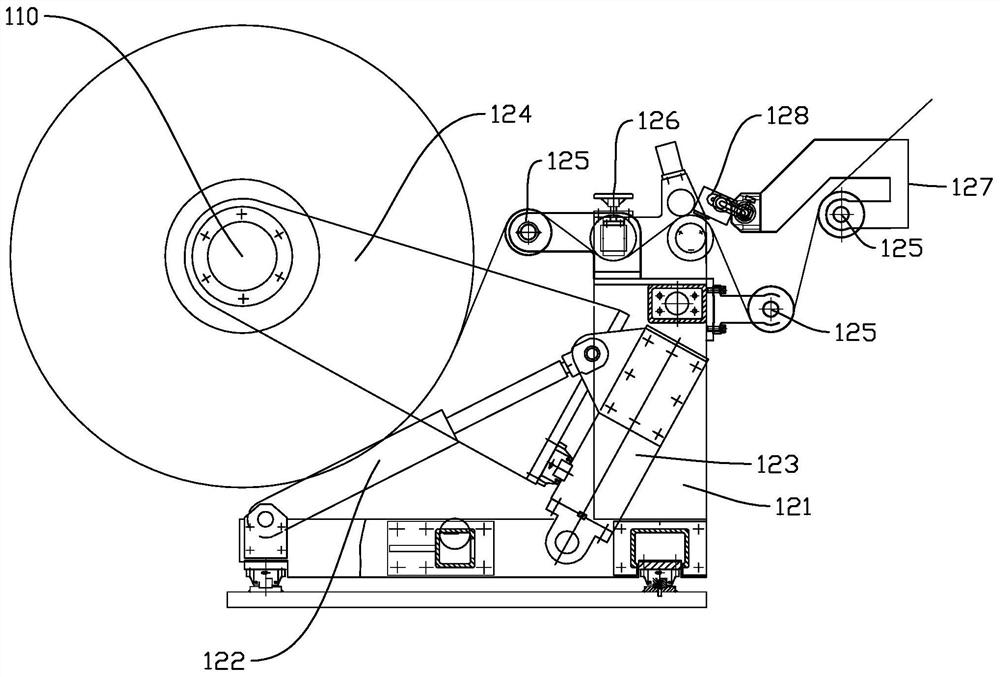

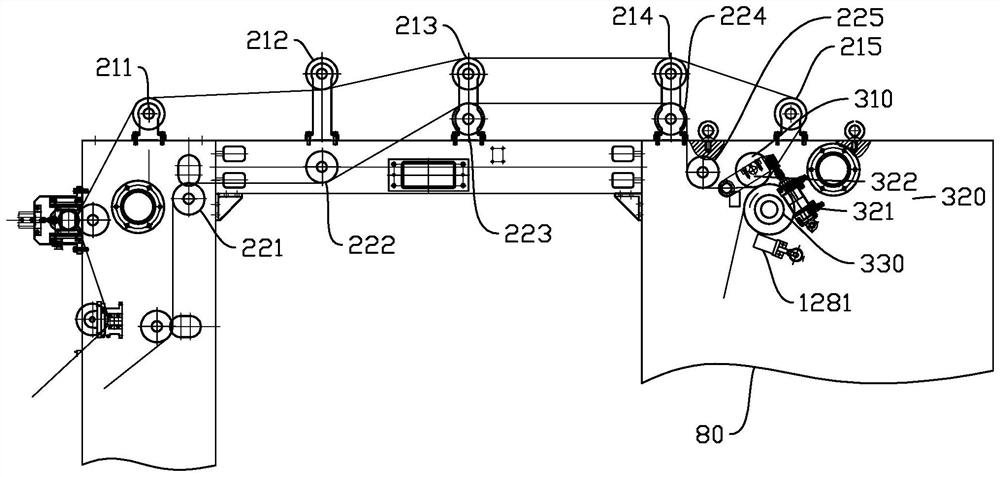

[0026] Such as figure 1 As shown, the liner paper peeling and cutting equipment mainly includes a liner paper unwinding mechanism 100, an intermediate traction mechanism 200, a peeling mechanism 300, a slitting mechanism 400, a peeling film traction mechanism 500, a peeling film winding mechanism 600, a liner paper The winding mechanism 700 and the frame 800, the frame 800 has a gantry structure as a whole, that is, it is composed of two vertical plates and a beam. 1. The peeling film rewinding mechanism 600 is located at the left vertical plate position in the frame, the middle traction mechanism 200 is located at the beam position in the frame, and the peeling mechanism 300, the cutting mechanism 400 and the backing paper rewinding mechanism 700 are located at the machine frame. The right side of the stand in the rack, thereby performing the unwinding, pulling, and peeling processes in sequence. After peeling, it enters the peeling film traction mechanism 500, the peeling fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com