Surface polishing device capable of fixing tubular hardware material

A hardware and tubular technology, which is applied in the field of surface grinding devices, can solve the problems that the grinding thickness cannot be adjusted according to different needs, and the tubular materials cannot be fixed, so as to reduce labor intensity and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

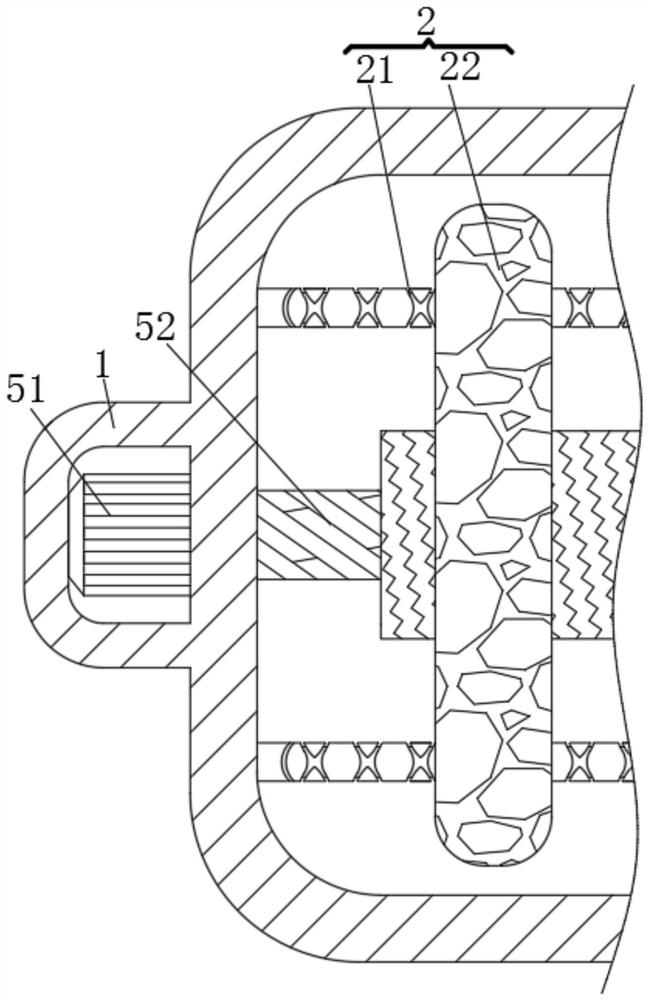

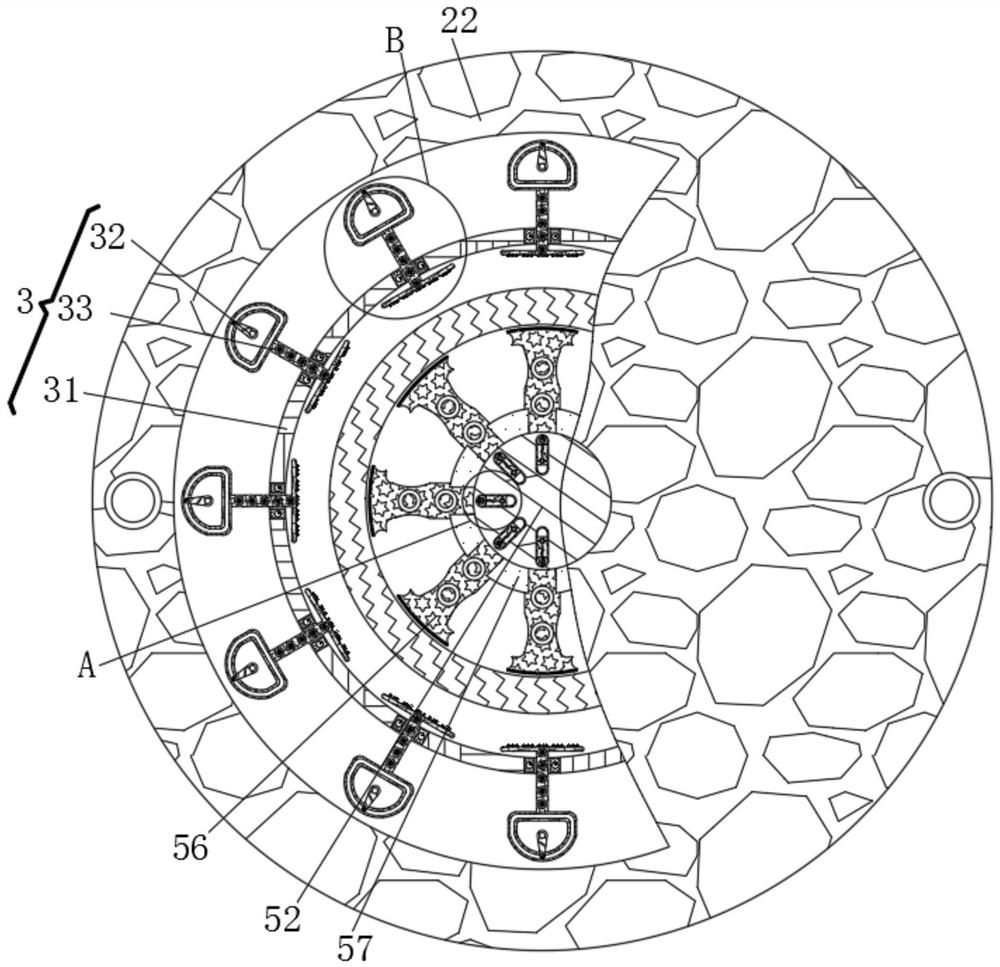

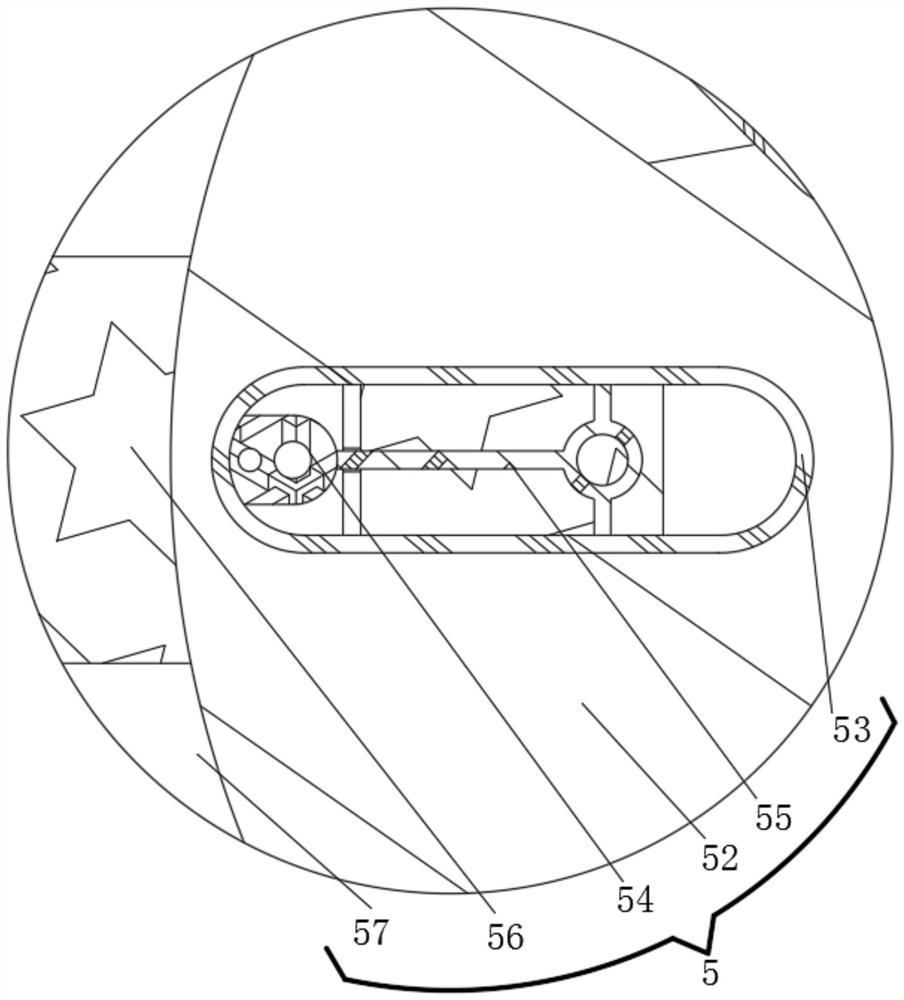

[0032] see figure 1 , 2 , 4. A surface grinding device capable of fixing tubular hardware materials, comprising a casing 1, the interior of the casing 1 is movably connected with a fixing mechanism 5 with a rotating function, and the fixing mechanism 5 includes a motor 51, a rotating shaft 52, a connecting shell 53, and a cylinder 54 , connecting rod 55, ejector rod 56, disc 57, the inside of the housing 1 is fixedly connected with a motor 51, the outside of the motor 51 is fixedly connected with a rotating shaft 52, the inside of the rotating shaft 52 is fixedly connected with a connecting shell 53, and the inside of the connecting shell 53 is fixed Connected with a cylinder 54, the outside of the cylinder 54 is slidably connected with a connecting rod 55, the outside of the rotating shaft 52 is slidably connected with a push rod 56, and the outside of the rotating shaft 52 is fixedly connected with a disc 57, the surface of the disc 57 is provided with a groove, and the push...

Embodiment 2

[0034] see Figure 1-5 , a surface grinding device capable of fixing tubular hardware materials, comprising a casing 1, the inside of the casing 1 is rotatably connected with a moving mechanism 2, the moving mechanism 2 includes a screw 21 and a moving shell 22, and the inside of the casing 1 is rotatably connected with a screw 21 , the outside of the screw rod 21 is slidingly connected with a moving shell 22, the surface of the moving shell 22 is provided with a circular hole, the inner side of the circular hole is provided with a sliding piece, the surface of the screw rod 21 is provided with a ring groove, and the sliding piece is slidably connected to the ring groove. Inside, the inside of the moving mechanism 2 is movably connected with a pushing mechanism 3 with a grinding function. The pushing mechanism 3 includes a baffle 31, a rotating rod 32, and a push rod 33. The inside of the moving shell 22 is fixedly connected with a baffle 31. There is a rotating rod 32 fixedly...

Embodiment 3

[0037] see Figure 1-5 , a surface grinding device capable of fixing tubular hardware materials, comprising a casing 1, the inside of the casing 1 is rotatably connected with a moving mechanism 2, the moving mechanism 2 includes a screw 21 and a moving shell 22, and the inside of the casing 1 is rotatably connected with a screw 21 , the outside of the screw rod 21 is slidingly connected with a moving shell 22, the surface of the moving shell 22 is provided with a circular hole, the inner side of the circular hole is provided with a sliding piece, the surface of the screw rod 21 is provided with a ring groove, and the sliding piece is slidably connected to the ring groove. inside.

[0038] The inside of the moving mechanism 2 is movably connected with a pushing mechanism 3 with a grinding function. The pushing mechanism 3 includes a baffle 31, a rotating rod 32, and a push rod 33. The inside of the moving shell 22 is fixedly connected with a baffle 31, and the inside of the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com