Ultrahigh-speed movable column type gantry machining center

A processing center, ultra-high-speed technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of the movement accuracy of the column to be improved, so as to improve the service life, improve the stability and reduce the thermal wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

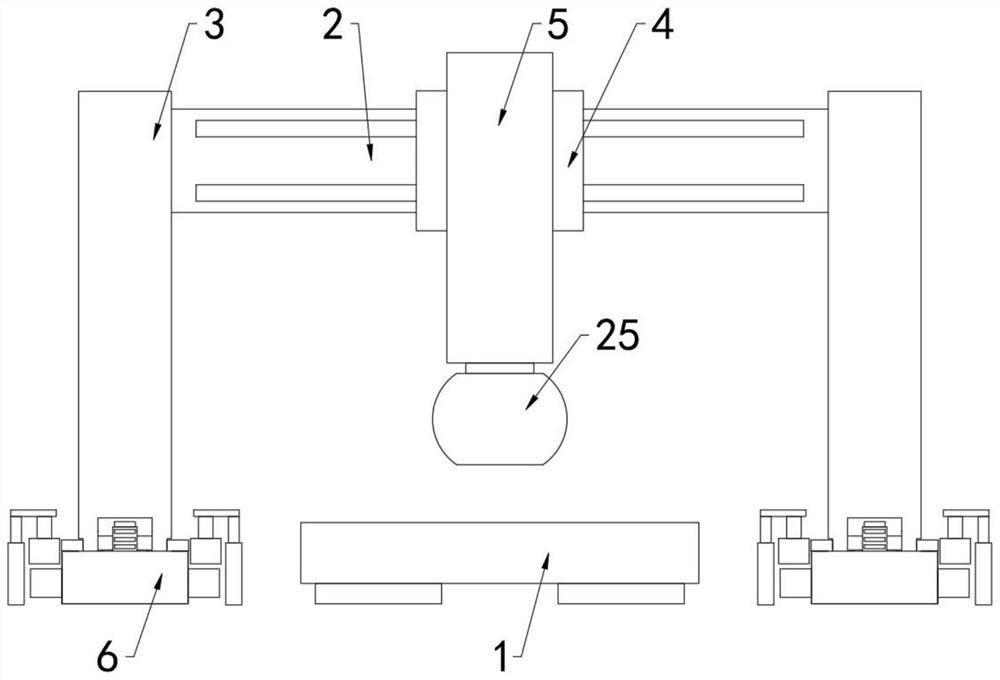

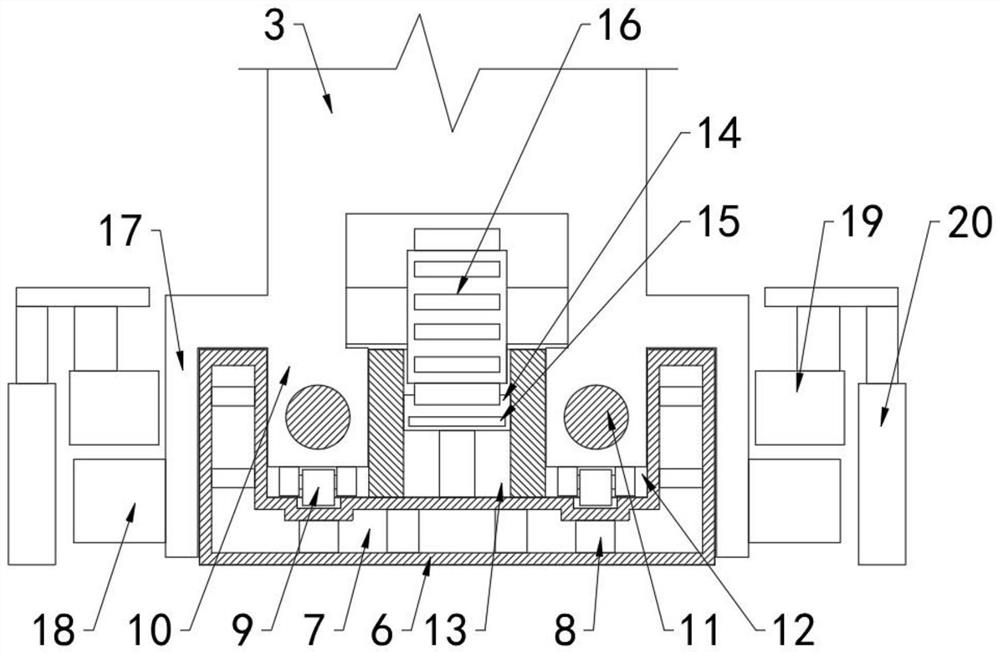

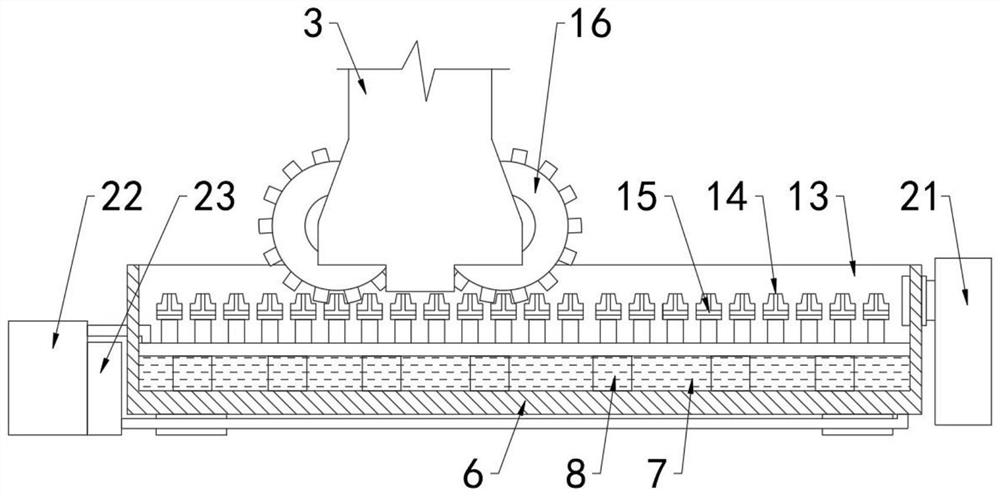

[0030] refer to Figure 1-4 , an ultra-high-speed moving column type gantry machining center, including a workbench 1, a beam 2 arranged above the workbench 1, a ram 4 arranged on the beam 2, a ram 5 installed on the ram 4 and a The processing cutter die 25 at the bottom of the spool 5 also includes:

[0031] Fixed seat 6, fixed seat 6 is symmetrically provided with two groups, and fixed seat 6 top is symmetrically provided with two moving grooves 12, and between two moving grooves 12 is supporting groove 13, is linear equidistant in supporting groove 13 and is provided with multiple a positioning tooth 14, the inside of the fixed seat 6 is provided with a water-cooling cavity 7, and circulating water is provided in the water-cooling cavity 7;

[0032] Column 3, two groups of columns 3 are symmetrically arranged, and the tops of the two groups of columns 3 are installed with the two ends of the beam 2, the bottom ends of the two groups of columns 3 are respectively limited in...

Embodiment 2

[0036] refer to Figure 1-4 , an ultra-high-speed moving column type gantry machining center, including a workbench 1, a beam 2 arranged above the workbench 1, a ram 4 arranged on the beam 2, a ram 5 installed on the ram 4 and a The processing die 25 at the bottom of the sliding column 5 also includes: a fixed seat 6, which is symmetrically provided with two groups, and the top of the fixed seat 6 is symmetrically provided with two moving grooves 12, and between the two moving grooves 12 is a supporting groove 13. A plurality of positioning teeth 14 are provided in a linear equidistant manner in the support groove 13, and a water cooling chamber 7 is provided inside the fixed seat 6, and circulating water is provided in the water cooling chamber 7; the columns 3 and 3 are symmetrically arranged in two groups, and The tops of the two sets of columns 3 are installed on both ends of the crossbeam 2, the bottom ends of the two sets of columns 3 are respectively limited in the two ...

Embodiment 3

[0041] refer to Figure 1-4 , an ultra-high-speed moving column type gantry machining center, including a workbench 1, a beam 2 arranged above the workbench 1, a ram 4 arranged on the beam 2, a ram 5 installed on the ram 4 and a The processing die 25 at the bottom of the sliding column 5 also includes: a fixed seat 6, which is symmetrically provided with two groups, and the top of the fixed seat 6 is symmetrically provided with two moving grooves 12, and between the two moving grooves 12 is a supporting groove 13. A plurality of positioning teeth 14 are provided in a linear equidistant manner in the support groove 13, and a water cooling chamber 7 is provided inside the fixed seat 6, and circulating water is provided in the water cooling chamber 7; the column 3 and the column 3 are symmetrically arranged in two groups, and The tops of the two sets of columns 3 are installed on the two ends of the crossbeam 2, the bottom ends of the two sets of columns 3 are respectively limite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com