Zero emission device and method for VOCs desorption condensation treatment tail gas

A zero-emission, adsorption device technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., to achieve the effects of providing condensation efficiency, increasing return air temperature, and reducing terminal treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: The adsorption device is a single adsorbent adsorption box.

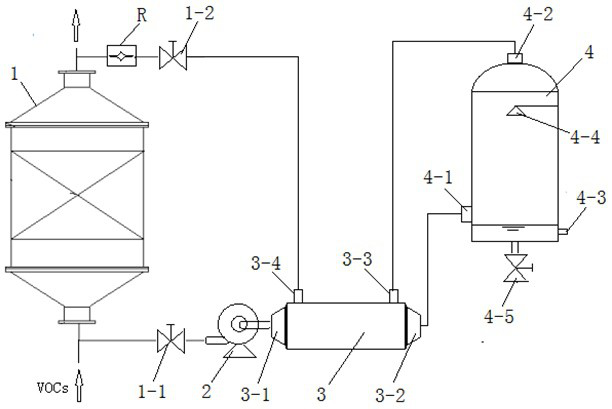

[0050] At present, a single adsorption box is generally used to adsorb VOCs+end treatment. In order to meet the requirements of advanced treatment, this embodiment optimizes a zero-emission device for VOCs desorption and condensation treatment of tail gas, such as figure 1 shown.

[0051] figure 1 Among them, a zero-emission device for VOCs desorption and condensation treatment of tail gas, which is used for the terminal treatment of a single adsorption box. The single adsorption box is a device for absorbing and concentrating VOCs. It has an inlet port for VOCs and an outlet port for VOCs; the air inlet valve 1 The inlet port of -1 is connected with the inlet port of adsorption box 1, which is also the inlet port of VOCs; the inlet port of return air valve 1-2 is connected with the outlet port of adsorption box 1 through heater R, the The connection is also the outlet port of VOCs;

[0052] ...

Embodiment 2

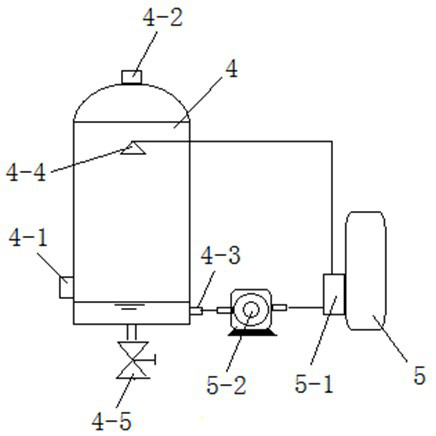

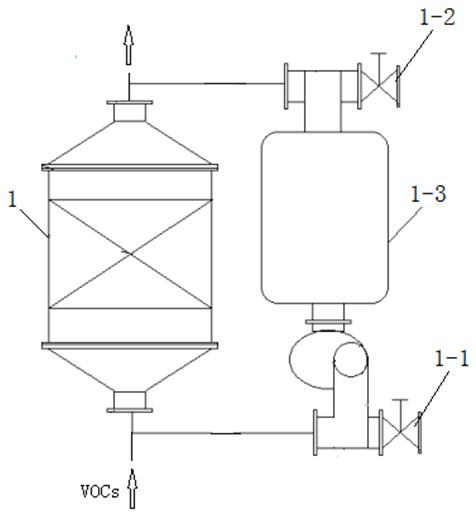

[0088] Example 2: The self-concentrating adsorption box has the advantages of desorption and re-concentration, and the air volume of the terminal treatment is small and the concentration is high. This embodiment is a zero-emission device for VOCs desorption and condensation treatment tail gas preferred for the self-concentrating adsorption box, such as image 3 shown.

[0089] A zero-emission device for VOCs desorption and condensation treatment tail gas, which is used for the terminal treatment of the self-concentration adsorption box. The self-concentration adsorption box includes: a single adsorption box and self-concentration devices 1-3, the structure of the single adsorption box and The single adsorption box of embodiment 1 has the same structure; the air inlet end of the air inlet valve 1-1 of the self-concentrating device 1-3 and the air inlet valve 1-1 of the single adsorption box is communicated with the air outlet end of the air return valve 1-2;

[0090] The self-c...

Embodiment 3

[0101] Embodiment 3: This embodiment is a structural type of the end differential heat exchanger 3 applied in the present invention. The end differential heat exchanger 3 includes: a shell, a hot air inlet 3-1, and a hot air outlet 3-2 , cold air inlet 3-3, cold air outlet 3-4, return air coil 3-5; the housing is rectangular or cylindrical; inside the housing is a hot air chamber, and inside the return air coil 3-5 is Cold air passage; the inlet of the return air coil 3-5 is the cold air inlet 3-3, the outlet of the return air coil 3-5 is the cold air outlet 3-4, and the cold air inlet 3-3 and the cold air outlet 3-4 are connected to the housing On the side wall; the hot air inlet 3-1 and the hot air outlet 3-2 are connected to the two ends of the housing.

[0102] The return air coil 3-5 is a metal coil; the cold air inlet 3-3 and the cold air outlet 3-4 are wire pipes, or quick-connect pipes, and the wire pipes or quick-connect pipes are connected to the return air coil; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com