Device for reducing mechanical loads under and in a functional component such as a PTC element

A technology of positive temperature coefficient and functional components, applied in the direction of resistors with positive temperature coefficient, resistors with negative temperature coefficient, electrical components, etc., can solve the problems of unfavorable heat export, reduce stress level and improve contact Effect of pressure distribution, mechanical stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

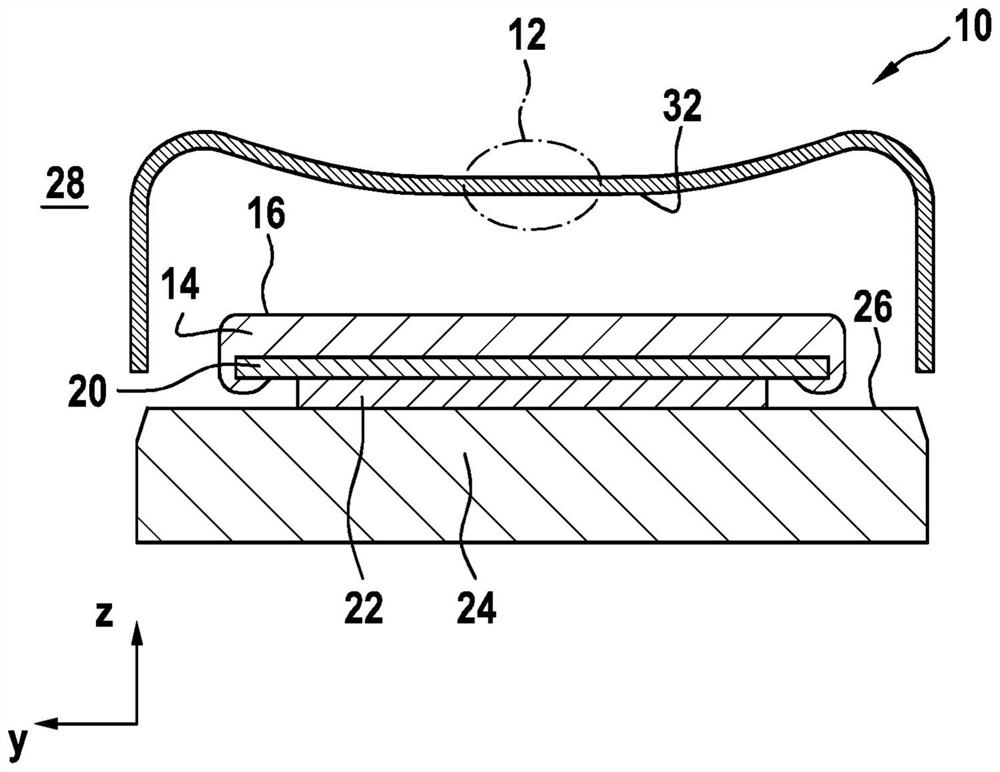

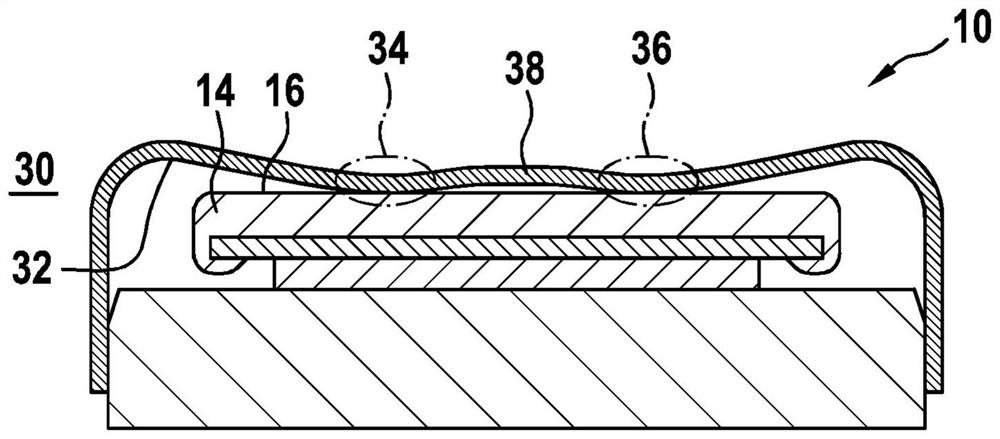

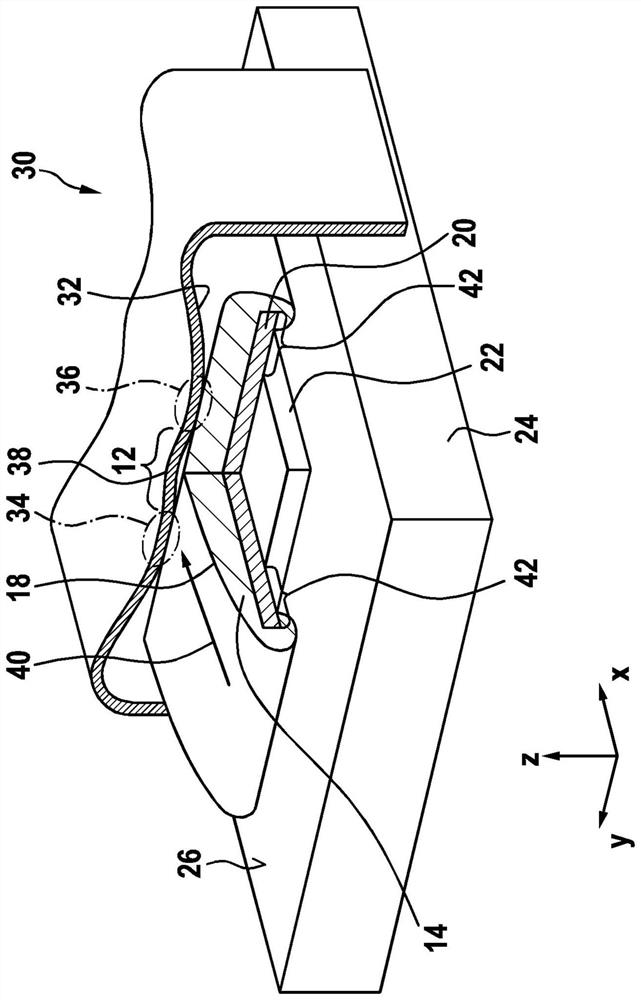

[0031] figure 1 The fastening device 10 proposed according to the invention is shown in its relaxed state 28 .

[0032] as by figure 1 It is known that the fastening device 10 proposed according to the invention is embodied, for example, as a spring clip and comprises a middle part 12 . The middle part 12 has a contact side 32 on the side facing the cover 14 . in accordance with figure 1 In the view of , the region of the contact side 32 of the middle part 12 is implemented straight. On both sides of the central part 12 , the first connecting plate 82 and the second connecting plate 84 of the fastening device 10 extend parallel to each other.

[0033] The fixing device 10 is arranged above the cover 14 . Cover 14 can have as figure 1 The flat upper side 16 shown in ; alternatively there is also the following possibility: According to image 3 A similar view of FIG. 10 implements the cover 14 with a curved upper side 18 . The cover 14 is manufactured from a plastic mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com