Aqueous composition, method for roughening stainless steel surface in which same is used, roughened stainless steel, and method for manufacturing same

A technology of water-based composition and treatment method, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., to achieve the effect of less number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

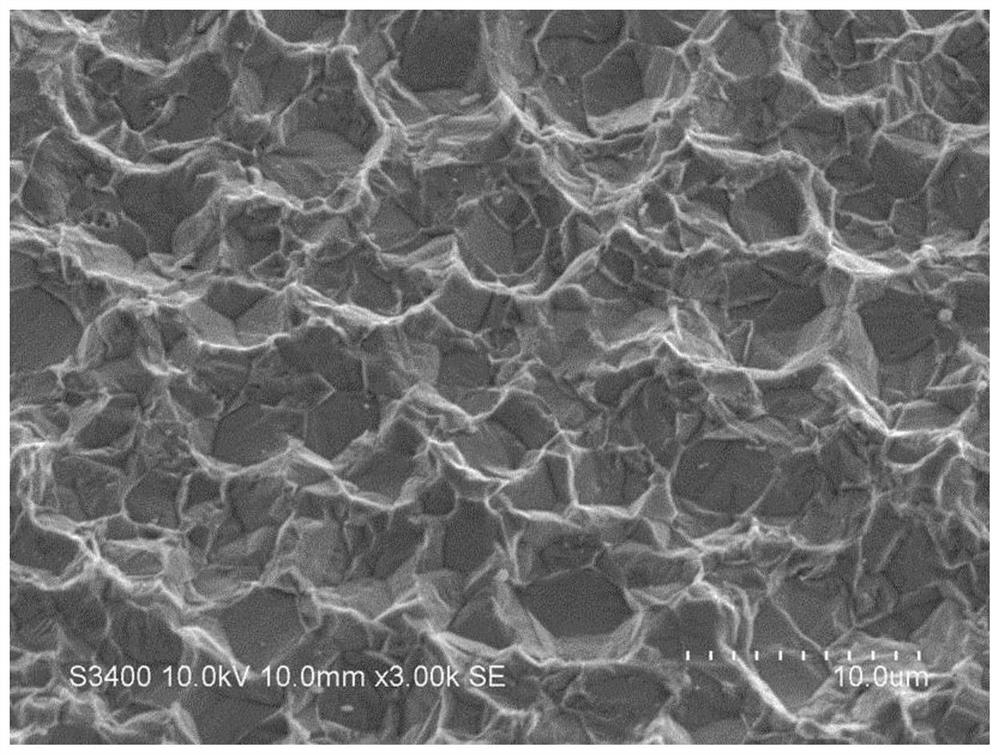

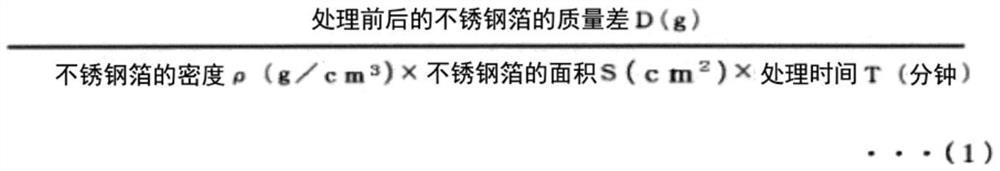

[0132] A stainless steel foil having a thickness of 20 μm, a vertical and horizontal length of 30 mm×30 mm, and a material of SUS304 was prepared. Rz of this stainless steel foil measured according to the said "measurement of surface roughness of stainless steel foil" was 1.2 micrometers, and Ra was 0.2 micrometers.

[0133] In the ultrapure water of 130ml, add the hydrogen peroxide of the amount (0.7g of 60wt% aqueous hydrogen peroxide solution) that finally forms 0.2 mass %, the copper sulfate pentahydrate of 6 mass % (12.0g), 29 mass % ( 57.1 g) of a 35 wt% aqueous solution of hydrochloric acid was prepared to prepare an aqueous composition. Copper ions (Cu 2+ ) concentration is 1.5% by mass based on the total amount of the aqueous composition, halide ions (Cl - ) concentration is 10% by mass based on the total amount of the aqueous composition.

[0134] First, the above-mentioned stainless steel foil was immersed in the above-mentioned aqueous composition at a liquid te...

Embodiment 2

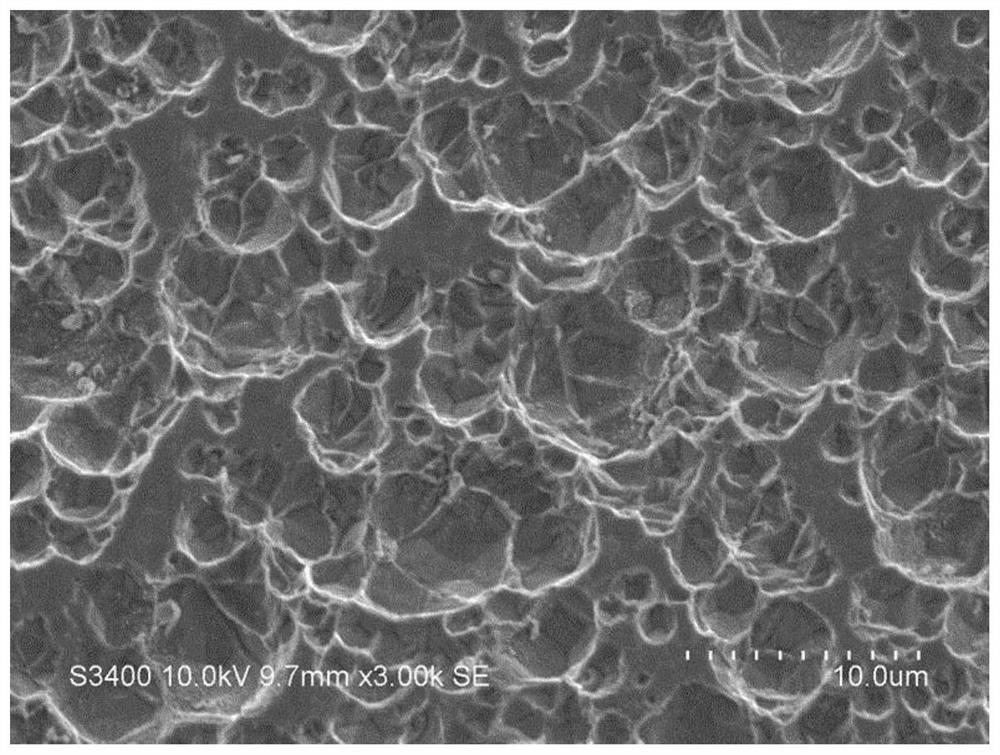

[0136] A stainless steel foil having a thickness of 20 μm, a vertical and horizontal length of 30 mm×30 mm, and a material of SUS304 was prepared.

[0137]In the ultrapure water of 124ml, add the hydrogen peroxide of the amount (60wt% hydrogen peroxide aqueous solution 6.7g) that finally forms 2 mass %, the copper sulfate pentahydrate of 6 mass % (12.0g), 29 mass % ( 57.1 g) of a 35 wt% aqueous solution of hydrochloric acid was prepared to prepare an aqueous composition. Copper ions (Cu 2+ ) concentration is 1.5% by mass based on the total amount of the aqueous composition, halide ions (Cl - ) concentration is 10% by mass based on the total amount of the aqueous composition.

[0138] First, the above-mentioned stainless steel foil was immersed in the above-mentioned aqueous composition at a liquid temperature of 40° C. for 60 seconds. Next, the dipped stainless steel foil was sufficiently washed with ultrapure water, and then sufficiently dried to obtain a surface-treated f...

Embodiment 3

[0140] A stainless steel foil having a thickness of 20 μm, a vertical and horizontal length of 30 mm×30 mm, and a material of SUS304 was prepared.

[0141] In the ultrapure water of 70ml, add the hydrogen peroxide of the amount (60wt% hydrogen peroxide aqueous solution 0.7g) that finally forms 0.2 mass %, the copper sulfate pentahydrate of 36 mass % (72.0g), 29 mass % ( 57.1 g) of a 35 wt% aqueous solution of hydrochloric acid was prepared to prepare an aqueous composition. Copper ions (Cu 2+ ) concentration is 9.0% by mass based on the total amount of the aqueous composition, derived from halide ions (Cl - ) concentration is 10% by mass based on the total amount of the aqueous composition.

[0142] First, the above-mentioned stainless steel foil was immersed in the above-mentioned aqueous composition at a liquid temperature of 40° C. for 60 seconds. Next, the dipped stainless steel foil was sufficiently washed with ultrapure water, and then sufficiently dried to obtain a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com