Metal organic framework crystal film for all-vanadium redox flow battery

A metal-organic framework and liquid flow battery technology, applied in fuel cells, regenerative fuel cells, circuits, etc., to achieve synchronous improvement of ion selectivity and mass transfer performance, and stable charge-discharge cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

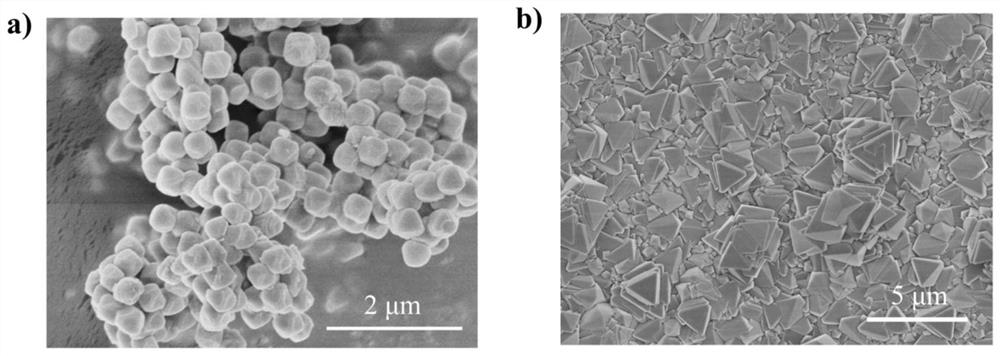

[0043] MOF-801 crystal synthesis: 3.20g ZrOCl 2 ·8H 2 O and 1.16g of fumaric acid were dissolved in a mixed solvent of DMF / formic acid (40mL / 14mL). After the solution was ultrasonically dissolved, the uniformly dispersed solution was slowly poured into the reactor, and the reactor was sealed and reacted at 130°C for 6h. Cool down after the reaction, take out the sample, wash it three times with DMF, wash it three times with methanol, and soak it in methanol solution for 3 days, and finally dry it in vacuum at 60°C for 24 hours, and collect the MOF-801 white powder ( figure 1 a)

[0044] MOF-808 crystal synthesis: 0.54g ZrOCl 2 ·8H 2 O and 0.11g of trimesic acid were dissolved in a mixed solvent of DMF / formic acid (25mL / 25mL). After the solution was ultrasonically dissolved, the uniformly dispersed solution was slowly poured into the reactor, and the reactor was sealed and reacted at 130°C for 48h. Cool down after the reaction, take out the sample, wash it three times with ...

Embodiment 2

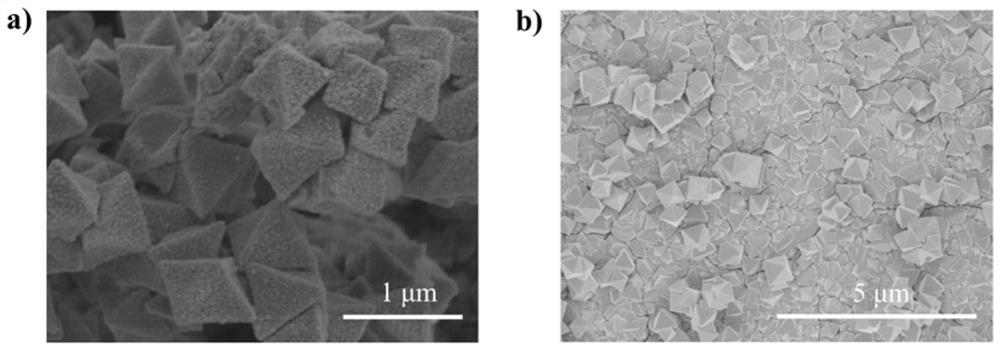

[0046] Preparation of MOF-801 membrane

[0047] Select 1mm porous α-Al 2 o 3 The ceramic sheet is used as a support, and it is pretreated before use: first, use the whole body and immerse it in concentrated hydrogen peroxide for 2 hours, take it out and rinse it with deionized water, put it into the reaction kettle, add a certain amount of deionized water, and heat it at 120°C , heated for 2 hours, and dried at 60°C for 12 hours after taking it out. Prepare 0.1wt% MOF-801 seed crystal solution. Then, using the dipping and pulling method, the side of the support surface pretreated was horizontally immersed in the seed liquid for 10 seconds, then dried at room temperature for 10 minutes, repeated 3 times, and placed in an oven at 60°C for 12 hours. Then the support (with the seed crystal side down) was horizontally fixed on the polytetrafluoroethylene support and placed at the bottom of the reactor. 3.20g ZrOCl 2 ·8H 2 O and 1.16g of fumaric acid were dissolved in a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com