Cable, fireproof and explosion-proof blanket and application thereof

A technology of explosion-proof cavity and fire-proof cavity, which is applied in the field of cables and fire-proof and explosion-proof blankets, can solve the problems of inability to install explosion-proof shells, threats to the personal safety of operators, and long distances between wells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] In some of the embodiments, the preparation method of the modified expandable graphite particles includes the following steps (1)-(3).

[0047] (1) Pulverize the expandable graphite, and then microwave the pulverized expandable graphite under 100W power for 20s-40s to obtain the primary product.

[0048] (2) The initial product, basic zinc carbonate and water are ultrasonically mixed, and then calcium carbonate powder is added to continue mixing to obtain a mixture.

[0049] (3) The mixture is centrifuged to obtain precipitates, and dried to obtain modified expandable graphite particles.

[0050] The basic zinc carbonate in the modified expandable graphite particles decomposes at high temperature to produce carbon dioxide and water, and the calcium carbonate decomposes at high temperature to produce carbon dioxide, which can further curb combustion and has good flame retardancy.

[0051] In some of these embodiments, the mass ratio of basic zinc carbonate to the primary ...

Embodiment 1

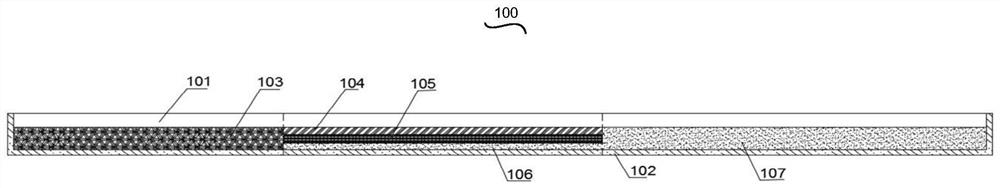

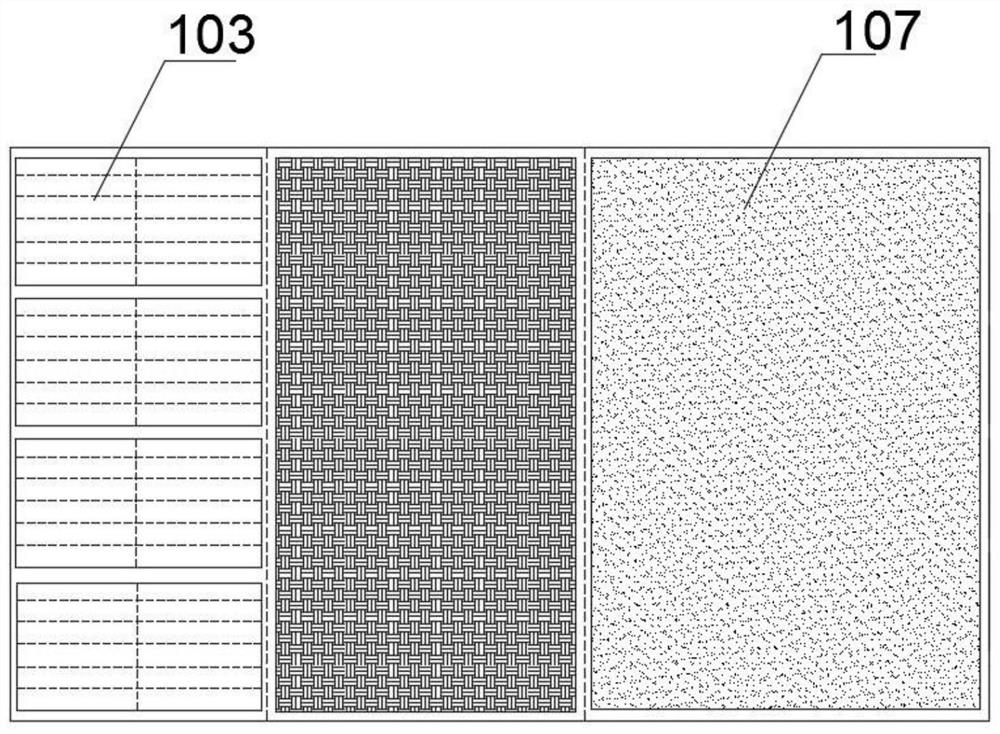

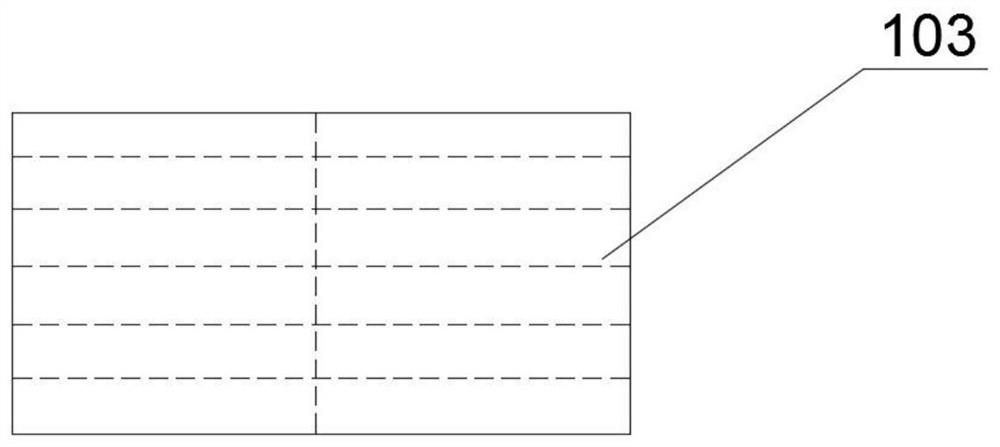

[0066] The fire-proof and explosion-proof blanket of this embodiment includes a blanket main body 100 and a fastening component for wrapping the fire-proof and explosion-proof blanket at the high-voltage cable joint. The blanket body includes an insulating layer 101 and a basalt fiber layer 102, the insulating layer 101 and the insulating layer 101 and the basalt fiber layer 102 are respectively the upper surface and the lower surface of the blanket main body 100, and the side of the basalt fiber layer 102 is connected to the side of the insulating layer 101. The edges are wrapped and connected, and an interlayer cavity is formed between the insulating layer 101 and the basalt fiber layer 102, and the interlayer cavity is divided into a fireproof cavity, an explosion-proof cavity and a buffer cavity by sewing lines. The fireproof cavity, explosion-proof cavity and buffer cavity are wrapped in the high-voltage cable joint in turn, and the width of the fireproof cavity, explosion...

Embodiment 2

[0074] The fire and explosion-proof blanket of this embodiment is basically the same as that of Embodiment 1, except that the mass ratio of the expandable graphite particles to the modified expandable graphite particles in the expandable graphite bag 103 is different, and the preparation method of the modified expandable graphite particles is different.

[0075] The fire-proof and explosion-proof blanket of this embodiment includes a blanket main body 100 and a fastening component for wrapping the fire-proof and explosion-proof blanket at the high-voltage cable joint. The fire and explosion-proof blanket body includes an insulating layer 101 and a basalt fiber layer 102. The insulating layer 101, the insulating layer 101 and the basalt fiber layer 102 are the upper surface and the lower surface of the blanket main body 100, respectively, and the sides of the basalt fiber layer 102 cover the insulating layer 101. The sides of the insulation layer 101 and the basalt fiber layer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com