Movable semi-automatic internal thread detection device

A detection device and internal thread technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problems of high labor intensity, large production batch, low efficiency, etc., to reduce labor intensity, effectively screw, improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

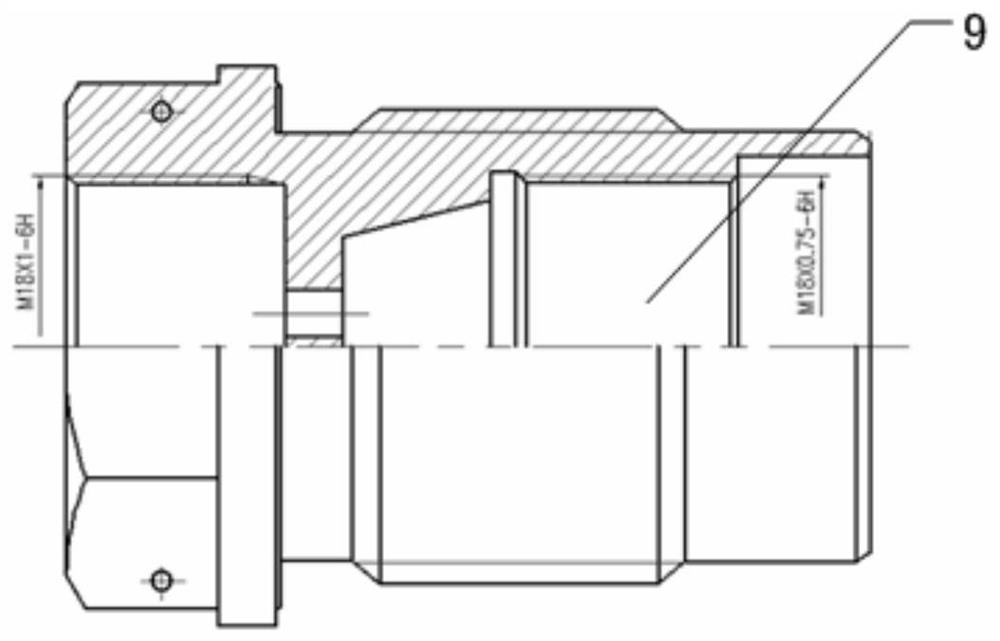

Image

Examples

Embodiment Construction

[0044] Thread detection is a process in which internal and external threads are screwed together. Due to the use of an automatic device for screwing, the coordination flexibility is reduced compared to hands, so the device also needs to seek a reliable flexible matching structure; thread detection is a qualitative detection process. If quantitative digital detection can be realized, the reliability and traceability of thread detection will also be improved.

[0045] The present invention is a semi-automatic detection device for movable internal thread, such as figure 1 As shown, it includes: a device detection platform 1, a control system 2, a display and an input and output device 3, a fixed column 4, a pneumatic suspension arm 5, a thread detection mechanism 6, a platform moving pulley 8 and a connecting piece 7.

[0046] The fixed column 4 is fixedly installed on the upper surface of the device detection platform 1, and the fixed column 4, the pneumatic suspension arm 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com