Blasting dust-proof device

A technology of dust-proof device and dust-proof cover, which is applied in the field of blasting and can solve the problems affecting the physical and mental health of workers and easy to absorb dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

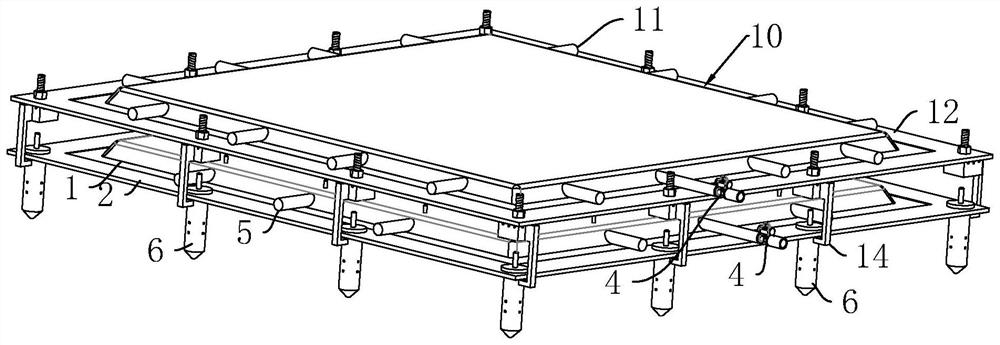

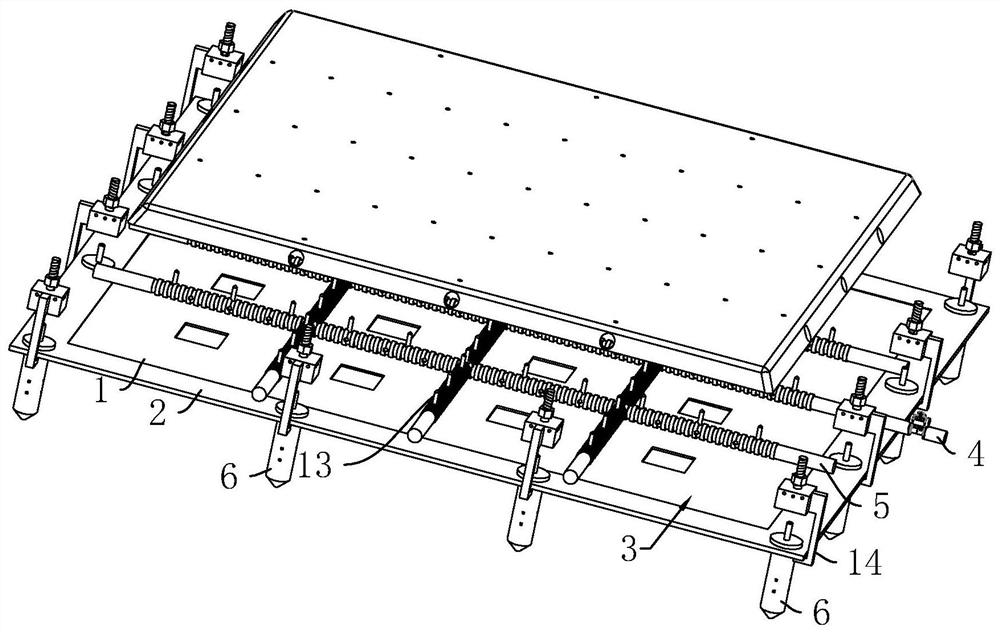

[0037] The following is attached Figure 1-5 The application is described in further detail.

[0038] The embodiment of the present application discloses a blasting dust prevention device. refer to figure 1 , including the dust cover 1 covering the ground to be blasted, the edge of the dust cover 1 is bonded with a reinforcement strip 2 surrounding the dust cover 1, and the reinforcement strip 2 is connected with a plug for fixing the dust cover 1 on the ground. pick up.

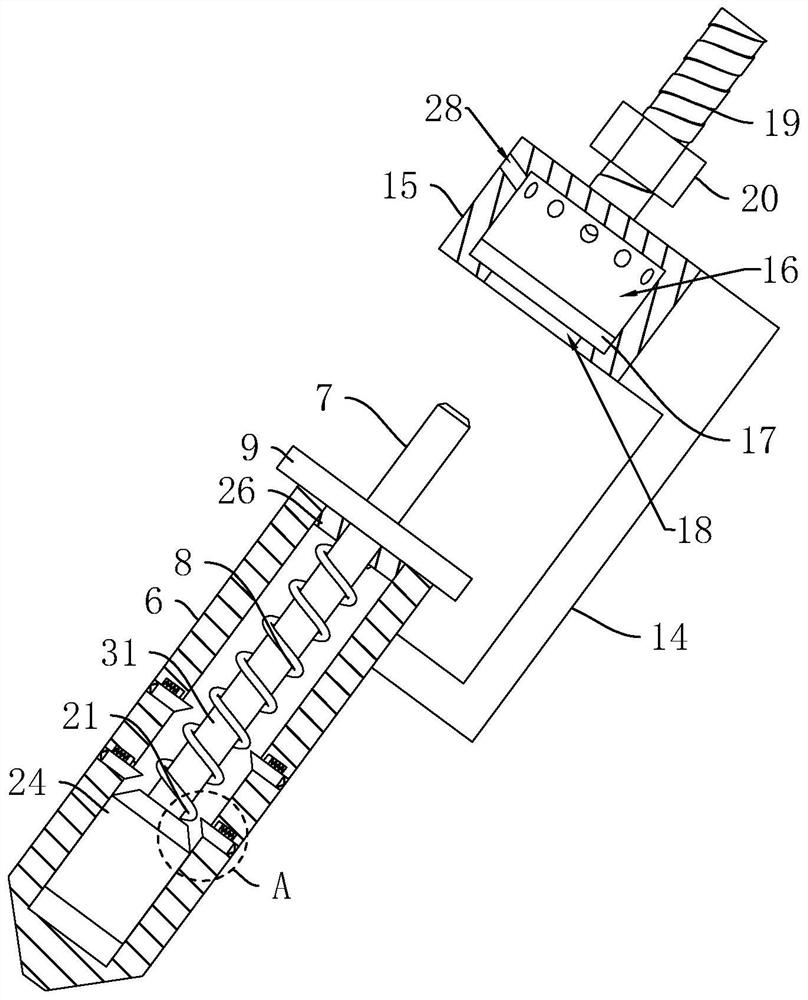

[0039] refer to figure 1 and figure 2 , the dust cover 1 comprises two layers of plastic film up and down, and the upper and lower two layers of plastic film are heat-pressed or bonded to form a number of hollow water collection bags 3 between the two layers of plastic film. A water injection pipe 5 is arranged at the junction, and two layers of plastic films are sealed and adhered to the outer wall of the water injection pipe 5. The water injection pipe 5 includes a straight pipe with rubber at both e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com