#-shaped modular splicing truss for fabricated steel structure

A steel structure and well-shaped technology, which is applied in the direction of load-bearing elongated structural members, truss structures, structural elements, etc., can solve the problems of high transportation costs and difficult assembly, and achieve good stability and safety margins The effect of high and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: This embodiment aims to provide a well-shaped modular splicing truss for prefabricated steel structures, which is mainly used for prefabricated steel truss structures. It is a new type of steel that can be modularized and quickly assembled. Structural truss beams can speed up the assembly efficiency of prefabricated steel structure buildings, reduce transportation and construction costs, and facilitate on-site construction and installation, providing new design ideas and construction solutions for prefabricated steel structure building systems.

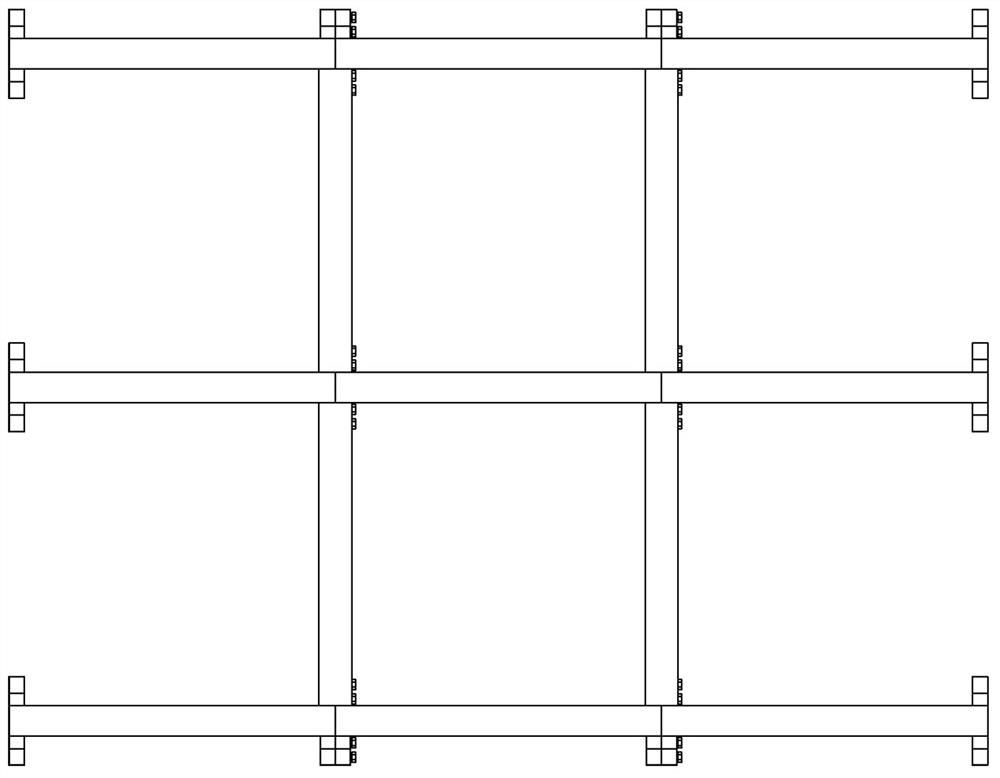

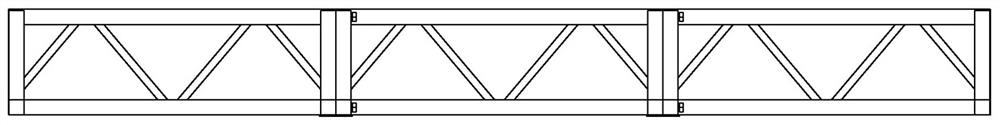

[0039] In a specific structure, such as Figure 1-4 As shown in , a well-shaped modular splicing truss for prefabricated steel structures, including a splicing unit 1 and a connecting unit 2; where the side of the splicing unit 1 can be connected with the splicing unit 1 at the same level, and both ends pass through The connecting unit 2 is connected with another longitudinal splicing unit 1 to form a splicing tru...

Embodiment 2

[0046] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is that this embodiment further explains the specific structure of the connection hole.

[0047] In this example, if Figure 5 As shown in , the connection holes include inner holes, outer holes and mounting holes; the inner holes are located in the middle and correspond to the middle of the upper main chord and the lower main chord, and the outer holes are located in the outer for connecting splicing units from the outside , the mounting hole is used to install the connecting rod.

[0048] During the installation process, the internal hole is located inside, and it is difficult for construction personnel to operate on site. For this purpose, in this embodiment, a conjoined reinforcing plate 6 is provided on the outside of the internal hole, the external hole and the installation hole.

[0049] Such as Figure 15 As shown in , the middle part of the reinforcing plate 6 is provided with...

Embodiment 3

[0051] Embodiment 3: This embodiment is basically the same as Embodiment 1, and the difference is that this embodiment is provided with a reinforced isolation component.

[0052] In this example, if Figure 8 As shown in , the openings of the upper node chord 11 and the lower node chord 14 are matched with a reinforced isolation assembly 4, and the reinforced isolation assembly 4 includes a top plate 41, a partition 42 and a sleeve 43, and the partitions 42 are arranged vertically at intervals At the bottom of the top plate 41, a plurality of splicing bolt partitions are formed, and a sleeve 43 is fixed in each splicing bolt partition. The sleeve 43 corresponds to the connecting hole, and horizontal lines 64 are arranged between the round holes to increase the contact friction. force.

[0053] This embodiment aims to strengthen the connection structure, further increase the maximum applied strength of the splicing bolts, increase the bearing range of the upper node chord and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com