Liftable grid plate installed on flocculation basin

A technology of grid plate and flocculation tank, which is applied in the field of lifting grid plate, can solve the problems that the grid plate of the flocculation tank is difficult to clean and maintain, small alum flowers cannot be gathered, and manual operation is difficult, so as to reduce labor input and improve Safety and reliability, the effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

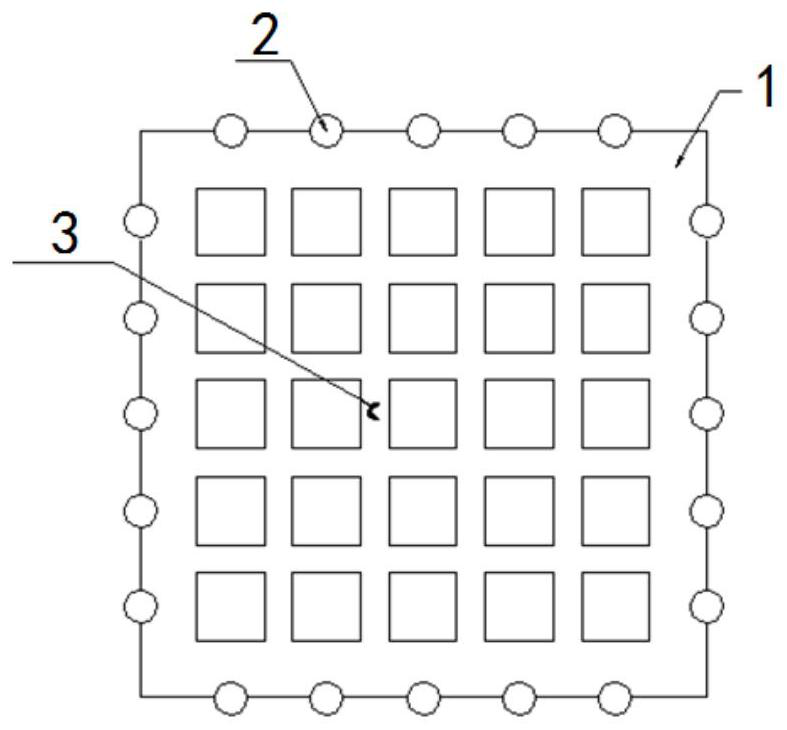

[0029] A liftable grid plate installed in a flocculation tank, such as Figures 1 to 2 As shown in the figure, it includes a grid plate body 1, a roller 2 and a traction rope 3. The grid plate body 1 and the roller 2 are integrally connected, and the grid plate bodies 1 in the same shaft 4 are connected to each other through a traction rope 3, and one end of the traction rope 3 is connected to each other. It is fixed to the grid board body 1, and the other end is connected to the traction device.

[0030] When cleaning is required, the traction device pulls the traction rope 3, and the grid plate body 1 is lifted to the top of the shaft 4 under the action of the traction rope 3 through the action of the roller 2. Take out the grid plate body 1 in the shaft 4 one by one, clean the grid plate body 1, and pull the traction rope 3 to return the grid plate body 1 to the shaft 4 under the action of the roller 2 and the grid plate body 1's own gravity, and clean it. The process is c...

Embodiment 2

[0032] A liftable grid plate installed in a flocculation tank, each grid plate body 1 is surrounded by a plurality of rollers 2, and the rollers 2 are symmetrically arranged on the grid plate body 1, which can improve the stability of the traction process. The rest of the structure is the same as that of Example 1.

Embodiment 3

[0034] A liftable grid plate installed in a flocculation tank, and a guide structure for guiding the up and down movement of the roller 2 is vertically arranged on the inner side of the shaft 4 . The rest of the structure is the same as that of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com