Multi-layer sandwich and locally-reinforced external heat-proof material as well as preparation method and application thereof

A local enhancement and heat-proof technology, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of high assembly precision, high cost, and many processes involved, achieve fast production, reduce processes and costs , The effect of avoiding shedding and air leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

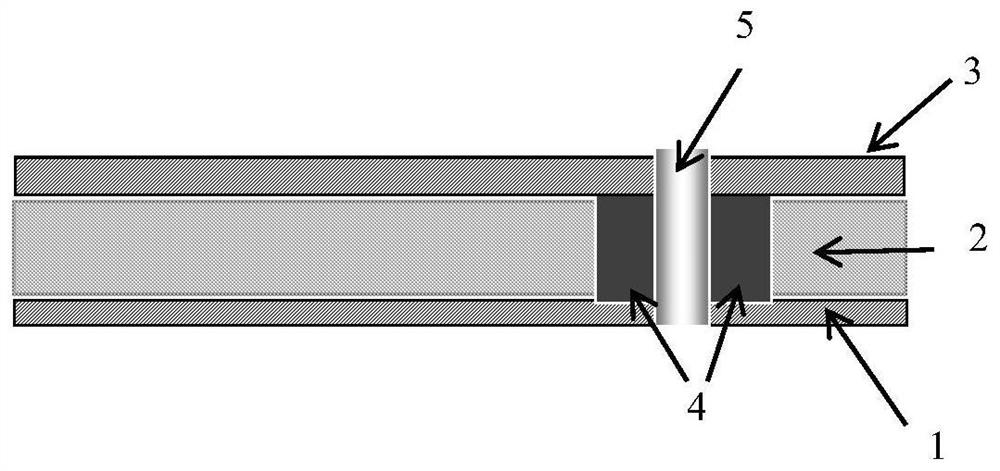

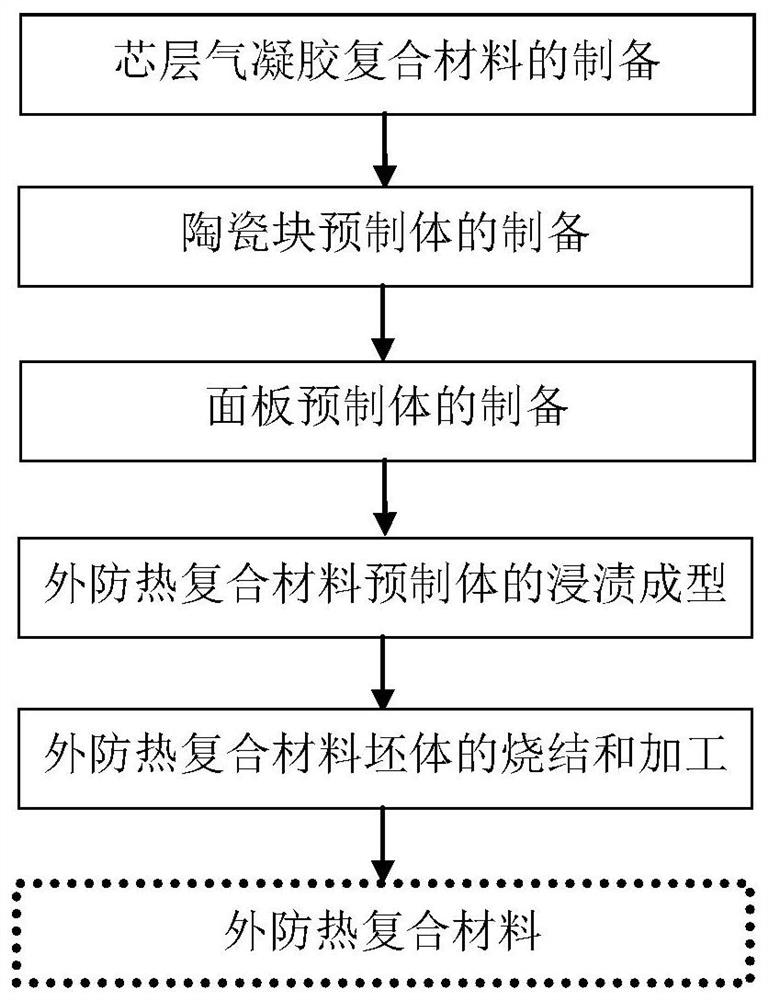

[0025] As mentioned above, the first aspect of the present invention provides a method for preparing a multi-layer sandwich and partially reinforced external heat-resistant composite material. The external heat-resistant composite material includes a first panel, a second panel, a An airgel core layer between the second panels; the outer heat-resistant composite material has a non-reinforced area and a locally reinforced area formed by a ceramic block, and the preparation method includes the following steps:

[0026] (1) Preparation of the core layer airgel composite material for forming the airgel core layer: according to the target thickness and target shape, prepare the core layer airgel composite material and process the local area to be reinforced;

[0027] (2) Preparation of the ceramic block prefabricated body for forming the ceramic block: the fiber fabric is laminated to the target thickness according to the predetermined thickness tolerance, and then sewed, and then c...

Embodiment 1

[0070] According to the target shape and target size (arc with arc length 300mm and width 300mm) of the outer heat-resistant material, an outer heat-resistant composite material with a locally reinforced ceramic ring (80mm in diameter) is prepared, and the ceramic convex altar has a diameter of 30mm round hole.

[0071] The preparation method of the outer heat-resistant composite material comprises the following steps:

[0072] First, the airgel core layer is prepared by using an airgel forming mold, that is, the mullite fiber felt is cut according to the cavity of the airgel forming model, and then the mold is closed, and 25% of the silicon precursor sol is injected into the mold to make the glue solution completely Impregnate the fiber matrix, undergo aging, solvent replacement, supercritical drying, and hydrophobic treatment to obtain a core layer airgel composite material with a thickness of 10 mm (sometimes called an airgel core layer).

[0073] According to the target s...

Embodiment 2

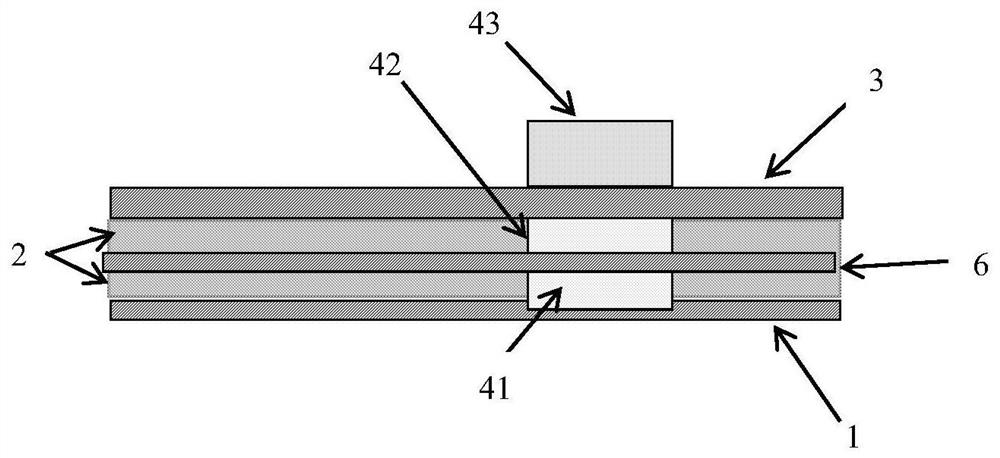

[0080] According to the target shape and target size of the outer heat-resistant material (circular boss with a diameter of 100mm, the thickness of the non-reinforced area is 15mm, the thickness of the reinforced area (boss area) is 30mm, the reinforced boss type, the size of the outer heat-resistant material 300mm × 300mm) to prepare an outer heat-resistant composite material with a 3-layer sandwich and partially a circular boss-shaped ceramic block. Such as figure 2 As shown, the ceramic block is divided into three parts by the second panel and the middle panel to form a circular boss type ceramic block. The ceramic block 43 is located on the second panel with a thickness of 15mm. The ceramic block 42 is between the second panel and the middle panel. , the thickness is 6mm, the ceramic block 41 is the ceramic block between the middle panel and the first panel, and the thickness is 6mm.

[0081] The preparation method of the outer heat-resistant composite material comprises...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com