A micro-nano textured guide rail and method based on ultrasonic rolling and femtosecond laser processing

A technology of femtosecond laser processing and ultrasonic rolling, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of strained processing surface, raised slag, and aggravated wear, so as to improve the processing quality and precision, facilitate flow and extrusion, improve tribological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

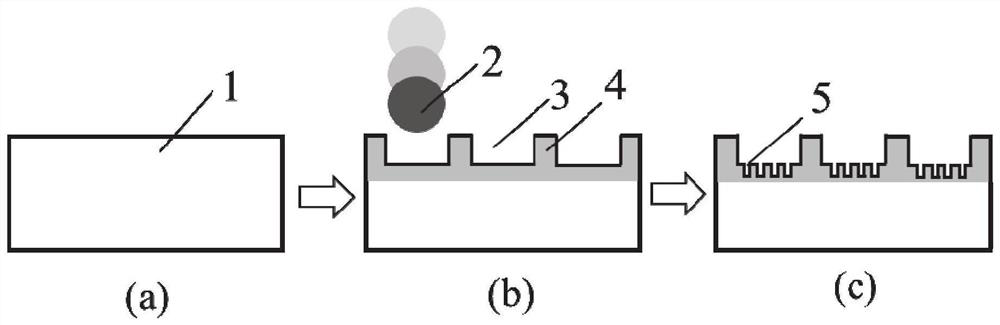

[0033] In a typical embodiment of the present disclosure, as Figure 1-Figure 4 As shown, a micro-nano textured guide rail based on ultrasonic rolling and femtosecond laser processing is presented.

[0034] Aiming at the problem that the surface texture of the guide rail base 1 is difficult to meet the sliding requirements of the machine tool, a micro-nano textured guide rail based on ultrasonic rolling and femtosecond laser processing is provided. Micro-textured groove 3, and then use femtosecond laser to process nano-textured groove 5 on the bottom surface of micro-textured groove 3 to realize the preparation of micro-nano composite textured guide rail, thereby improving the tribological performance of the guide rail and prolonging the service life of the guide rail life.

[0035] The micro-nano textured guide rail based on ultrasonic rolling and femtosecond laser processing includes a guide rail base 1, and the surface of the guide rail base 1 is processed. The surface of ...

Embodiment 2

[0051] In another embodiment of the present disclosure, as Figure 1-Figure 4 As shown, a method for fabricating micro-nano textured rails based on ultrasonic rolling and femtosecond laser processing is presented.

[0052] The grid-like micro-texture grooves 3 are ultrasonically rolled on the surface of the guide rail base 1 by using the ultrasonic rolling technology, and then uniformly distributed nano-texture grooves are processed inside the grid-like micro-texture grooves 3 by the femtosecond laser technology. 5. Realize the preparation of micro-nano composite textured guide rails.

[0053] Specifically, as figure 1 As shown, the method for preparing the micro-nano composite textured guide rail based on ultrasonic rolling and femtosecond laser processing includes the following steps:

[0054] Ultrasonic cleaning and drying of the surface of the guide rail base 1;

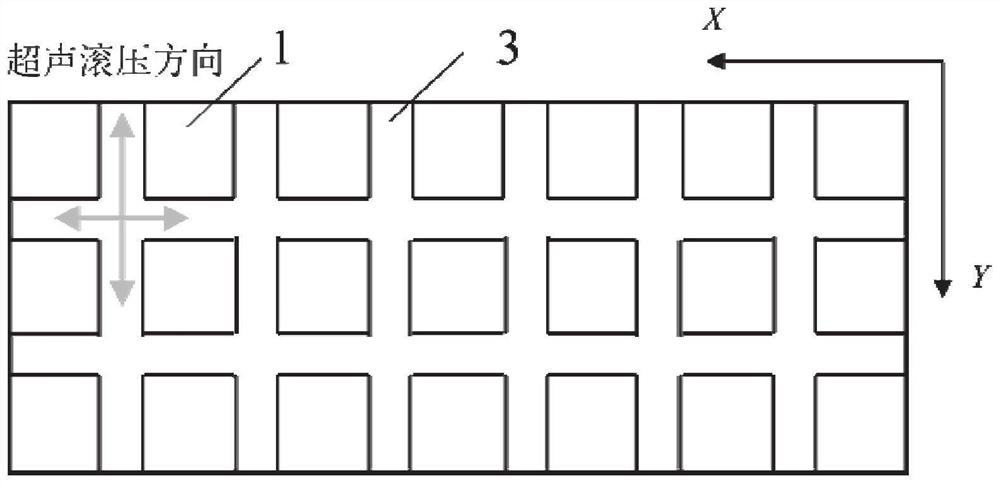

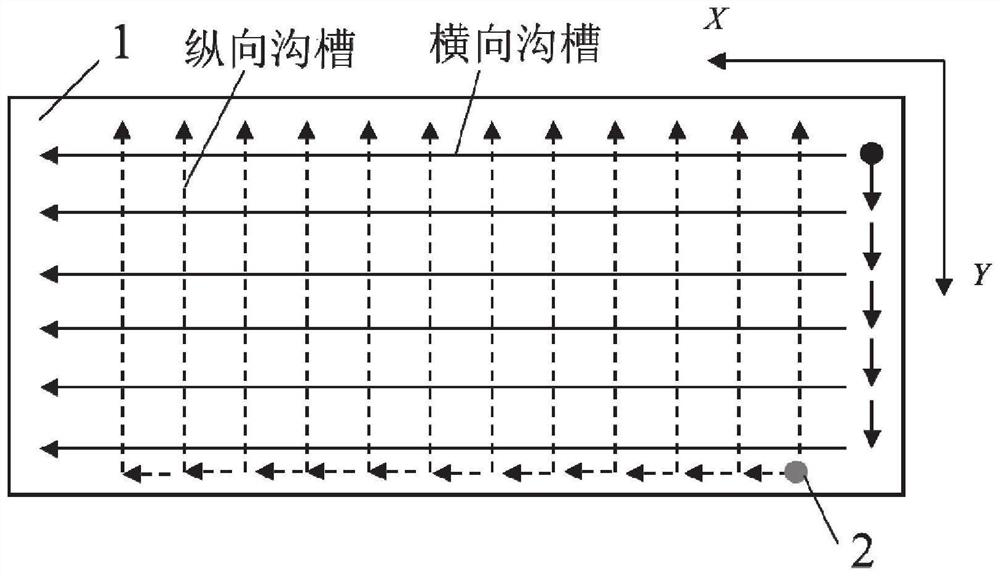

[0055] like figure 2 , image 3 As shown, by changing the ultrasonic rolling processing parameters and p...

Embodiment 3

[0067] In yet another embodiment of the present disclosure, as Figure 1-Figure 4 As shown, a method for preparing a micro-nano textured guide rail based on ultrasonic rolling and femtosecond laser processing is given. The difference from Example 2 lies in the material of the guide rail matrix 1 and the processing process of the micro-nano composite texture.

[0068] The guide rail base body 1 is made of 40Cr steel, and the initial hardness of the guide rail base body 1 is 220HB.

[0069] like Figure 1-Figure 4 As shown, the grid-like micro-textured grooves 3 are processed on the surface of the guide rail substrate 1 by ultrasonic rolling technology, and the two sides of the grid-like micro-textured grooves 3 are respectively parallel and perpendicular to the sliding direction of the guide rail. The parameters are static pressure of 1200N, amplitude of 8μm, feed rate of 2000mm / min, processing step distance of 0.25mm, rolling times of 1 time, and rolling ball diameter of 6mm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com