Preparation and application of hollow zirconium-based porphyrin type metal organic framework solid-phase microextraction fiber

A metal-organic framework and zirconium-based porphyrin-based technology, applied in fiber treatment, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as single microporous structure, difficult macromolecules, mass transfer limitations, etc. , to achieve the effect of fast mass transfer rate, high utilization of specific surface area, and overcoming thermal instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Preparation of polydopamine-modified stainless steel fibers:

[0030] a. Soak the 3cm-long end of the stainless steel fiber in hydrofluoric acid at 70°C for 15 minutes, then ultrasonically clean it with pure water to obtain a stainless steel fiber with a rough surface at one end, and dry it for later use;

[0031] b. Put the treated end of the stainless steel fiber in 2 mg·mL -1 Dopamine aqueous solution, and adjust its pH value to 8.5 with Tris-HCl solution, and leave it at room temperature for 24 h to obtain PDA-modified stainless steel fibers;

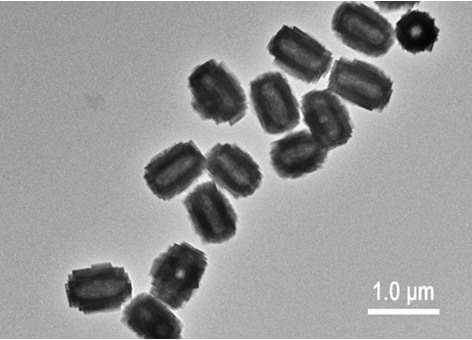

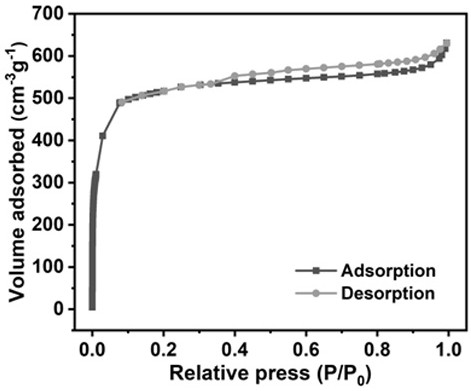

[0032] 2) Preparation of HZP-MOFs solid-phase microextraction fibers:

[0033] c. Dissolve 10 mg zirconium chloride, 200 mg benzoic acid and 200 μl water in 2 mL DMF, stir at room temperature for 5 minutes, then add 10 mg TCCP, and continue stirring for 10 minutes to obtain a homogeneous solution;

[0034] d. Transfer the obtained homogeneous solution to a 12 mL autoclave, immerse the prepared polydopamine-modified stain...

Embodiment 2

[0039] 1) Preparation of polydopamine-modified stainless steel fibers:

[0040] a. Soak the 3cm-long end of the stainless steel fiber in hydrofluoric acid at 70°C for 15 minutes, then ultrasonically clean it with pure water to obtain a stainless steel fiber with a rough surface at one end, and dry it for later use;

[0041] b. Put the treated end of the stainless steel fiber in 2 mg·mL -1 Dopamine aqueous solution, and adjust its pH value to 8.5 with Tris-HCl solution, and leave it at room temperature for 24 h to obtain PDA-modified stainless steel fibers;

[0042] 2) Preparation of HZP-MOFs solid-phase microextraction fibers:

[0043] c. Dissolve 10 mg zirconium chloride, 250 mg benzoic acid and 200 μl water in 2 mL DMF, stir at room temperature for 5 minutes, then add 10 mg TCCP, and continue stirring for 10 minutes to obtain a homogeneous solution;

[0044] d. Transfer the obtained homogeneous solution to a 12 mL autoclave, immerse the prepared polydopamine-modified stain...

Embodiment 3

[0046] 1) Preparation of polydopamine-modified stainless steel fibers:

[0047] a. Soak the 3cm-long end of the stainless steel fiber in hydrofluoric acid at 70°C for 15 minutes, then ultrasonically clean it with pure water to obtain a stainless steel fiber with a rough surface at one end, and dry it for later use;

[0048] b. Put the treated end of the stainless steel fiber in 2 mg·mL -1 Dopamine aqueous solution, and adjust its pH value to 8.5 with Tris-HCl solution, and leave it at room temperature for 24 h to obtain PDA-modified stainless steel fibers;

[0049] 2) Preparation of HZP-MOFs solid-phase microextraction fibers:

[0050] c. Dissolve 10 mg of zirconium chloride, 300 mg of benzoic acid and 200 μl of water in 2 mL of DMF, stir at room temperature for 5 minutes, then add 10 mg of TCCP, and continue stirring for 10 minutes to obtain a homogeneous solution;

[0051] d. Transfer the obtained homogeneous solution to a 12 mL autoclave, immerse the prepared polydopamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com