A kind of enzyme-responsive insecticidal slow-release agent and preparation method thereof

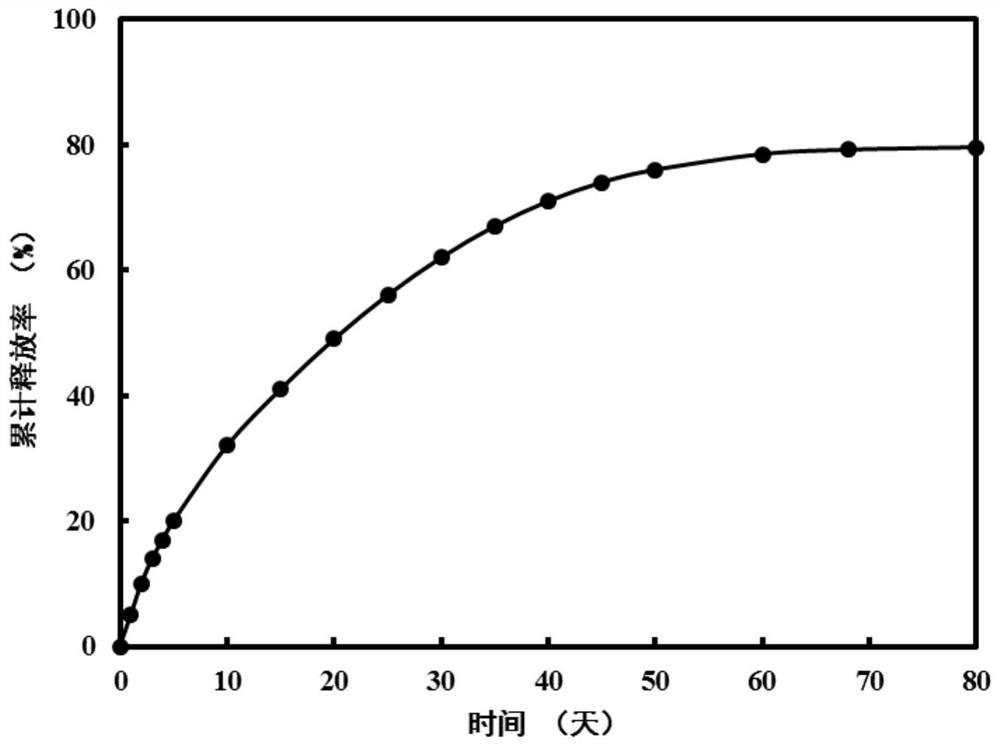

An enzyme-responsive, sustained-release agent technology, applied in the field of new formulations of pesticides, to achieve the effects of delayed release, loss prevention, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Add 2.5g polystyrene nanospheres, 2mL ammonia water, 9.6g deionized water, 0.80g cetyltrimethylammonium bromide (CTAB) and 11.0g ethanol to the flask, ultrasonically disperse for half an hour, turn on Stir for 30 minutes, add 1.5 g of ethyl orthosilicate to the above reaction system, and react for 48 hours at room temperature;

[0041] (2) Calcining the product in a muffle furnace at 600°C for 8 hours to obtain hollow nano-silica A;

[0042] (3) Add toluene and 1.0 g of hollow nano-silica A obtained in step (2) to the three-necked flask, ultrasonically disperse for half an hour and control the reaction temperature at 110° C., add dropwise 0.3 g of anilinomethyltriethoxysilane, React for 20 hours, centrifuge to remove the supernatant, wash the obtained solid, and repeat three times to obtain aniline-modified hollow nano-silica B;

[0043] (4) Add the obtained aniline-modified hollow nano-silica B and cyantraniliprole N,N-dimethylformamide solution into the flask, an...

Embodiment 2

[0051] (1) Add 2.5g polystyrene nanospheres, 4.0mL ammonia water, 19.2g deionized water, 1.6g cetyltrimethylammonium bromide (CTAB) and 22.0g ethanol to the flask, and ultrasonically disperse for half an hour. Start stirring for 30 minutes, add 1.5 g of ethyl orthosilicate to the above reaction system, and react for 60 hours at room temperature;

[0052] (2) Calcining the product in a muffle furnace at 600°C for 8 hours to obtain hollow nano-silica A;

[0053] (3) Add toluene and 1.0 g of hollow nano-silica A obtained in step (2) to the three-necked flask, ultrasonically disperse for half an hour and control the reaction temperature at 100° C., dropwise add 0.4 g of anilinomethyltriethoxysilane, React for 24 hours, centrifuge to remove the supernatant, wash the obtained solid, and repeat three times to obtain aniline-modified hollow nano-silica B;

[0054] (4) Add the obtained aniline-modified hollow nano-silica B, chlorantraniliprole N,N-dimethylformamide solution into the f...

Embodiment 3

[0061] (1) Add 2.5g polystyrene nanospheres, 1mL ammonia water, 4.8g deionized water, 0.40g cetyltrimethylammonium bromide (CTAB) and 5.5g ethanol to the flask, ultrasonically disperse for half an hour, and turn on Stir for 30 minutes, add 1.5 g of ethyl orthosilicate to the above reaction system, and react for 48 hours at room temperature;

[0062] (2) Calcining the product in a muffle furnace at 600°C for 8 hours to obtain hollow nano-silica A;

[0063] (3) Add toluene and 1.0 g of hollow nano-silica A obtained in step (2) to the three-necked flask, ultrasonically disperse for half an hour and control the reaction temperature at 90° C., dropwise add 0.3 g of anilinomethyltriethoxysilane, React for 24 hours, centrifuge to remove the supernatant, wash the obtained solid, and repeat three times to obtain aniline-modified hollow nano-silica B;

[0064] (4) Add the obtained aniline-modified hollow nano-silica B and cyantraniliprole N,N-dimethylformamide solution into the flask, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com