Laser detection system for visually measuring film stress

A thin-film stress, laser detection technology, applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve the problems of cumbersome inspection process and low accuracy, and achieve cumbersome process, high measurement accuracy and maintenance. high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

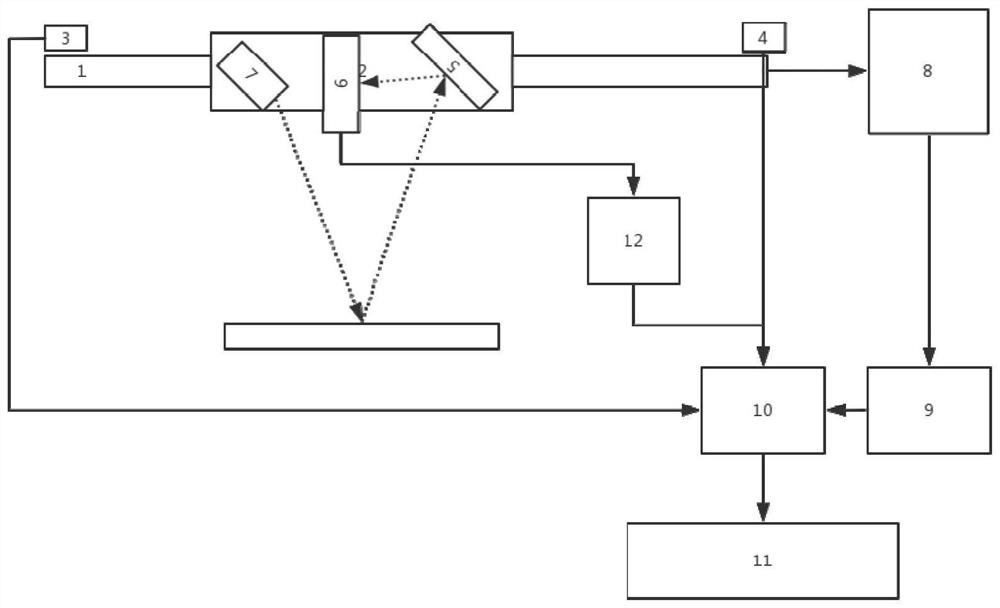

[0062] A visual laser measurement film stress detection system, including:

[0063] A laser measurement module, the laser measurement module at least includes a one-dimensional linear sensor 6, the laser measurement module is configured to emit laser light to the surface of the wafer and irradiate the laser reflected by the wafer onto the one-dimensional linear sensor 6;

[0064] In this embodiment, the laser measurement module is the basis for realizing the measurement of the film stress. In terms of specific design, the laser measurement module includes:

[0065] The laser 7 is used to emit laser light of a certain wavelength and irradiate the surface of the wafer;

[0066] The mirror 5 is used to conduct the laser light reflected from the surface of the wafer;

[0067] Driven by the one-dimensional screw rod carrying platform, the laser 7 passes the center point of the wafer and makes a one-dimensional movement along the diameter of the wafer. After the laser light of a c...

Embodiment 2

[0088] It is basically the same as Example 1. It can be seen from Embodiment 1 that, for the main control terminal, the main control terminal is configured to calculate the stress data of the wafer film according to the current change at both ends of the light curtain on the one-dimensional linear sensor, and generate a visualization based on the stress data of the wafer film Order. Therefore, for the main control terminal, how to calculate the stress data of the wafer film according to the current change at both ends of the light curtain on the one-dimensional linear sensor is a technical problem to be solved urgently in this embodiment. Based on this, further, the main control terminal is configured to calculate the stress data of the wafer film according to the current change at both ends of the light curtain on the one-dimensional linear sensor, including:

[0089] S1. Convert the upper current and lower current at both ends of the upper light curtain of the one-dimension...

Embodiment 3

[0105] It is basically the same as Example 2. In order to know more intuitively the unevenness of the wafer surface and to visualize the unevenness of the wafer surface, we need to know the curvature of the wafer film on each acquisition. Therefore in this embodiment, further, also include:

[0106] According to the stress data of the wafer film, take the center point of the wafer as the warp center, extend the distribution to the left and right of the center point, and establish the distribution relationship of the curvature of the wafer film.

[0107] It specifically includes:

[0108] The distribution relationship of the curvature of the wafer center point to the left is:

[0109] The distribution relationship of the rightward curvature of the wafer center point is:

[0110] In the above formula, B is the curvature of the current point, B i-1 is the curvature of the previous point, and d is the distance between two adjacent points of the collection point on the wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com