High-strength steel cord verticality detection device

A detection device and verticality technology, applied in the field of steel cord testing, can solve problems such as poor straightness of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] It should be noted that if there is a directional indication (such as up, down, left, right, front, back...) in the embodiment of the present invention, it is only used to explain the relationship between the components in a certain posture. If the specific posture changes, the directional indication will also change accordingly.

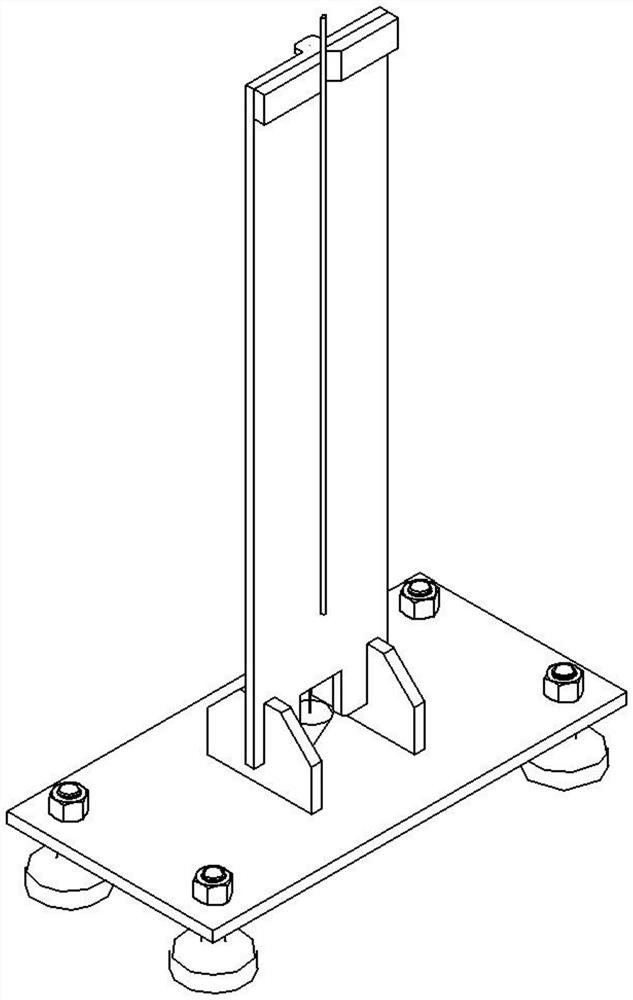

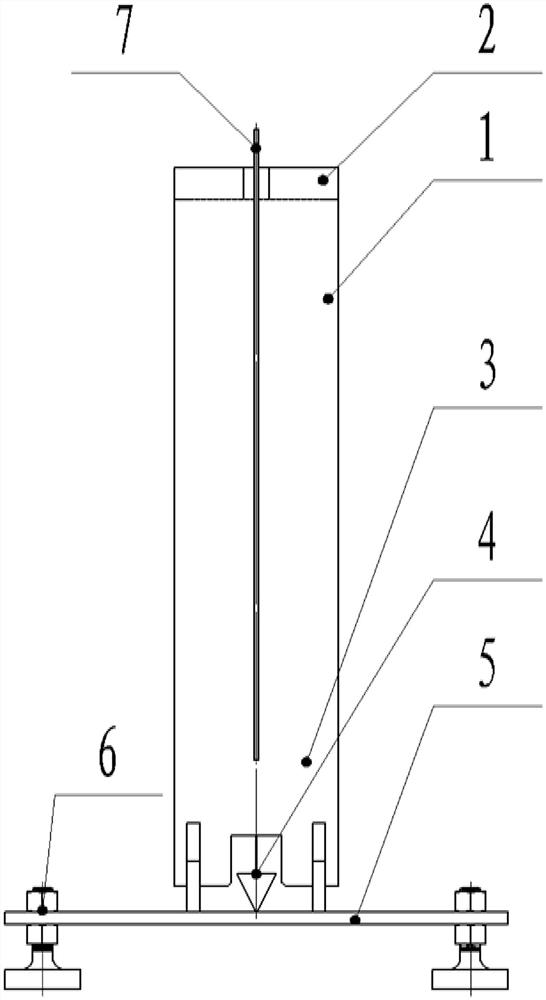

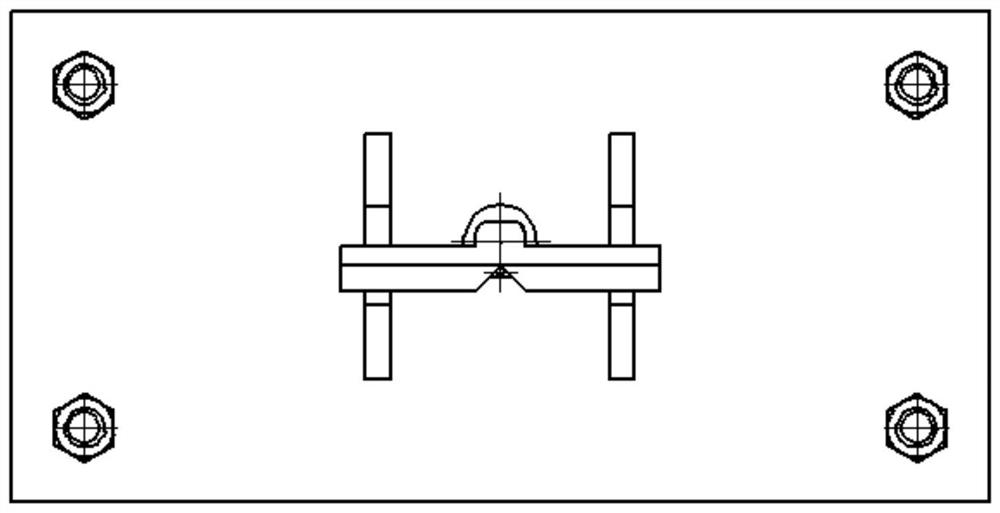

[0024] This device provides a detection device for the verticality of steel cords, which mainly includes a detection panel 1, a scale bar 3, a limit groove 2, a heavy vertical line 4, a fixed base 5 and an adjustment screw 6,

[0025] The detection panel 1 is a plexiglass panel or other non-magnetic material panel with a smooth and flat surface;

[0026] The scale bar 3 is on the surface of the detection panel 1, the total length of the scale bar 3 is 1m, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com