Locking bolt with elastic quick release mechanism

A locking bolt, elastic technology, applied in the direction of bolts, locking fasteners, screws, etc., can solve the problems of limited application scope, inability to quickly change the size and specifications of external thread assembly rods as needed, insufficient self-locking performance, etc. Achieve a wide range of applications, simple and quick loading and unloading operations, and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will now be described in further detail with reference to the drawings. These figures are schematic diagrams, which will be described only in a schematic manner, and therefore it only shows the configurations related to the present invention.

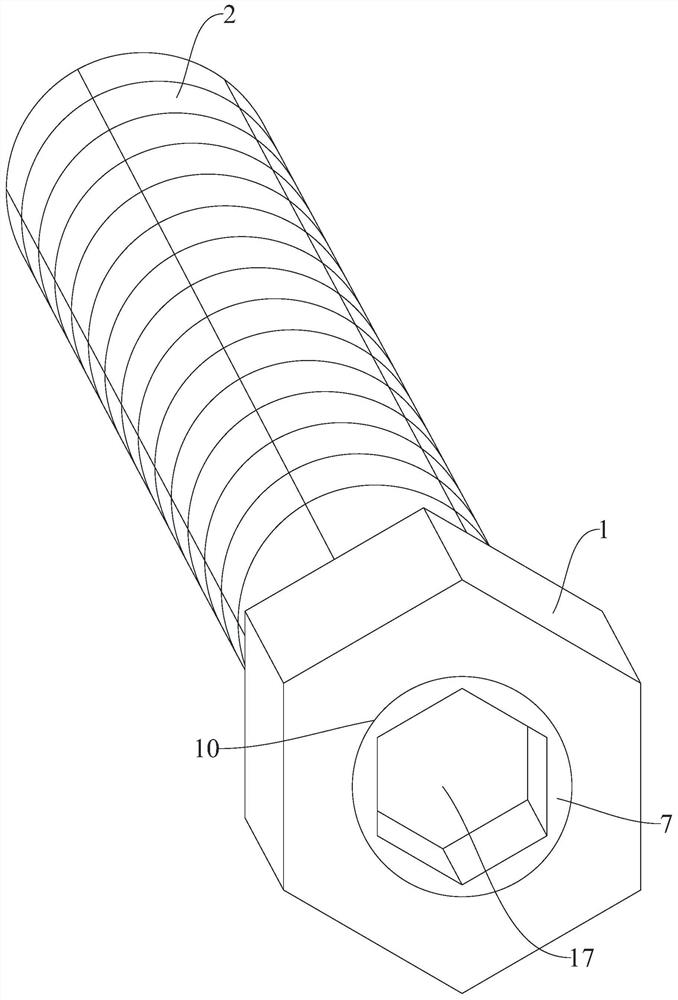

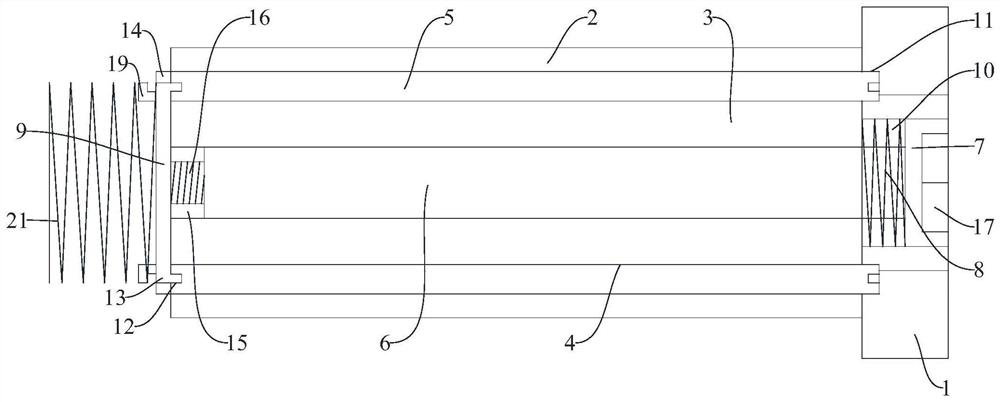

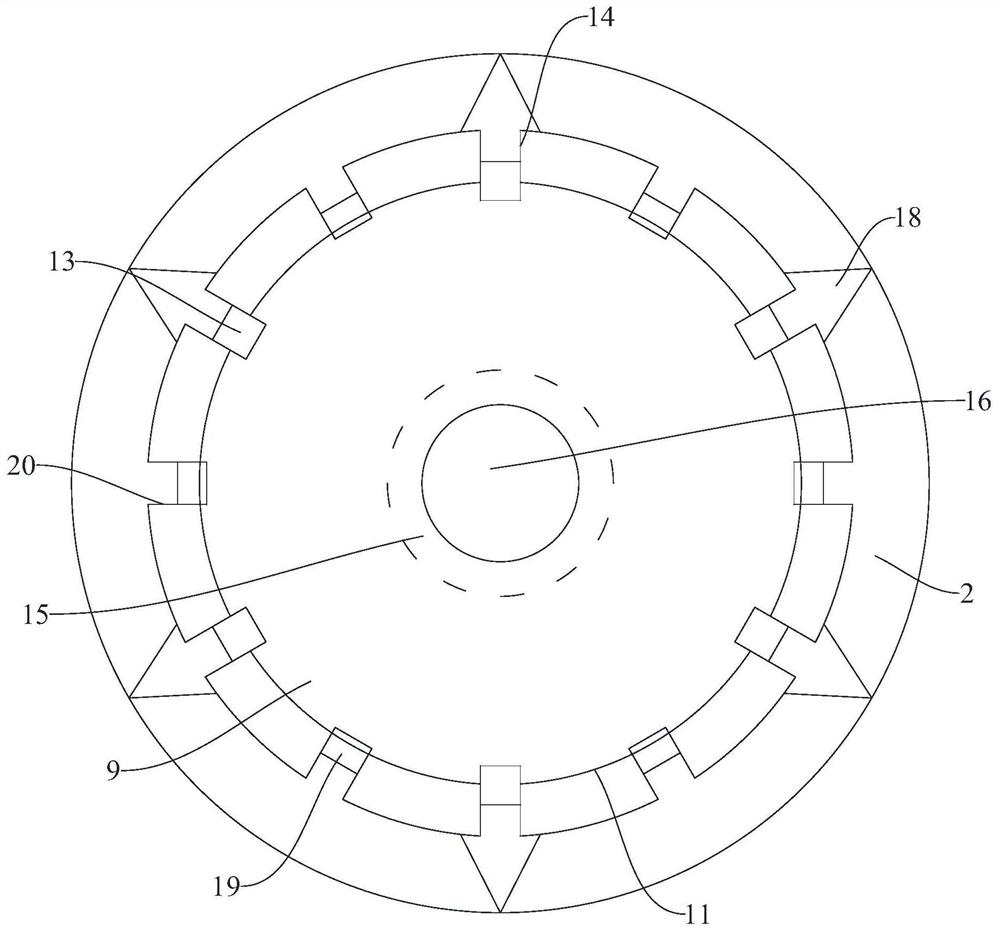

[0025] figure 1 , figure 2 and image 3 The lock bolt having a resilient quick release mechanism shown, comprising a bolt head and a top arcuate outer threaded mounting plate 2, the lower end of the top of the bolt head is fixed to an axially central position of the shaft tube 3 are integrally assembled configuration, the fitting shaft tube 3 defines the outer surface of the strip for mounting a plurality of arcuate mounting plate 2 external thread slot 4, the arcuate surface of the second inner panel has an arcuate outer thread fitting the mounting bar slot structure 4 integral internal projection Article 5, the fitting shaft 3 inside the tube plug event inner telescopic rod 6 has, inside the telescopic rod 6 n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com