Polyurethane sleeper and preparation method thereof

A technology of polyurethane and foamed polyurethane is applied in the field of rail sleepers and their preparation, which can solve the problems of difficulty in forming polyurethane foam and achieve the effects of low cost, improved mechanical properties and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

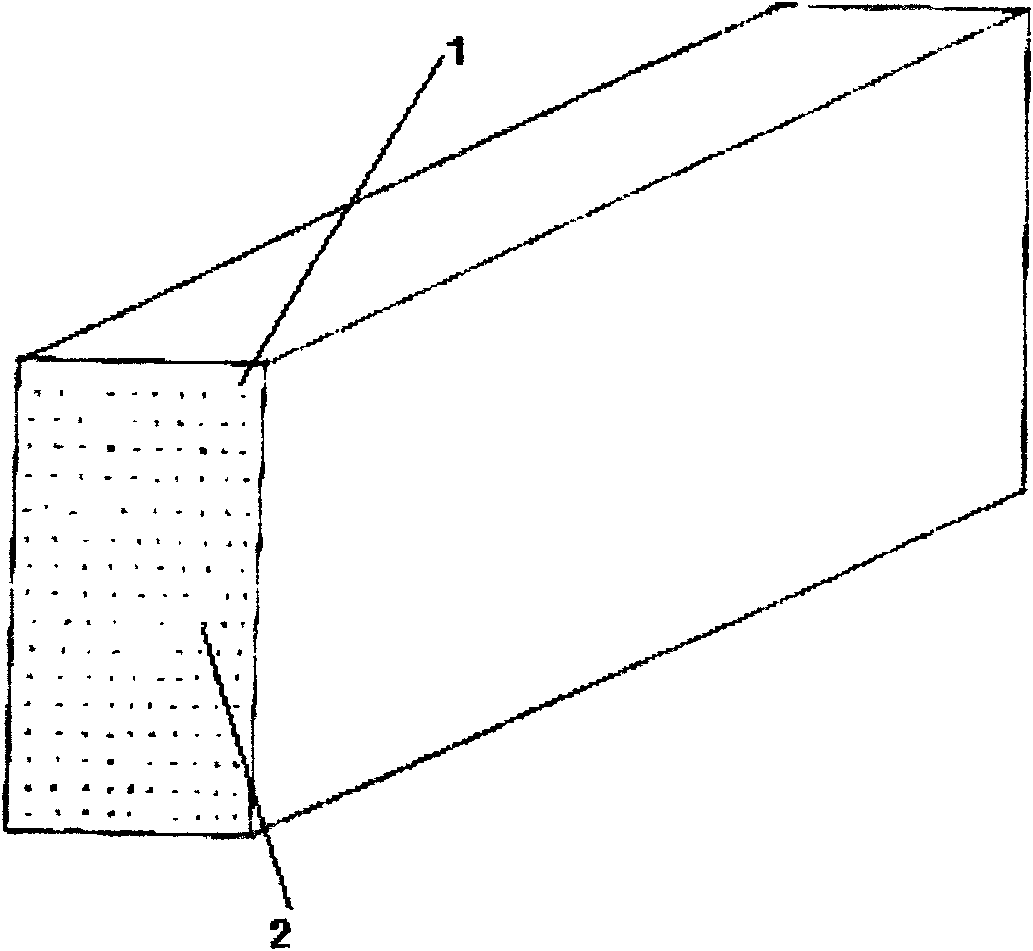

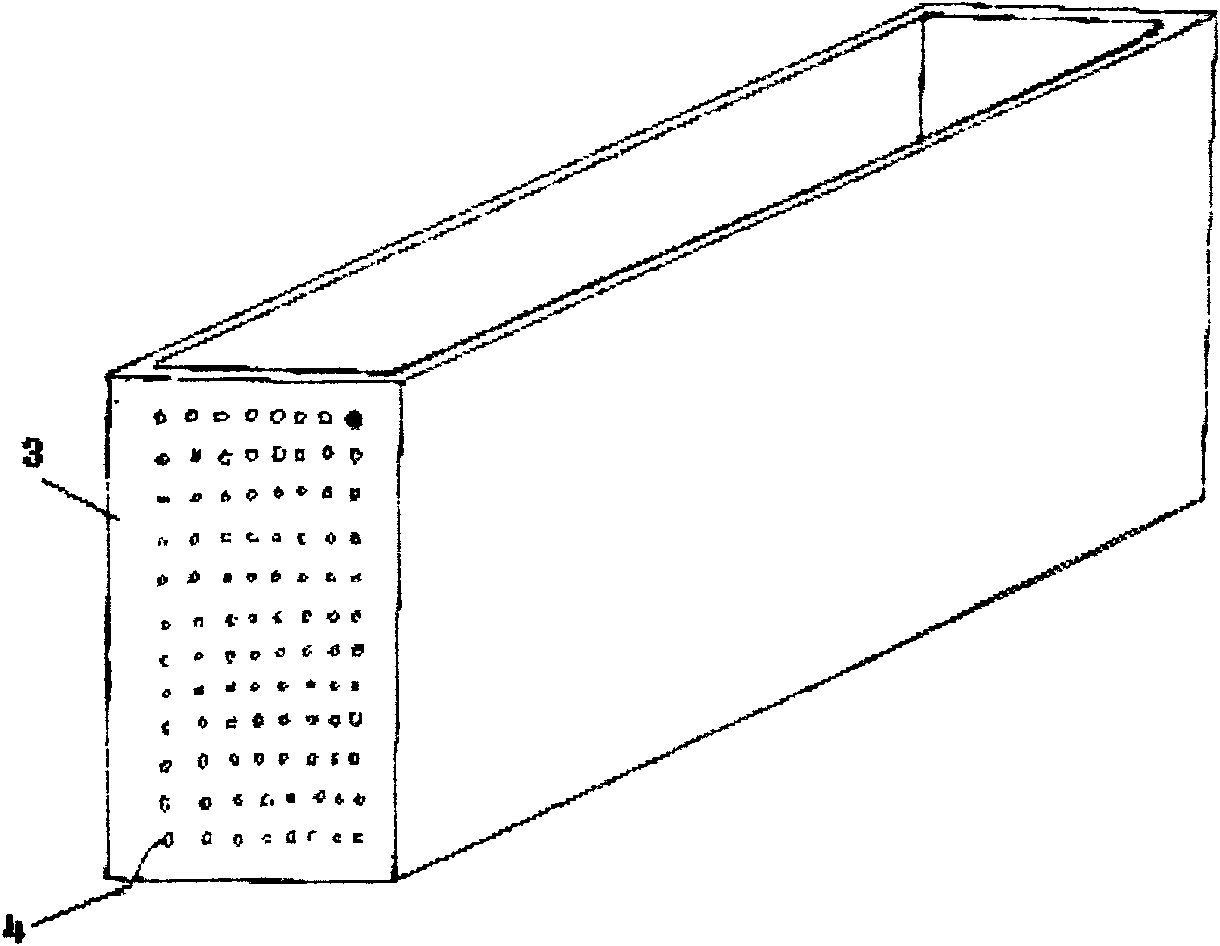

[0019] see figure 1 with figure 2 , figure 1 is the structural schematic diagram of the polyurethane sleeper, figure 2 Schematic diagram of the custom-made PVC frame used to manufacture the polyurethane sleeper. The numbers in the figure are: 1—polyurethane closed-cell foam; 2—long glass fiber roving; 3—end plates with threading holes at both ends of the frame; 4—threading holes.

[0020] figure 2 The PVC frame shown has a wall thickness of 5mm, and the inner wall dimensions: length is 1000mm, width is 130mm, and height is 260mm. The end plates 3 at both ends of the PVC frame are provided with threading holes 4, the diameter of the threading holes is 2mm, and the distance between the outermost threading holes and the edge is 5mm, and the holes are evenly spaced and arranged neatly. The number of threading holes on the single end of the PVC frame is 20×40, a total of 800, and the total length of glass fiber required to thread a PVC frame is about 850m. The glass fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com