Non-acid medium preparation method of flaky nickel phosphide array electrode material

An array electrode and nickel phosphide technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve toxicity and other problems, achieve the effect of improving quality and yield, avoiding waste of reagents, and high utilization rate of nickel atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Ultrasonic cleaning with acetone, hydrochloric acid (3mol / L), ethanol and deionized water for 10 minutes in sequence, and drying at 60°C for later use;

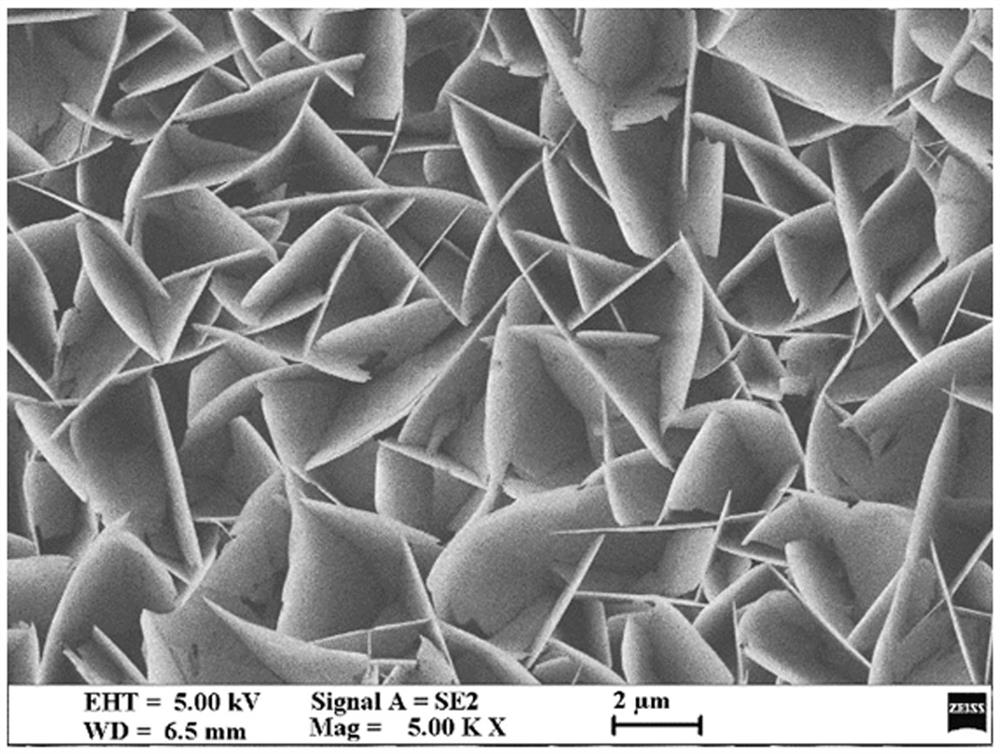

[0038] (2) Weigh 328mg of cetyltrimethylammonium bromide, add it into a beaker, then add 5mL of hydrogen peroxide, 5mL of deionized water, and 10mL of ethanol into the beaker, and sonicate for 10min to obtain a clear and transparent solution. Nickel foam with a size of 1×3 cm was added to the above solution, and ultrasonically treated for 10 min. Then the nickel foam and the solution were transferred to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction at 180°C for 20h. After naturally cooling to room temperature, take out the activated nickel foam, rinse with deionized water and ethanol three times each, and dry at 60°C for later use;

[0039] (3) Measure 5mL of hydrogen peroxide and 23mL of deionized water into a beaker, sonicate for 10min, then add 2mL of 1mmol / L cetyltrimethylammonium bro...

Embodiment 2

[0042] (1) Ultrasonic cleaning with acetone, hydrochloric acid (3mol / L), ethanol and deionized water for 10 minutes in sequence, and drying at 60°C for later use;

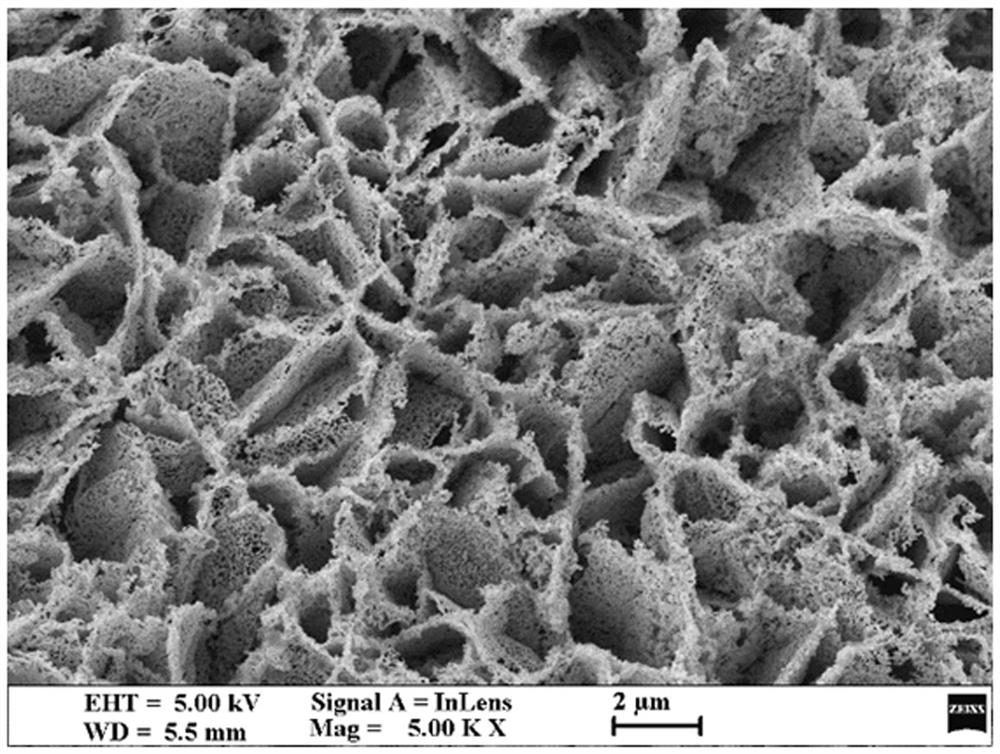

[0043] (2) Weigh 164mg of cetyltrimethylammonium bromide, add it into a beaker, then add 10mL of hydrogen peroxide and 10mL of ethanol into the beaker, and ultrasonicate for 10min to obtain a clear and transparent solution. Nickel foam with a size of 1×3 cm was added to the above solution, and ultrasonically treated for 10 min. Then the nickel foam and the solution were transferred to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction at 180°C for 24h. After naturally cooling to room temperature, take out the activated nickel foam, rinse with deionized water and ethanol three times each, and dry at 60°C for later use;

[0044] (3) Measure 5mL of hydrogen peroxide and 22mL of deionized water into a beaker, sonicate for 10min, then add 3mL of 1mmol / L cetyltrimethylammonium bromide solution, and ...

Embodiment 3

[0047] (1) Ultrasonic cleaning with acetone, hydrochloric acid (3mol / L), ethanol and deionized water for 10 minutes in sequence, and drying at 60°C for later use;

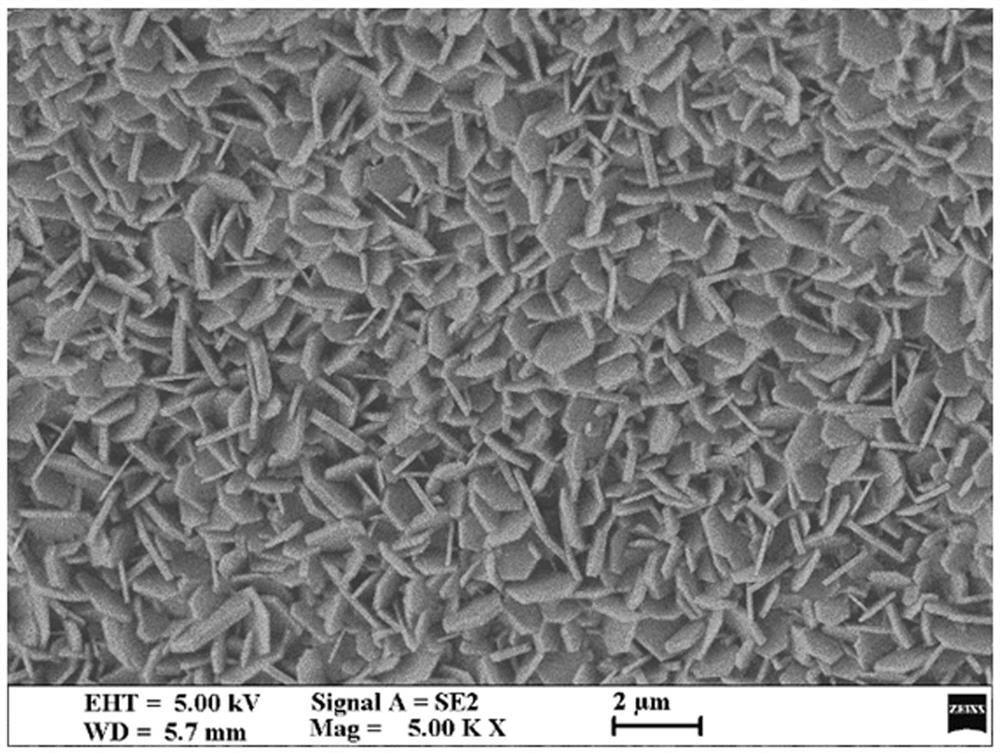

[0048] (2) Weigh 328mg of cetyltrimethylammonium bromide, add it into a beaker, then add 5mL of hydrogen peroxide, 5mL of deionized water, and 10mL of ethanol into the beaker, and sonicate for 10min to obtain a clear and transparent solution. Nickel foam with a size of 1×3 cm was added to the above solution, and ultrasonically treated for 10 min. Then the nickel foam and the solution were transferred to a polytetrafluoroethylene hydrothermal kettle for hydrothermal reaction at 180°C for 24h. After naturally cooling to room temperature, take out the activated nickel foam, rinse with deionized water and ethanol three times each, and dry at 60°C for later use;

[0049] (3) Measure 5mL of hydrogen peroxide and 24mL of deionized water into a beaker, sonicate for 10min, then add 1mL of 1mmol / L cetyltrimethylammonium bro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com