High-wear-resistance EVA (Ethylene Vinyl Acetate) foaming material for shoes and preparation method thereof

A technology for foaming materials and shoes, which is applied in the field of foaming materials for shoes, can solve the problems of wear resistance and compression resistance that need to be improved, and achieve the effects of improving compatibility, good wear resistance and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The embodiment of the present invention provides the preparation method of EVA foam material for shoes as described above, comprising the following steps:

[0048] S1, mixing all raw materials except bridging agent and blowing agent in each raw material weighed;

[0049] S2, adding the bridging agent and foaming agent to the material mixed in step S1 and then mixing;

[0050] S3, granulating the mixture obtained in step S2, and placing it for cooling;

[0051] S4. The particles cooled in step S3 are subjected to an IP primary molding process or an MD secondary molding process to obtain a highly wear-resistant EVA foam material for shoes.

[0052] Specifically, the preparation method of the EVA foam material for shoes with high wear resistance and pressure change resistance described in the embodiments of the present invention comprises the following steps:

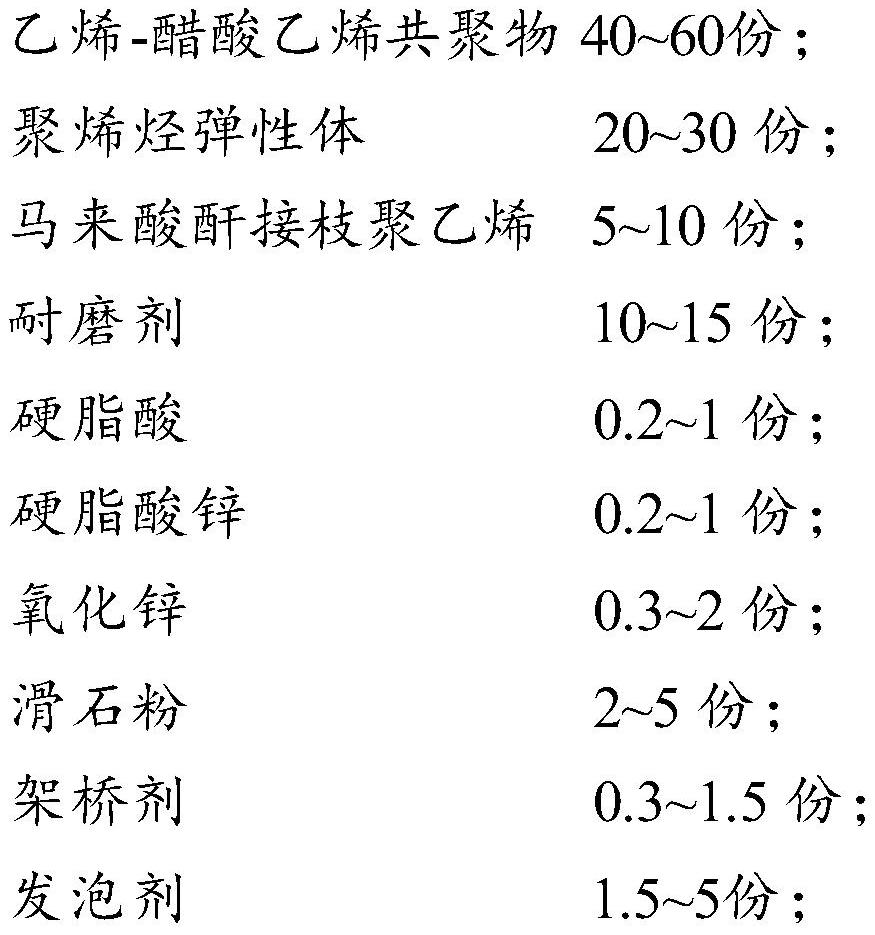

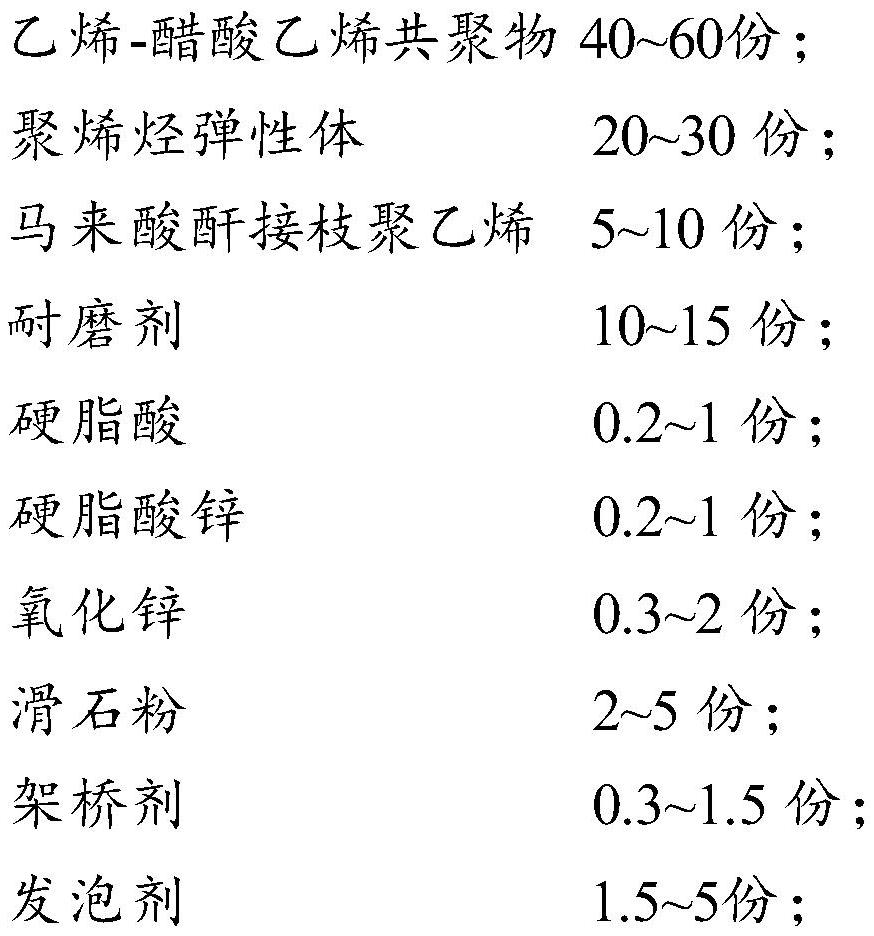

[0053] Step 1: weigh each raw material according to the mass parts of each component in the composition for pre...

Embodiment 1

[0066] A super-comfortable EVA foam material with high wear resistance and pressure change resistance, comprising the following raw materials in parts by weight:

[0067] Ethylene-vinyl acetate copolymer: 40 parts;

[0068] Polyolefin thermoplastic elastomer: 30 parts;

[0069] Maleic anhydride grafted polyethylene: 10 parts;

[0070] Wear-resistant agent: 10 parts;

[0071] Stearic acid: 0.5 parts;

[0075] Bridging agent: 0.8 parts;

[0076] Foaming agent: 2.5 parts;

[0077] Wherein, the model of ethylene-vinyl acetate copolymer is EVA7470M, produced by Formosa Plastics Corporation of Taiwan; the model of polyolefin block copolymer is infuse9507, produced by Dow Company; the maleic anhydride grafted polyethylene is E588, produced by DuPont; the wear-resistant agent is a composite material of polytetrafluoroethylene / styrene-butadiene rubber prepared by the emulsion method;...

Embodiment 2

[0090] A super-comfortable EVA foam material with high wear resistance and pressure change resistance, comprising the following raw materials in parts by weight:

[0091] Ethylene-vinyl acetate copolymer: 40 parts;

[0092] Polyolefin thermoplastic elastomer: 30 parts;

[0093] Maleic anhydride grafted polyethylene: 10 parts;

[0094] Wear-resistant agent: 15 parts;

[0095] Stearic acid: 0.5 parts;

[0097] Zinc oxide: 1.6 parts;

[0099] Bridging agent: 1.2 parts;

[0100] Foaming agent: 3.2 parts;

[0101] Among them, the model of ethylene-vinyl acetate copolymer is EVA7470M and EVA40W, and its mass ratio is 2:1. EVA7470M is produced by Taiwan Formosa Plastics Company, and EVA40W is produced by DuPont Company; the model of polyolefin block copolymer is infuse9107, manufactured by Dow Company Production; maleic anhydride grafted polyethylene as E588, produced by DuPont; the wear-resistant agent is a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com