Sludge soft soil curing agent and sludge soft soil curing method

A technology of curing agent and soft soil, applied in the field of silt soft soil curing agent and silt soft soil curing, can solve problems such as low level of resource utilization, and achieve the effect of reduced production cost and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

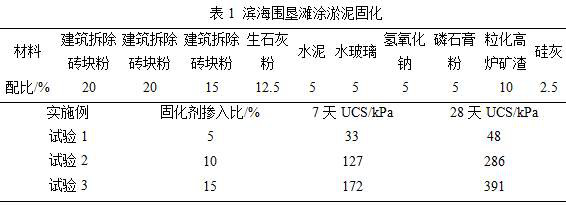

[0089] Prepare the curing agent according to the material ratio in Table 1. The silt is taken from the tidal flat area of coastal reclamation. The silt is in the shape of fluid plastic with a moisture content of 69.1%. Take a certain amount of the silt soft soil, mix it with curing agent powder according to the mass ratio of wet soil, and mix the silt and curing agent evenly. There are three kinds of curing agent mixing ratios, as shown in Table 1. Prepare 6 samples from the solidified sludge in the test of the mixing ratio of each curing agent. The diameter of the sample is 39.1mm and the height is 80mm. Among them, 3 samples are used for unconfined resistance In the compressive strength test, the average strength of the solidified soil under the mixing ratio of each curing agent is shown in Table 1.

[0090]

Embodiment 2

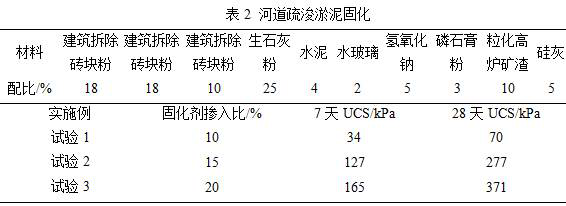

[0092] Prepare the curing agent according to the material ratio in Table 2. The silt is taken from the dredging silt of the river channel, which is in the shape of flow plastic and has a moisture content of 81.6%. Take a certain amount of the silt soft soil, mix it with curing agent powder according to the mass ratio of wet soil, and mix the silt and curing agent evenly. There are three kinds of curing agent mixing ratios, as shown in Table 2. Prepare 6 samples from the solidified sludge in the test of the mixing ratio of each curing agent. The diameter of the sample is 39.1mm and the height is 80mm. Among them, 3 samples are used for unconfined resistance In the compressive strength test, the average strength of the solidified soil under the mixing ratio of each curing agent is shown in Table 2.

[0093]

Embodiment 3

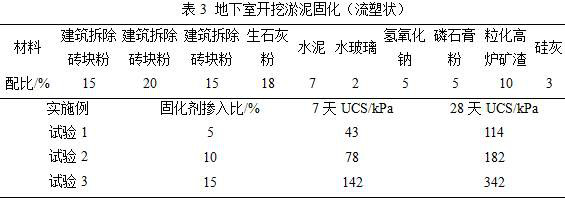

[0095] Prepare the curing agent according to the material ratio in Table 3. The silt is excavated from the basement, which is excavated silt with high water content, with a water content of 63.3%, and it is in the shape of fluid plastic. Take a certain amount of the silt soft soil, mix it with curing agent powder according to the mass ratio of wet soil, and mix the silt and curing agent evenly. There are three kinds of curing agent mixing ratios, as shown in Table 3. Prepare 6 samples from the solidified sludge in the test of the mixing ratio of each curing agent. The diameter of the sample is 39.1mm and the height is 80mm. Among them, 3 samples are used for unconfined resistance Compressive strength test. Table 3 shows the average strength of the stabilized soil under the mixing ratio of each curing agent.

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com