Raw material crushing and collecting device for solid red brick production

A collection device and red brick technology, applied in grain processing, etc., can solve problems such as easy-to-wear parts, affect production efficiency, and laborious dumping of raw materials, so as to reduce workload, improve production efficiency, and consume less energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

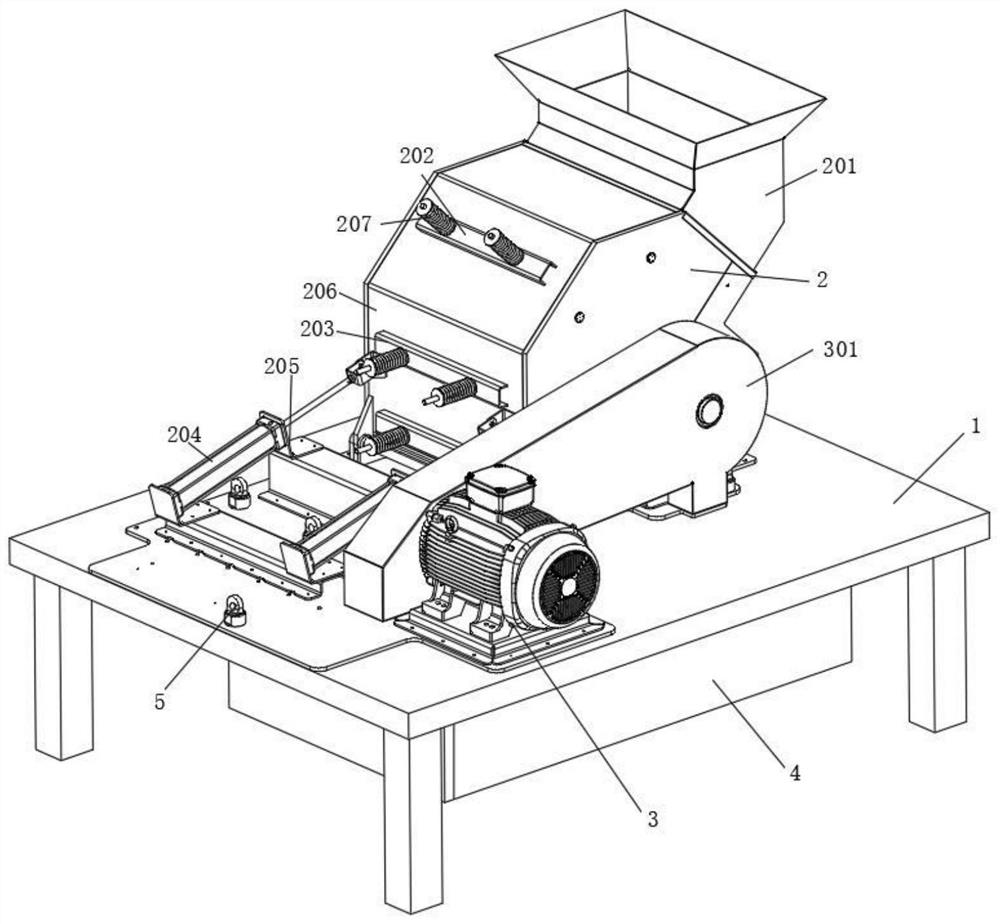

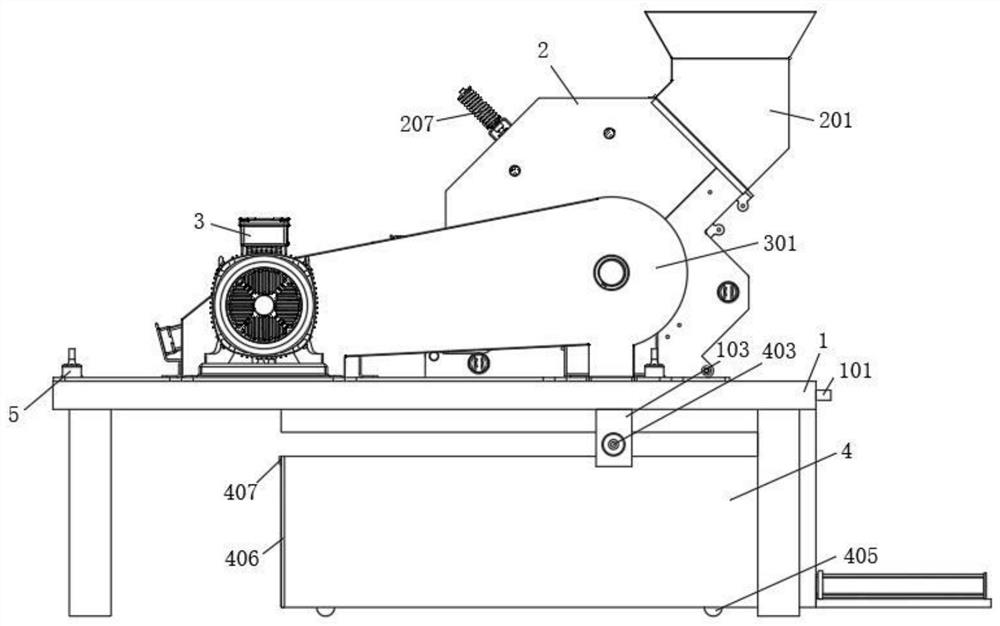

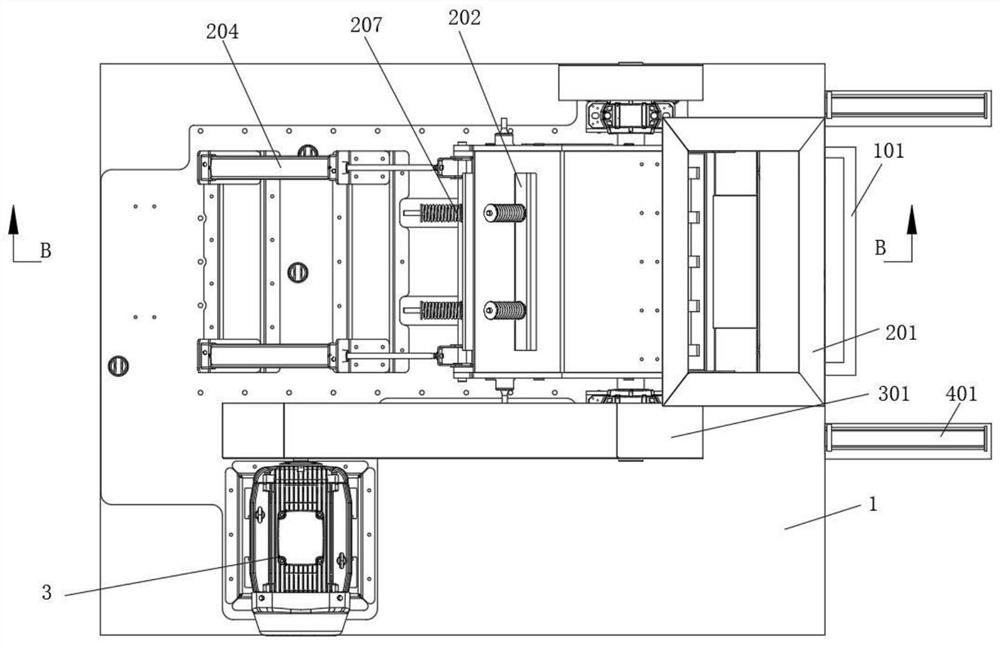

[0034] refer to Figure 1-6 , a raw material crushing and collecting device for solid red brick production. In order to improve the efficiency of raw material crushing, facilitate the mixing and collection of crushed raw materials, and prolong the service life of the device, a support platform 1 and a top side of the support platform 1 are set here The crushing box 2 and the motor 3 that drives the crushing box 2 are fixedly connected, the bottom side of the support table 1 is slidably connected with the collection box 4, and the interior of the support table 1 is provided with a device that communicates with the crushing box 2 and the collection box 4. The cavity of the collection box 4 is provided with side support plates 103 fixedly connected with the support table 1 on both sides of the collection box 4. In order to facilitate multiple collisions and crushing of the raw materials, and to perform preliminary mixing of the raw materials during the crushing process, here in th...

Embodiment 2

[0037] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, in order to achieve impact crushing, ensure the qualified rate of raw material crushing, and prevent raw materials from breaking away from the crushing area, an impact crushing structure including a rotating rod 208, a pulley 209, Impeller 210, hammer plate 211, upper impact plate 212, limit baffle plate 213, folding hanging door 214, lower impact plate 215, hook 217 and hanging ring 218, in order to ensure that the work of rotating rod 208 will not affect the single operation of crushing box 2 To move, the two ends of the rotating rod 208 are set here to run through the crushing box 2, and one end is fixedly connected with the pulley 209. The pulley 209 is a double-track pulley, and it is connected with the output shaft of the motor 3 through a conveyor belt for synchronous rotation. To provide sufficient power for raw materials, the impeller 210 is fixedly connected to the...

Embodiment 3

[0040] Such as Figure 1-6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, in order to facilitate the collection, mixing and transshipment of raw materials, an auxiliary aggregate structure is provided here including cylinder two 401, auxiliary push block 402, shaft rod 403, shunt brush 404, outlet Material baffle plate 406 and lock catch 407, in order to reduce the work burden of workers, cylinder 2 401 is fixedly connected with the outer wall of collecting box 4 here, and its output shaft extends to the inner side of collecting box 4 and is fixedly connected with auxiliary push block 402. The side wall of the material box 4 is provided with hollowed grooves. In order to make full use of the power source and save work costs, the shaft rod 403 is arranged on the inside of the hollowed grooves, and one end is rotationally connected with the side support plate 103, and the other end is connected with the belt pulley 209. A belt 216 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com