Water jet cutting machine and jet generation device thereof

A generation device and jet flow technology, applied in metal processing, etc., can solve the problems of equipment use, high maintenance costs, high requirements for plunger rod materials, short plunger rod strokes, etc., achieve significant energy saving effects, reduce material requirements, The effect of reducing the failure rate and wearing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

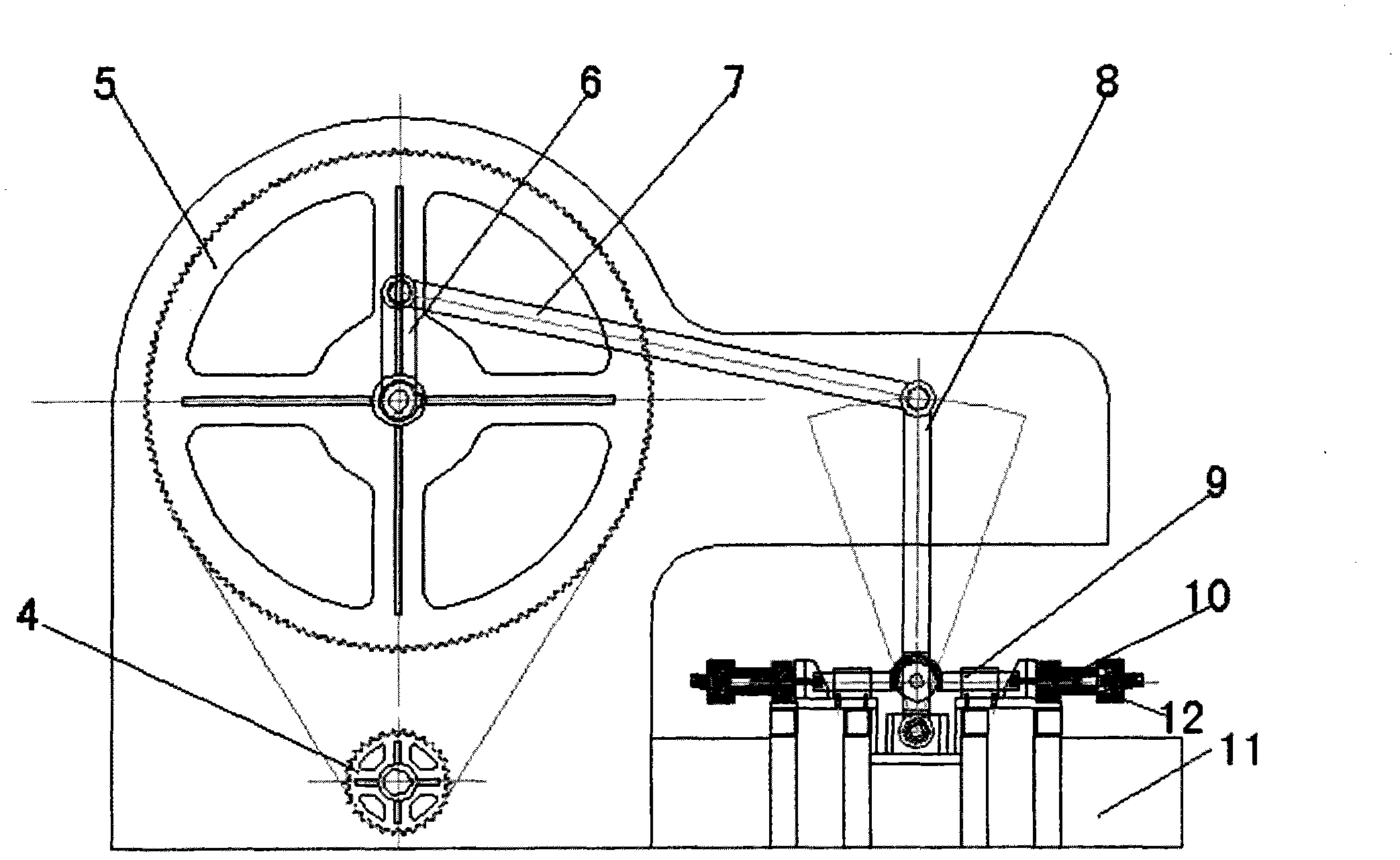

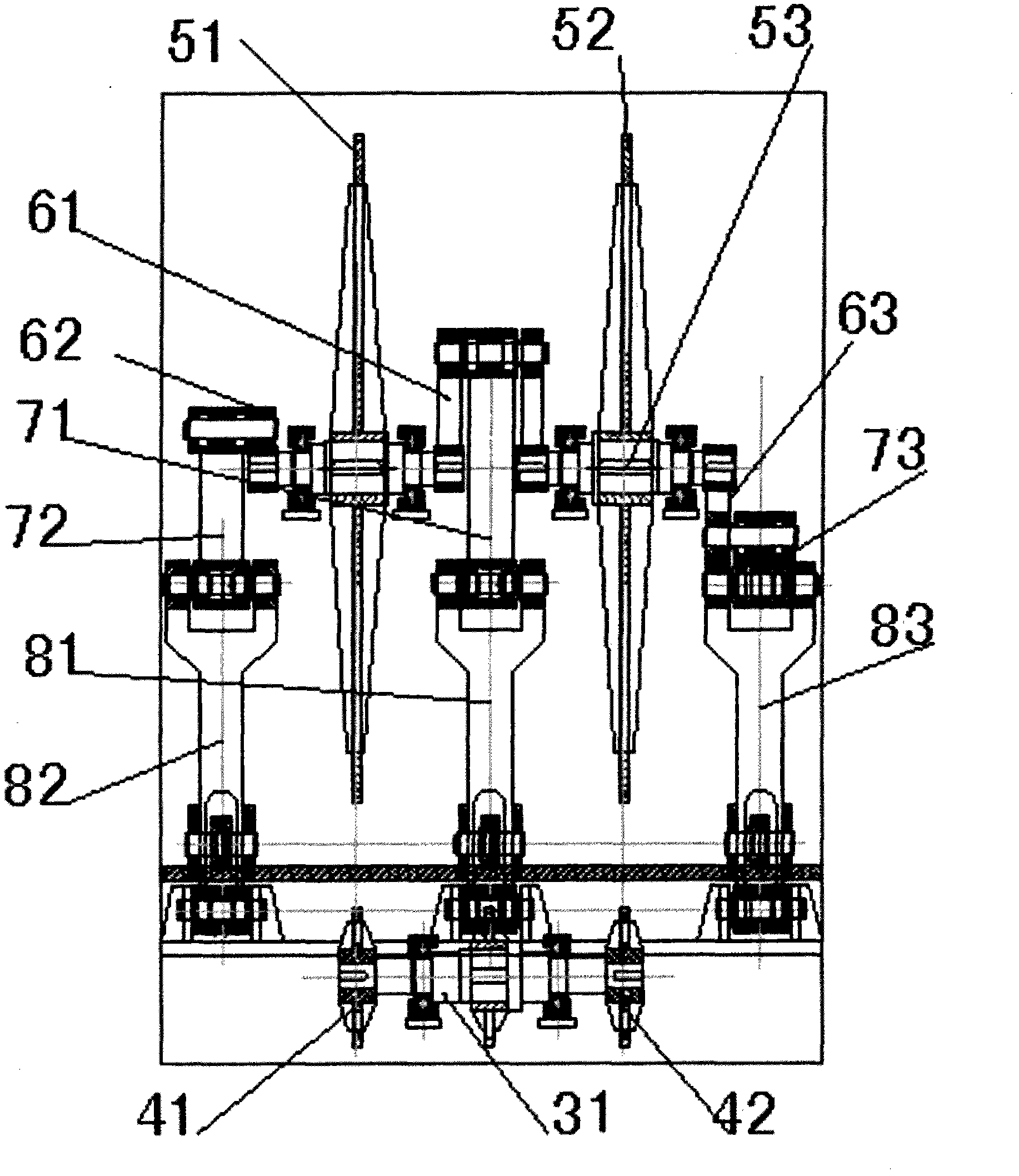

[0034] figure 1 , 2 , 3 respectively show a front view, a top view, and a left view of the jet flow generating device according to the first embodiment of the present invention.

[0035] The jet generating device includes a frame 11, a driving device 1 arranged on the frame 11, a driving wheel 2 arranged on the driving device 1, a first transmission shaft 31 arranged on the frame 11, a first transmission shaft 31 arranged on the first transmission shaft 31 The driving wheel 3 and the driven wheel 4 (the driven wheel 4 includes the first driven wheel 41 and the second driven wheel 42), the work wheel 5 arranged on the frame 11 (the work wheel includes the first work wheel 51 and the second work wheel 51) Two working wheels 52), the second transmission shaft 53, the rocking arm 6 that is arranged on the working wheel 5 (the rocking arm 6 includes the first rocking arm 61, the second rocking arm 62 and the third rocking arm 63), connecting rod 7 , Working lever 8, push rod 9, ...

no. 2 example

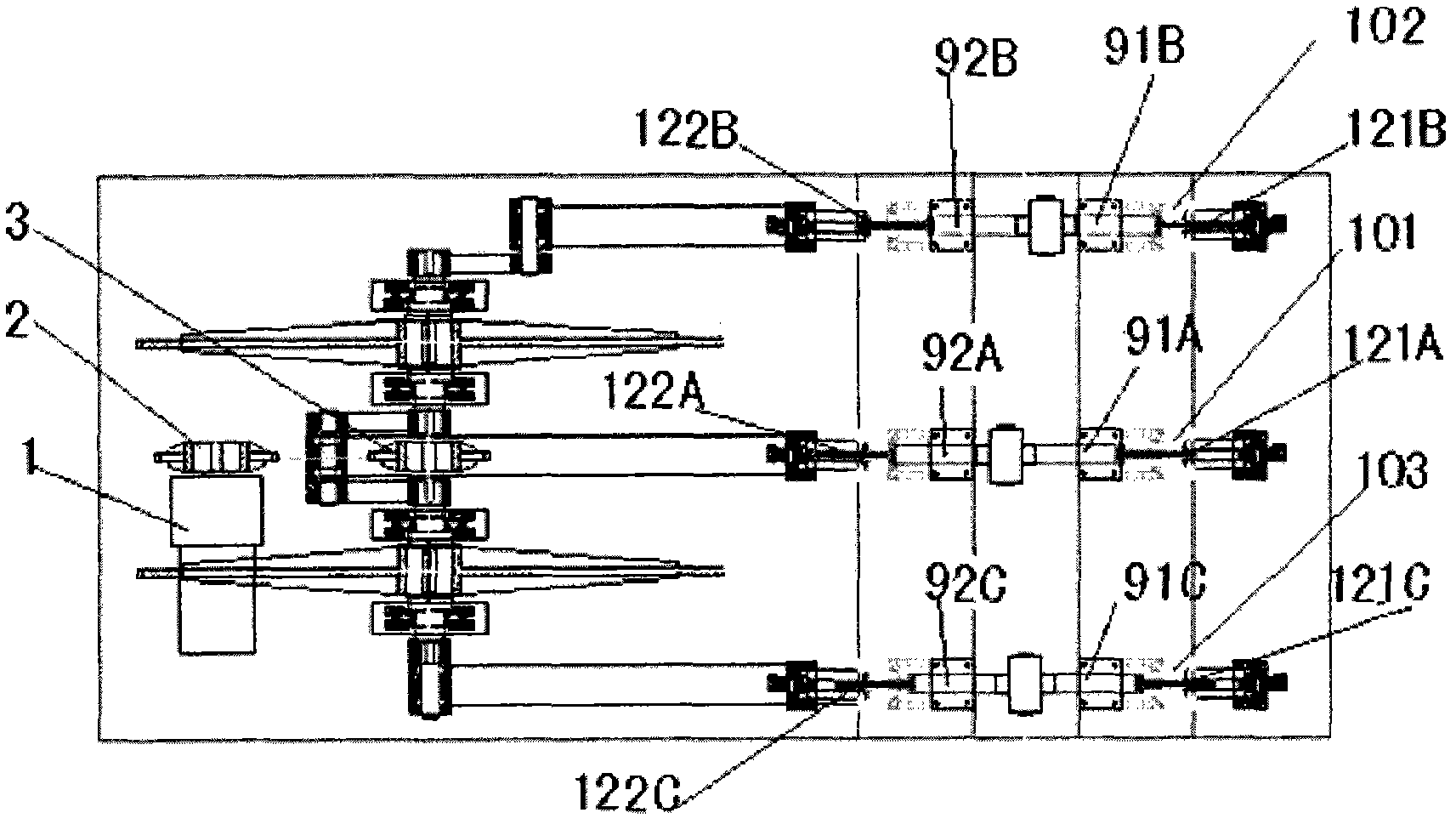

[0064] as attached Figure 5 , 6 , which shows the jet flow generating device of the second embodiment of the present invention. Wherein, the same or similar components as in the first embodiment are identified by the same or similar reference numerals.

[0065] When the user needs a small flow (such as less than 4 liters / min and pressure: 55000Psi), the high-torque eccentric wheel in the jet generating device of the first embodiment of the present invention can be used to directly push three plunger rods to generate high-pressure water jets. Mechanism; also can adopt the working lever structure in the jet flow generating device of the first embodiment of the present invention to realize the above function.

[0066] In the second embodiment, the jet flow generating device includes a frame, a driving device 1 arranged on the frame, a driving wheel 2 arranged on the frame, a driving wheel 3 and a driven wheel 4 arranged on the driving wheel, and The work wheel 5 on the frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com