Static crystallizer and static crystallization method

A static crystallization and crystallization technology, applied in chemical instruments and methods, crystallization separation, separation methods, etc., can solve problems such as uneven thickness of the crystallization layer in the crystallization tube, affecting product purity and yield, crystallization tube falling off, etc., to avoid Reduced heat transfer efficiency, shortened separation cycle, and increased compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0098] According to a preferred embodiment provided by the present invention, the static crystallization method includes:

[0099](1) The first heat exchange medium is respectively introduced into the N-layer sub-cavities, and the material to be crystallized is cooled and crystallized in a static crystallizer, and the cavity 2 of the static crystallizer is provided with a crystallization chamber for the material to be crystallized At least one heat exchange tube 11, the heat exchange tube 11 is provided with a stretchable component 3, and the stretchable direction of the stretchable component 3 is not parallel to the axial direction of the heat exchange tube 11;

[0100] (2) introducing the second heat exchange medium into the N-layer subcavities respectively, heating and sweating the first crystal layer obtained in step (1), and discharging the obtained sweat out of the static crystallizer;

[0101] (3) heating and melting the second crystal layer obtained in step (2).

[01...

Embodiment 1

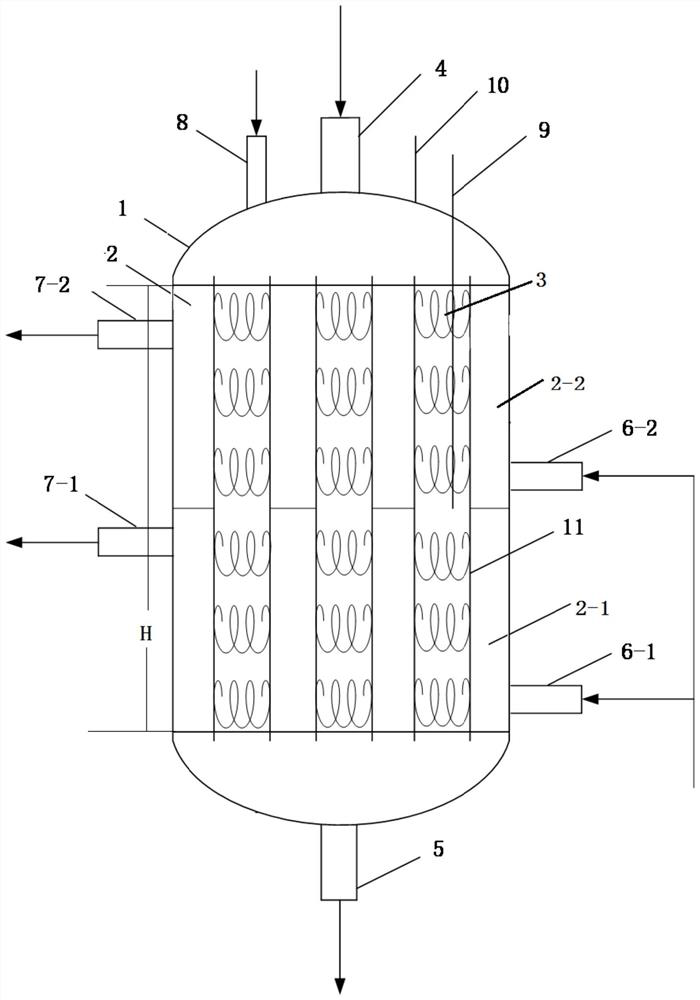

[0106] In the static crystallizer used in this embodiment, the cavity 2 is not layered, the height H of the cavity 2 is 1 m, and the inner diameter is 0.2 m. Three heat exchange tubes 11 are arranged in the cavity 2; the sum of the cross-sectional areas of the heat exchange tubes 11 accounts for 65% of the cross-sectional area of the cavity 2, and each heat exchange tube 11 is provided with There are three layers of stretchable parts 3 (spiral shape) arranged up and down, the porosity of the heat exchange tube is 85%, and the stretchable parts 3 are arranged horizontally, and the stretchable direction is the same as the heat exchange tube. The axial direction of the tube 11 is vertical, and the end surface of the stretchable part 3 in the stretchable direction is in direct contact with the heat exchange surface of the heat exchange tube 11, and the end of the stretchable part 3 in the heat exchange tube The covering area of the part accounts for 80% of the area of the he...

Embodiment 2

[0114] In the static crystallizer that present embodiment adopts, as figure 1 As shown, the cavity 2 is divided into two layers (i.e. N=2) sub-cavities, which are respectively denoted as the upper layer sub-cavity 2-2 and the lower layer sub-cavity 2-1, and the upper layer sub-cavity 2-2 There are an upper layer heat exchange medium inlet 6-2 and an upper layer heat exchange medium outlet 7-2, the upper layer heat exchange medium inlet 6-2 is located below the upper layer heat exchange medium outlet 7-2; the lower layer subcavity 2 -1 is provided with a lower heat exchange medium inlet 6-1 and a lower heat exchange medium outlet 7-1, and the lower heat exchange medium inlet 6-1 is located below the lower heat exchange medium outlet 7-1. The height of each sub-cavity is 0.5 meters, and the inner diameter of the cavity 2 is 0.5 meters. Seven heat exchange tubes 11 are arranged in the cavity 2; the sum of the cross-sectional areas of the heat exchange tubes 11 accounts for 85% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com